Method and assembly for preventing the production of windborne debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

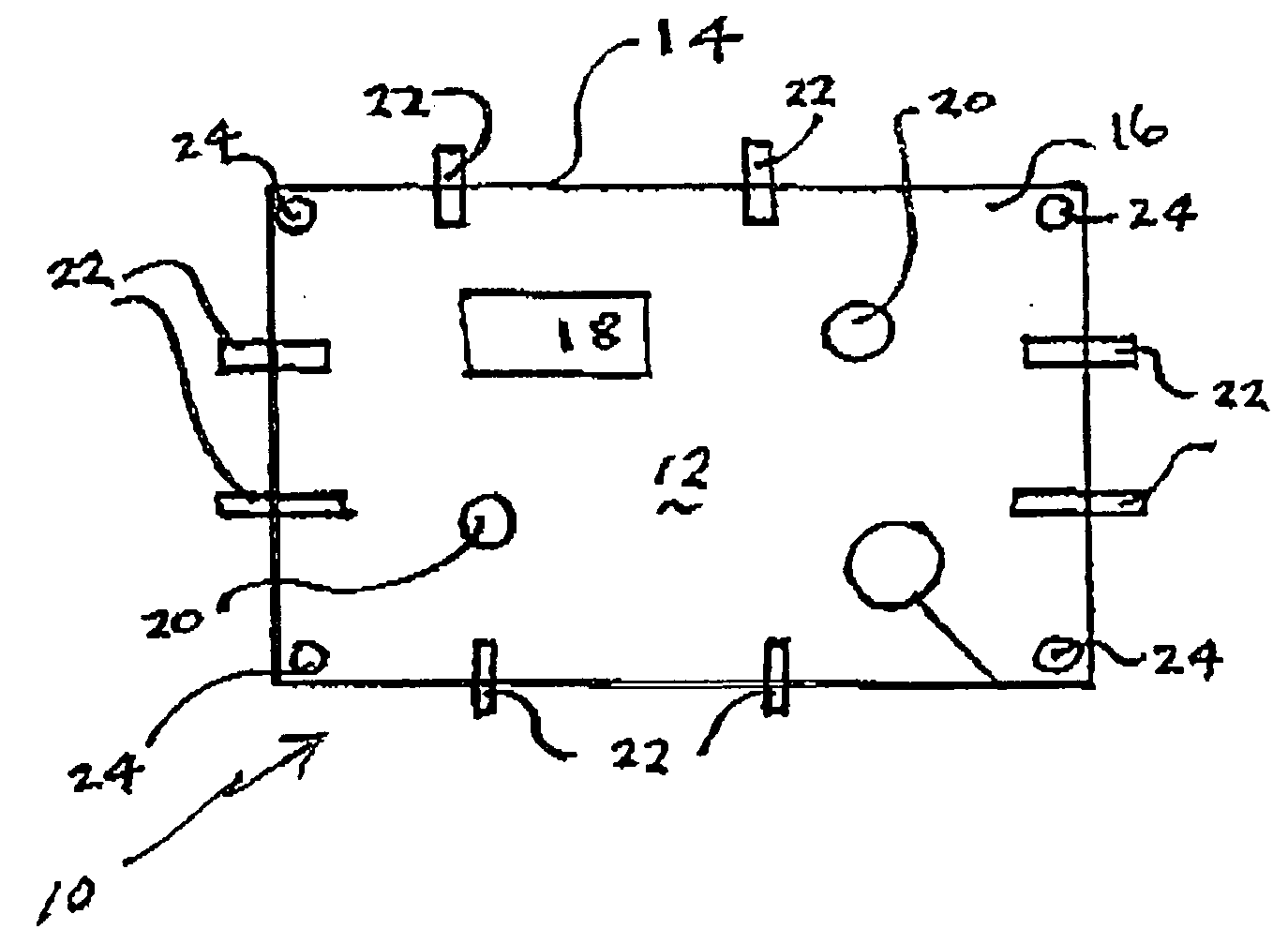

[0040]With reference to FIG. 1, this shows, generally, as 10, a BIG-BOX retail store, having a flat roof 12 with a roof periphery 14 and having a “tar and gravel” surface 16. Upon roof 12 is a plurality of typical roof articles, namely, air conditioner unit 18, air vents 20, window cleaning equipment supports 22, and rain water run-off apertures 24 for water down-pipes (not shown).

