Pre-sealed foil pouch containing such as flavored tobacco for use with a hookah pipe and head attachment assembly

a foil pouch and hookah pipe technology, which is applied in the field of improved pre-packaged foil assembly, can solve the problems of uneven burn, incomplete, and fouling of tobacco, and achieve the effects of improving the quality of tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

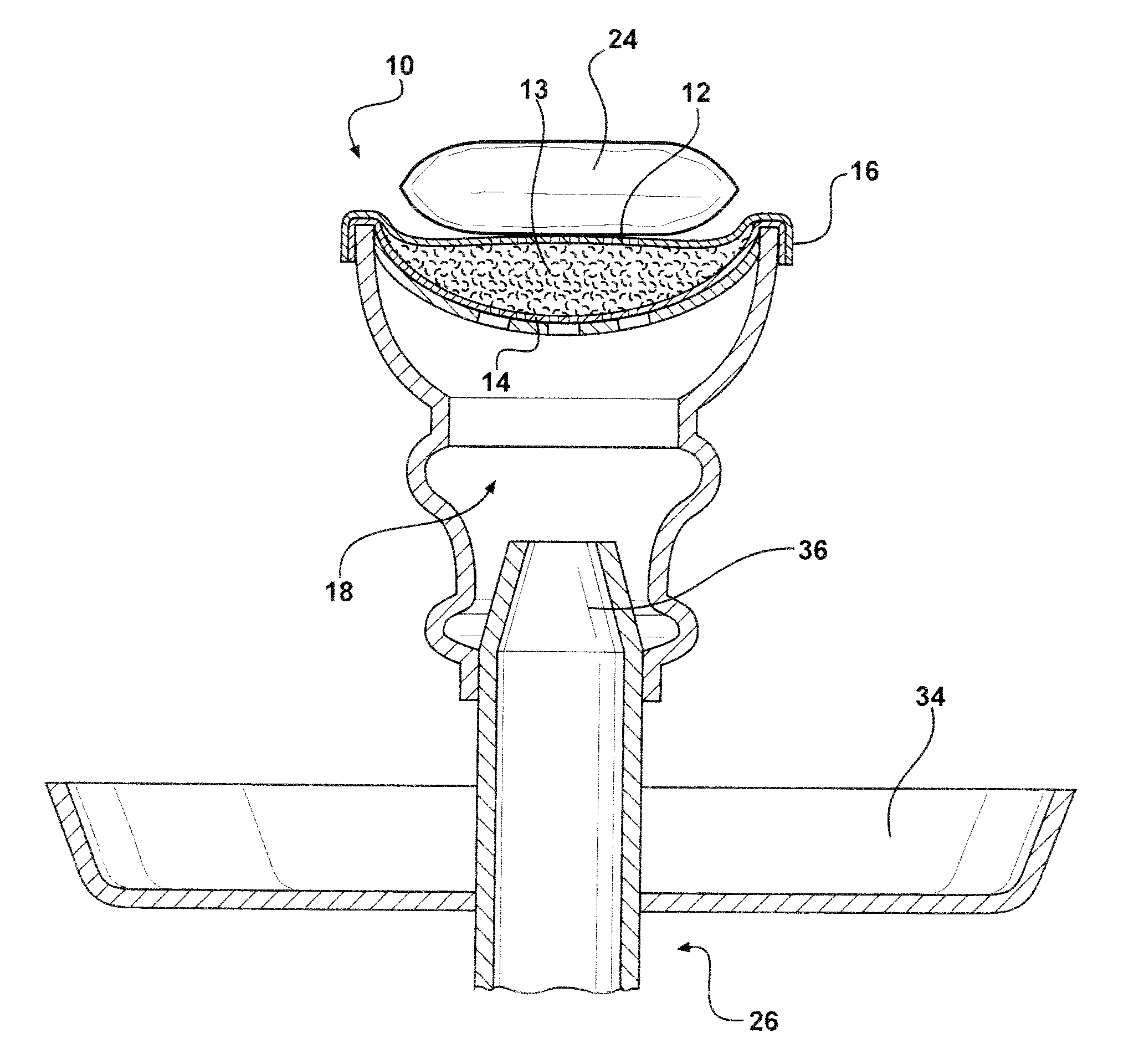

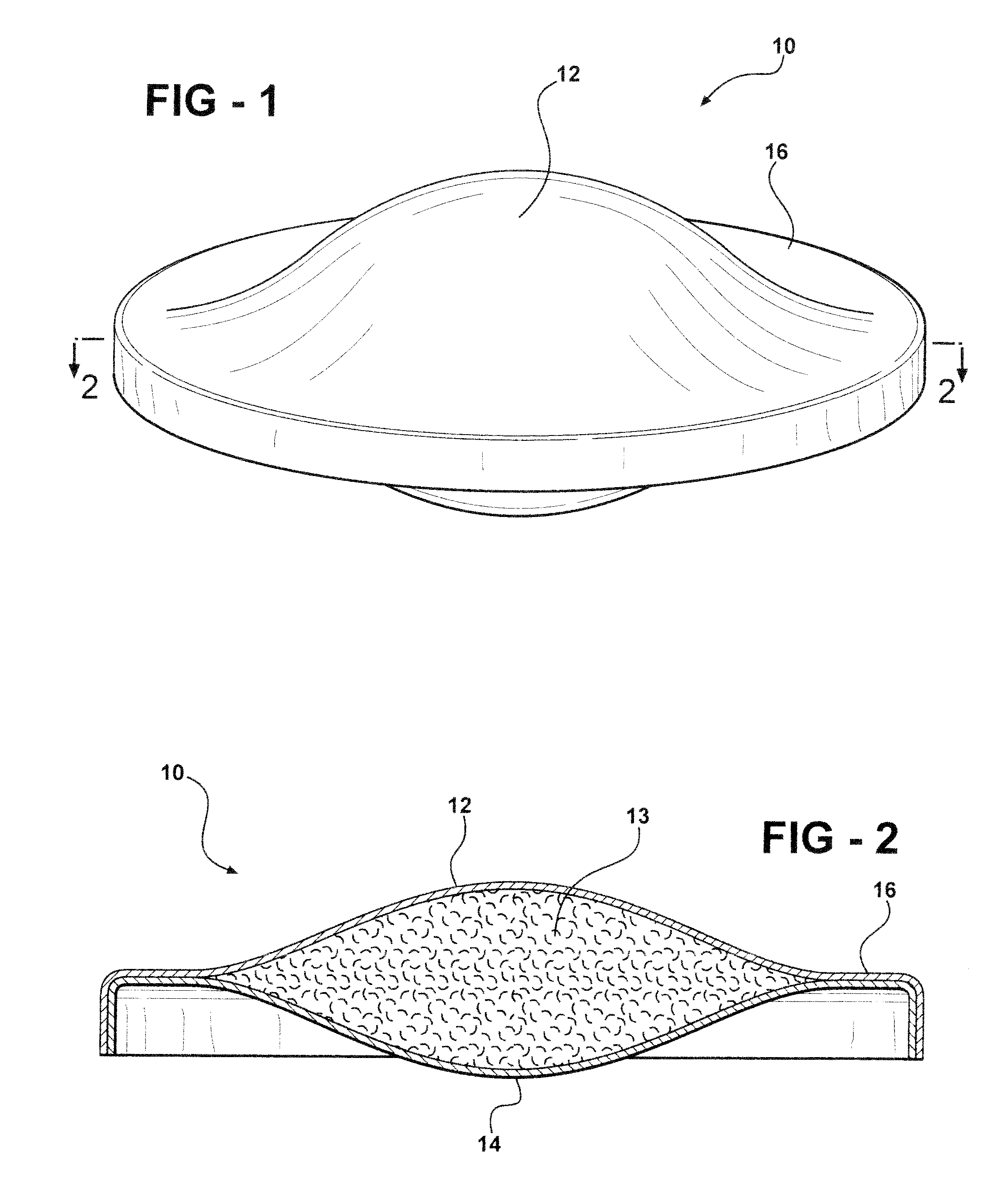

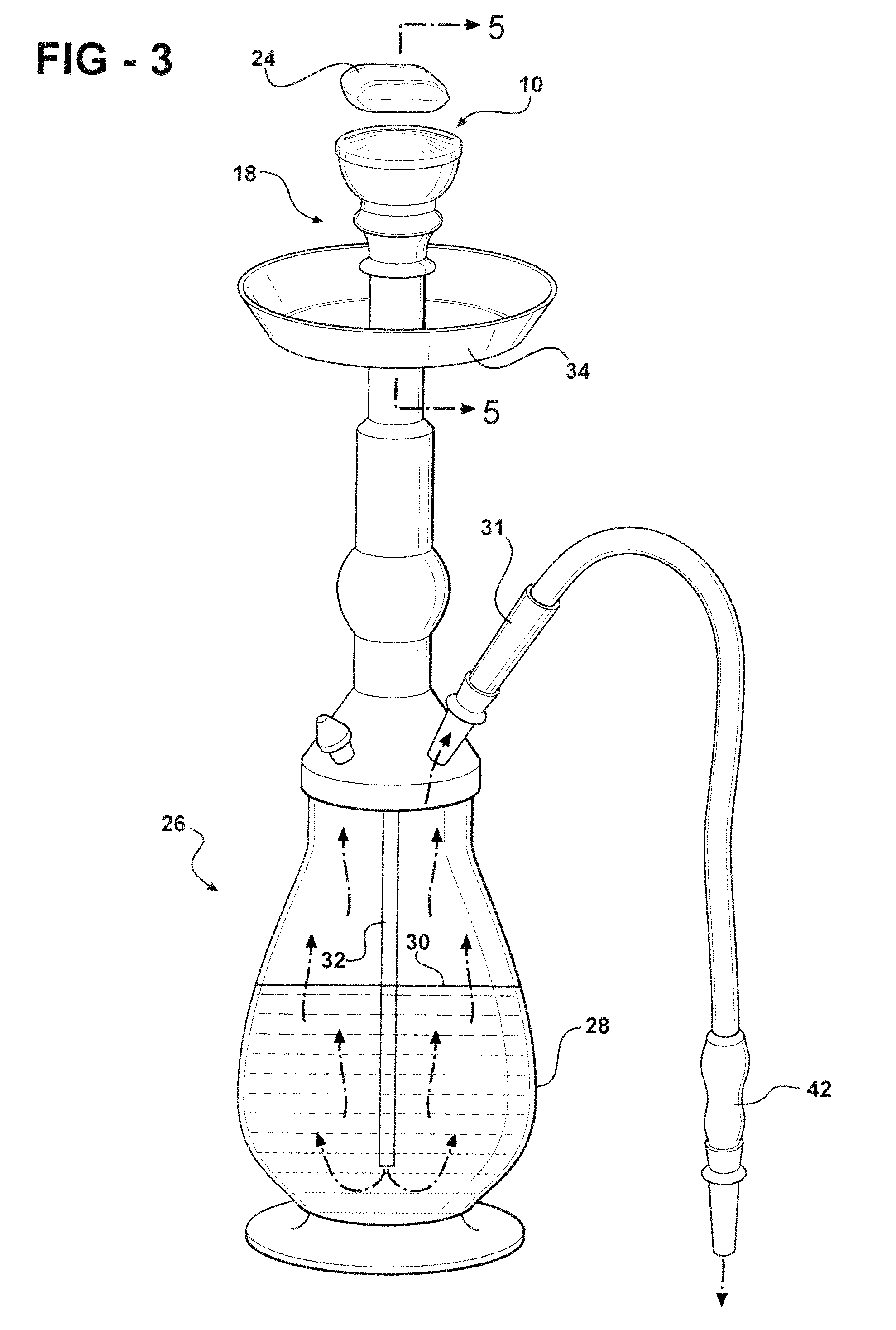

[0019] Referring now to FIGS. 1 and 2, an improve prepackaged / pre-sealed foil pouch construction is illustrated at 10, as will be explained as being utilized with such as a hookah / water pipe, and for containing a volume of a moisture laden tobacco, such as molasses or other flavored tobacco, see as further shown at 13 in each of FIGS. 2 and 5. The pouch construction in particular employs a dual layer (aluminum) foil, see upper layer 12 and lower perimeter connecting layer 14, collectively defining an annular extending lip or rim 16.

[0020] According to the known art, the most commonly used tobaccos (also known as tobamel or maassel) are produced according to a 1:2 ratio mixture of shredded tobacco leaf mixed with a sweetener such as honey, molasses, or semi-dried fruit. Due to the more recent popularity of flavored hookah tobaccos, manufacturers have begun to use glycerin as a primary sweetener given its humectant qualities and subtle sweetening properties that tend to accentuate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com