Sealing rubber sleeve of low-temperature soluble bridge plug and preparation method of sealing rubber sleeve

A technology of sealant and bridge plug, which is applied to the sealant cartridge of low-temperature soluble bridge plug and its preparation field, can solve the problems of insoluble, soluble bridge plug needing improvement, and high dissolution temperature, and achieves good assembly performance and low-temperature dissolution performance. , Good assembly, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

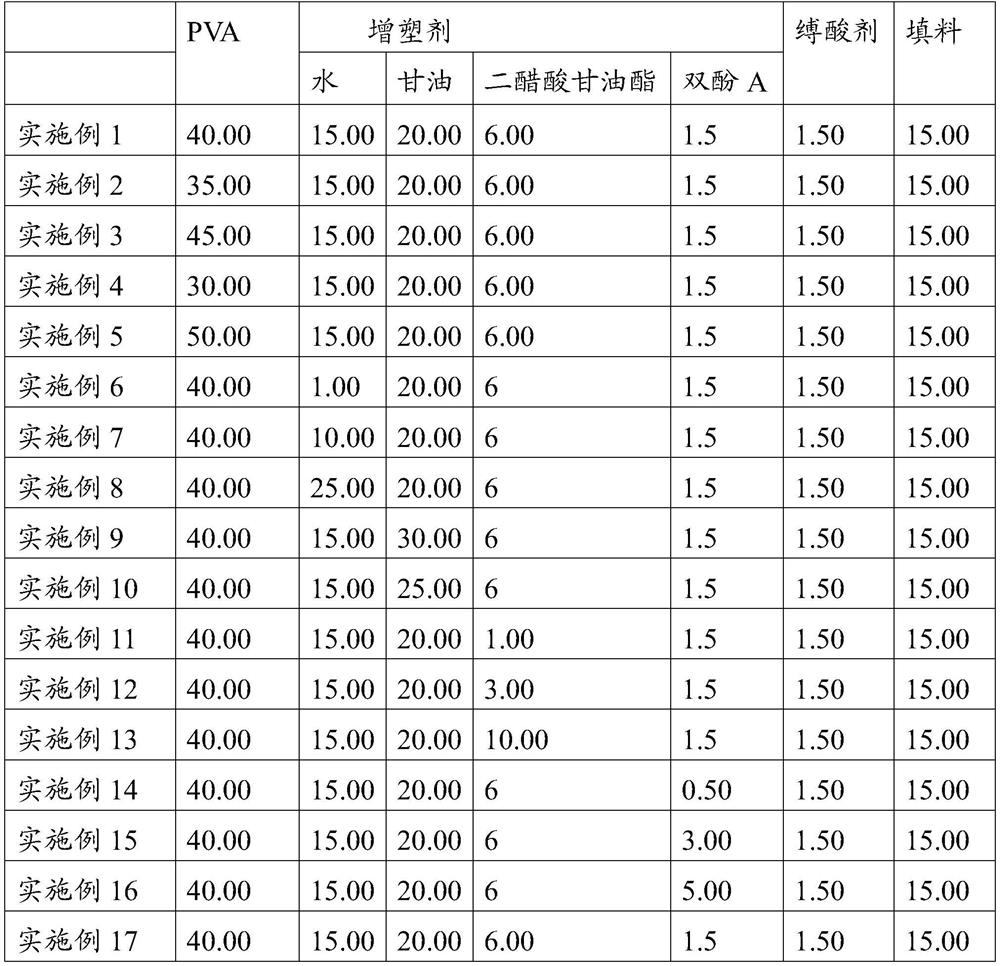

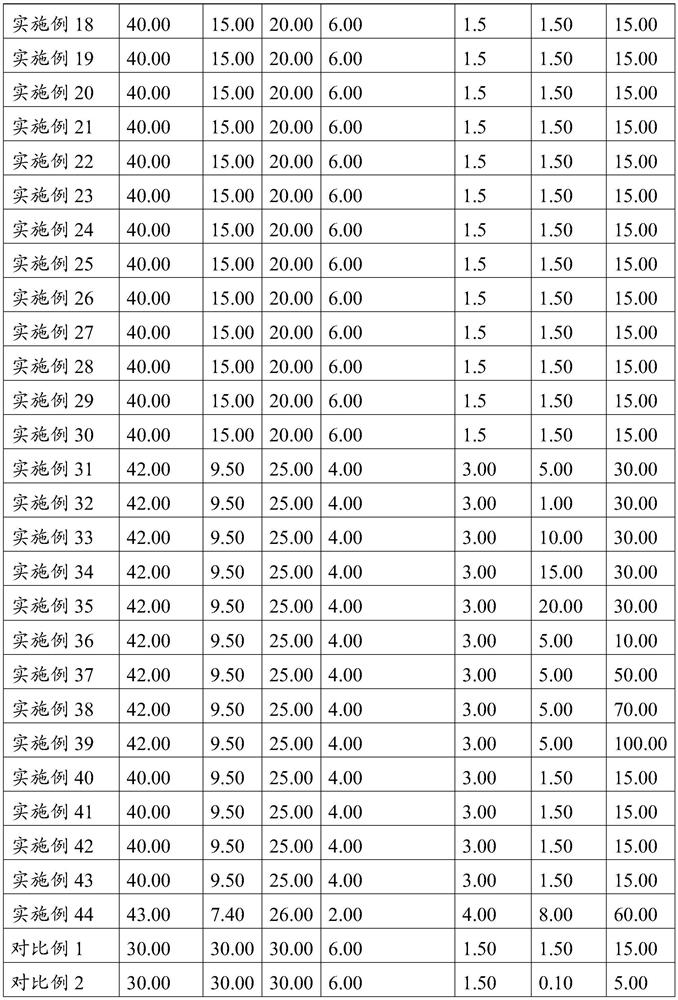

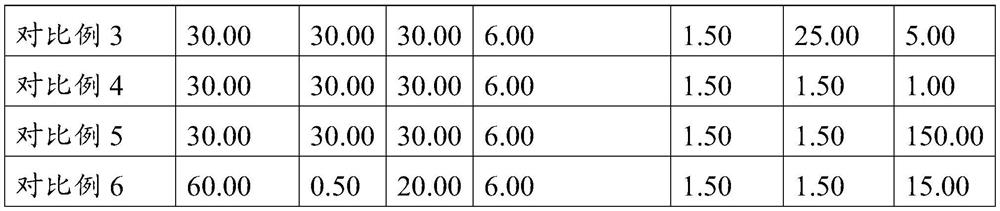

[0068] Mix the raw materials except water, and inject the obtained raw material mixture to obtain the rubber body, and then place the rubber body in an environment of 10-40 degrees Celsius and 30-100% humidity to absorb water for a predetermined time , to obtain a rubber cartridge, and the contents of each component in the obtained rubber cartridge are shown in Table 1.

[0069] Wherein, the degree of polymerization of the PVA resin is 2400, and the degree of alcoholysis is 98%; PVA resin / plasticizer=0.94:1; the acid-binding agent is sodium carbonate, and the filler is calcium carbonate.

Embodiment 2-16

[0071] Mix the raw materials except water, and inject the obtained raw material mixture to obtain the rubber body, and then place the rubber body in an environment of 10-40 degrees Celsius and 30-100% humidity to absorb water for a predetermined time , to obtain a rubber cartridge, and the contents of each component in the obtained rubber cartridge are shown in Table 1.

[0072] Wherein, the degree of polymerization of the PVA resin is 2400, and the degree of alcoholysis is 98%; the PVA resin / plasticizer is shown in Table 1; the acid-binding agent is sodium carbonate, and the filler is calcium carbonate.

Embodiment 17

[0074] Mix the raw materials except water, and inject the obtained raw material mixture to obtain the rubber body, and then place the rubber body in an environment of 10-40 degrees Celsius and 30-100% humidity to absorb water for a predetermined time , to obtain a rubber cartridge, and the contents of each component in the obtained rubber cartridge are shown in Table 1.

[0075] Wherein, the degree of polymerization of the PVA resin is 1200, and the degree of alcoholysis is 98%; PVA resin / plasticizer=0.94:1; the acid-binding agent is sodium carbonate, and the filler is calcium carbonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com