Rotary pump having a valve rotor and one or more vane rotors and methods for pumping fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

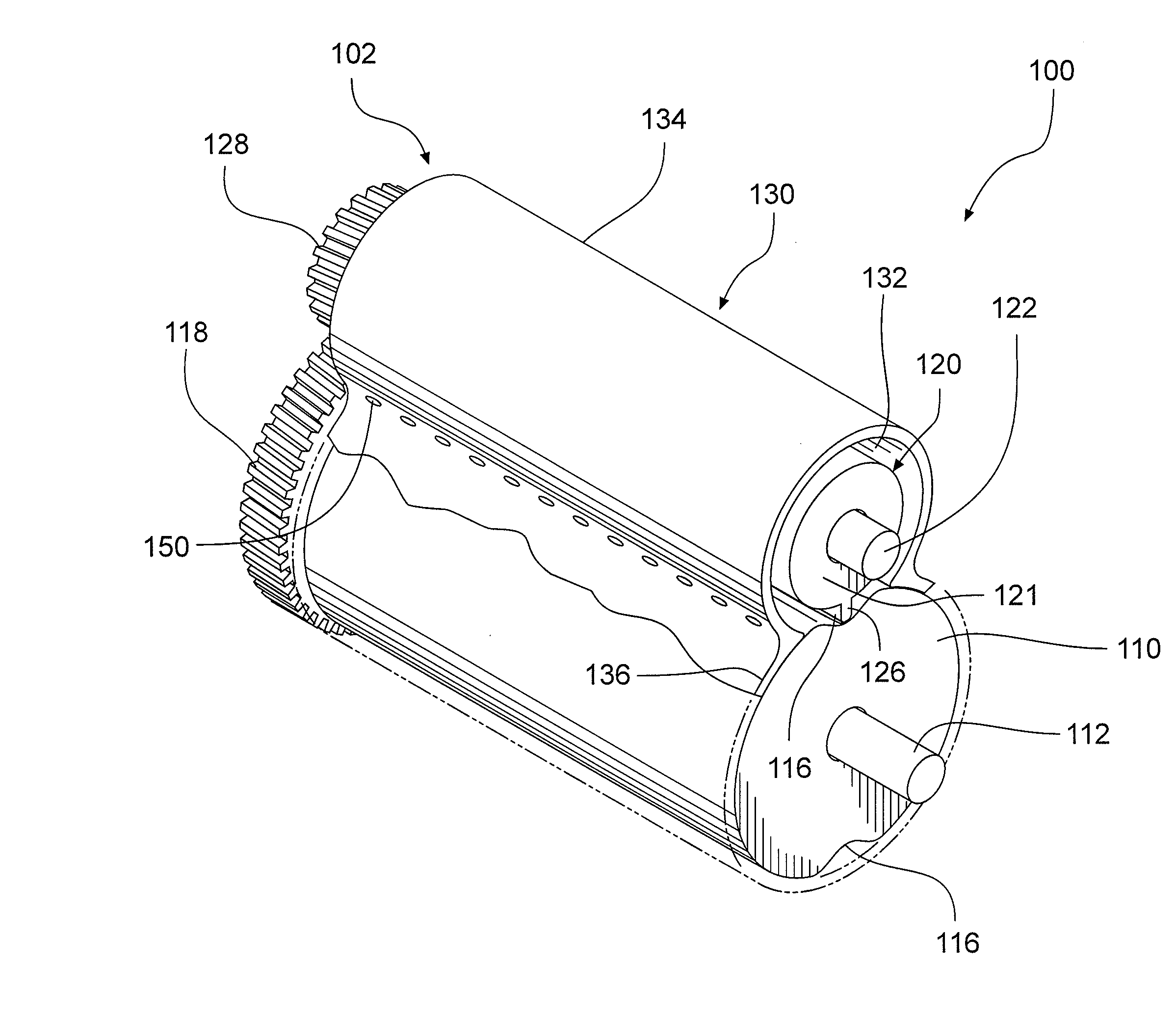

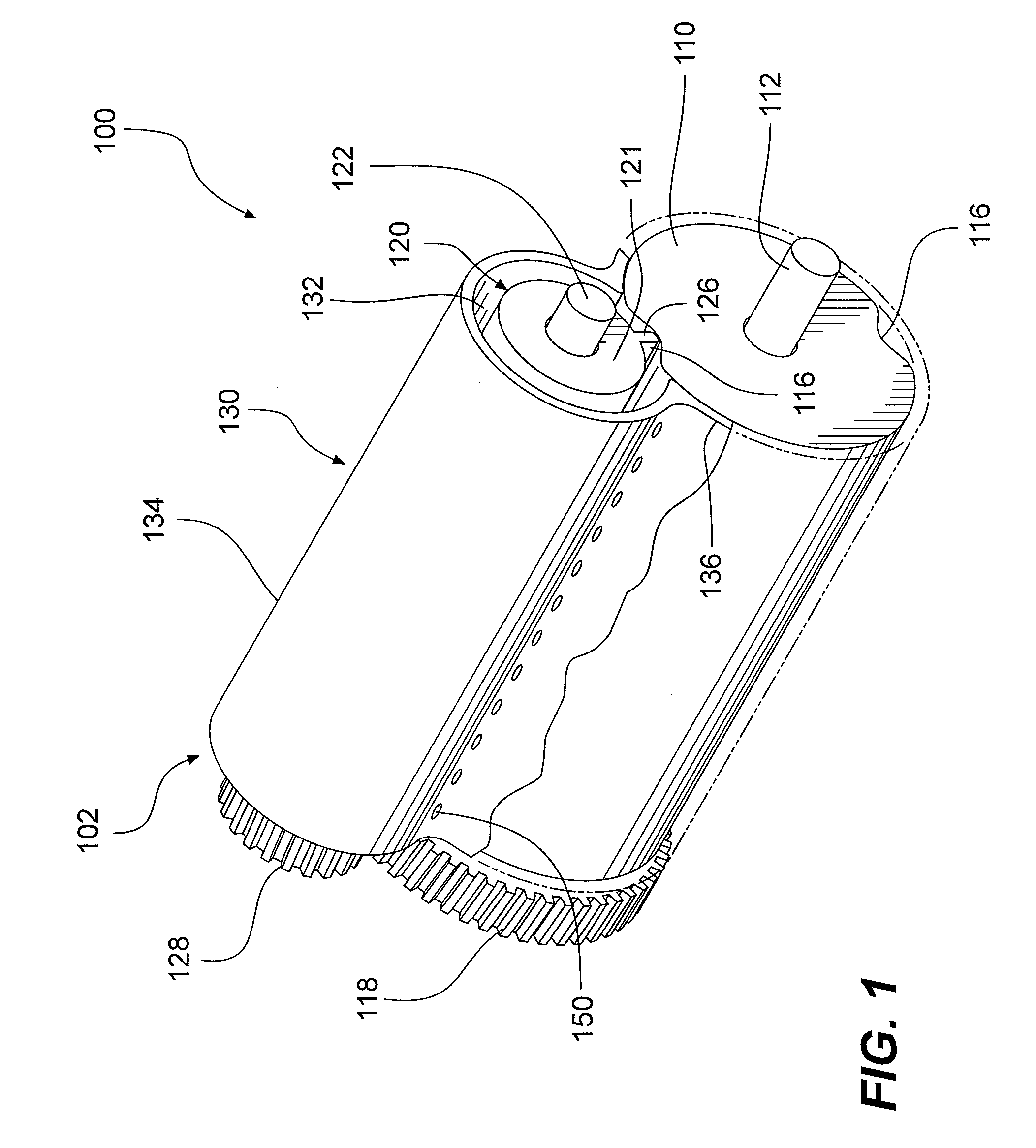

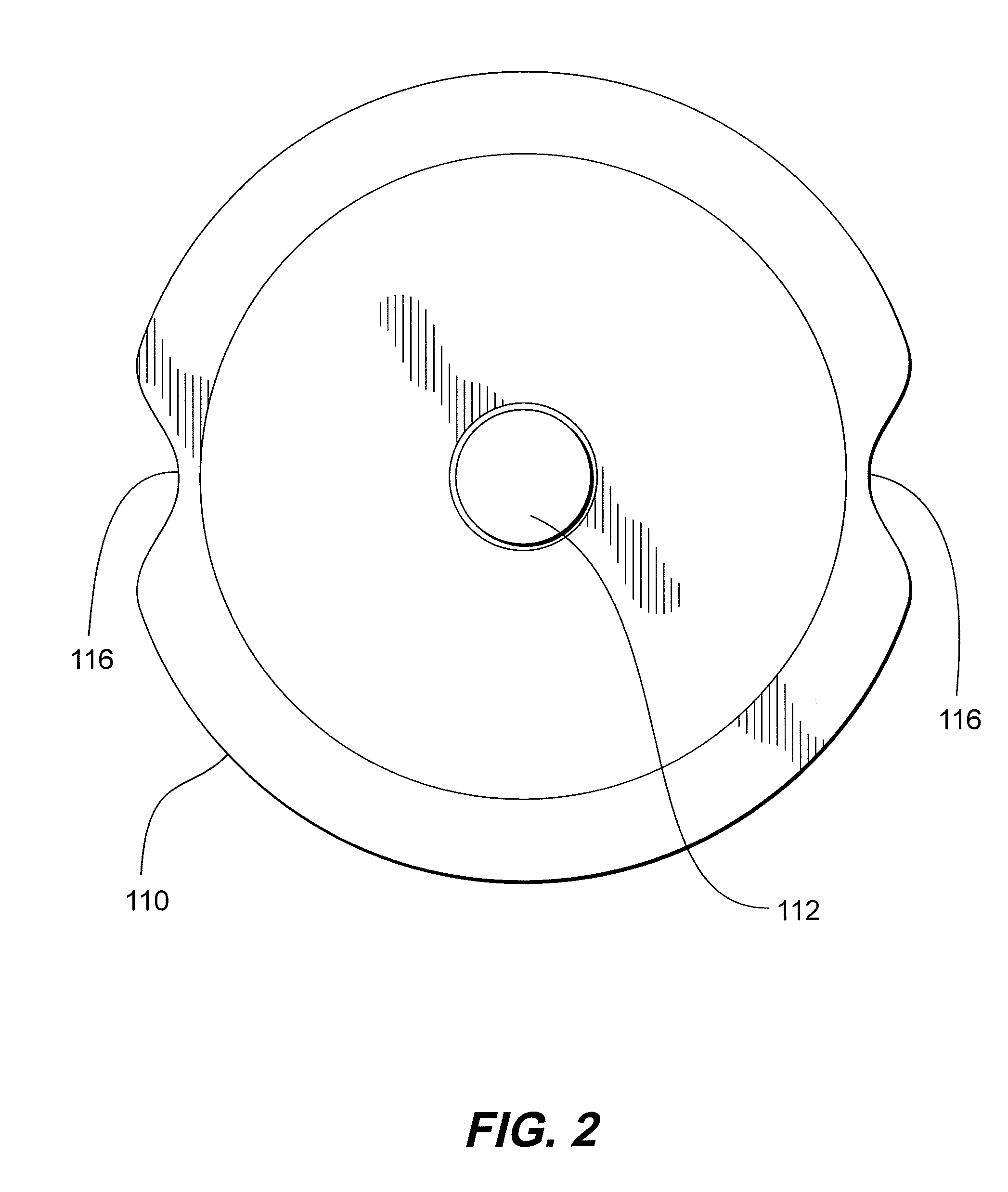

[0014]This invention provides rotary pumps and methods for pumping fluids comprising one or more vane rotors that each have one or more vanes that divide a pump space into an inlet space and a discharge space.

[0015]This invention separately provides rotary pumps and methods for pumping fluids comprising one or more vane rotors that each have one or more vanes that divide a pump space into an inlet space, a displacement space, and a discharge space.

[0016]This invention separately provides rotary pumps and methods for pumping fluids comprising at least one vane rotor that each has a substantially large displacement volume.

[0017]This invention separately provides rotary pumps and methods for pumping fluids comprising one or more vane rotors that each have a vane that interacts with or engages at least one slot formed in a valve rotor as the valve rotor and the one or more vane rotors rotate relative to each other.

[0018]This invention separately provides rotary pumps and methods for pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com