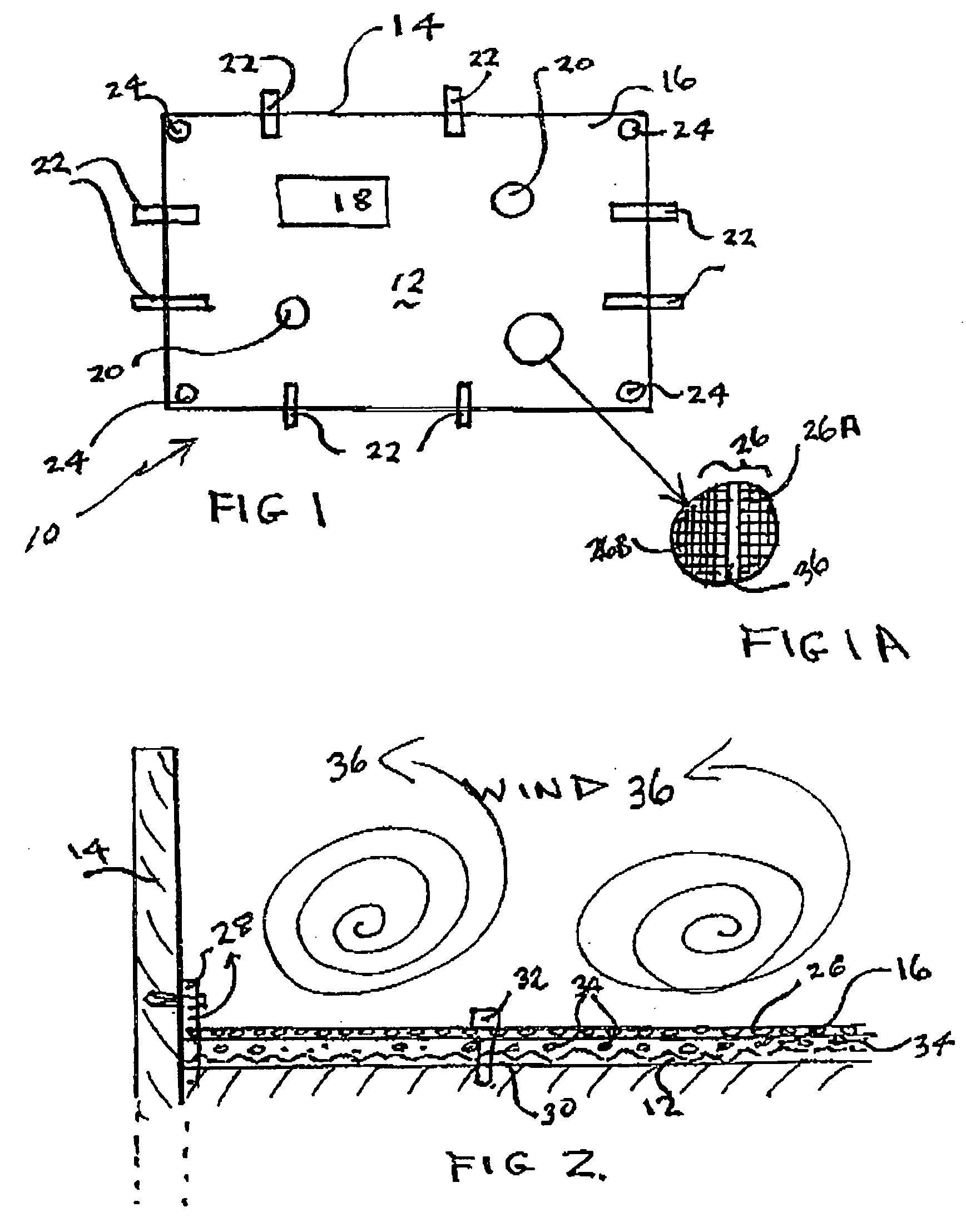

[0041]With reference also to FIG. 1A and FIG. 2, located between aforesaid roof articles 18, 20, 22 and 24 and roof periphery 14 adjacent and 2-3 cm above surface 16 is a flexible, webbed netting 26, formed of a water resistant braided polyethylene. Netting 26 is attached to roof 12 and roof periphery 14 and by attachment bolts 28 and to a middle portion 30 by screw bolts 32. Netting 26 is at a distance of about 2 cm. above surface 16. Between netting 26 and surface 16 is loose particulate, B3 roof gravel 34, airborne by turbulent wind forces 36.

[0042]FIG. 1A shows netting 26 comprising two smaller portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com