Fiber-reinforced composite member and method for producing structure using same

a composite member and fiber reinforcement technology, applied in the field of fiber reinforcement composite members, can solve the problems of high production cost, inability to achieve high efficiency, and inability to quickly determine the combination and position of the members to be connected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] [1] Fiber-Reinforced Composite Member

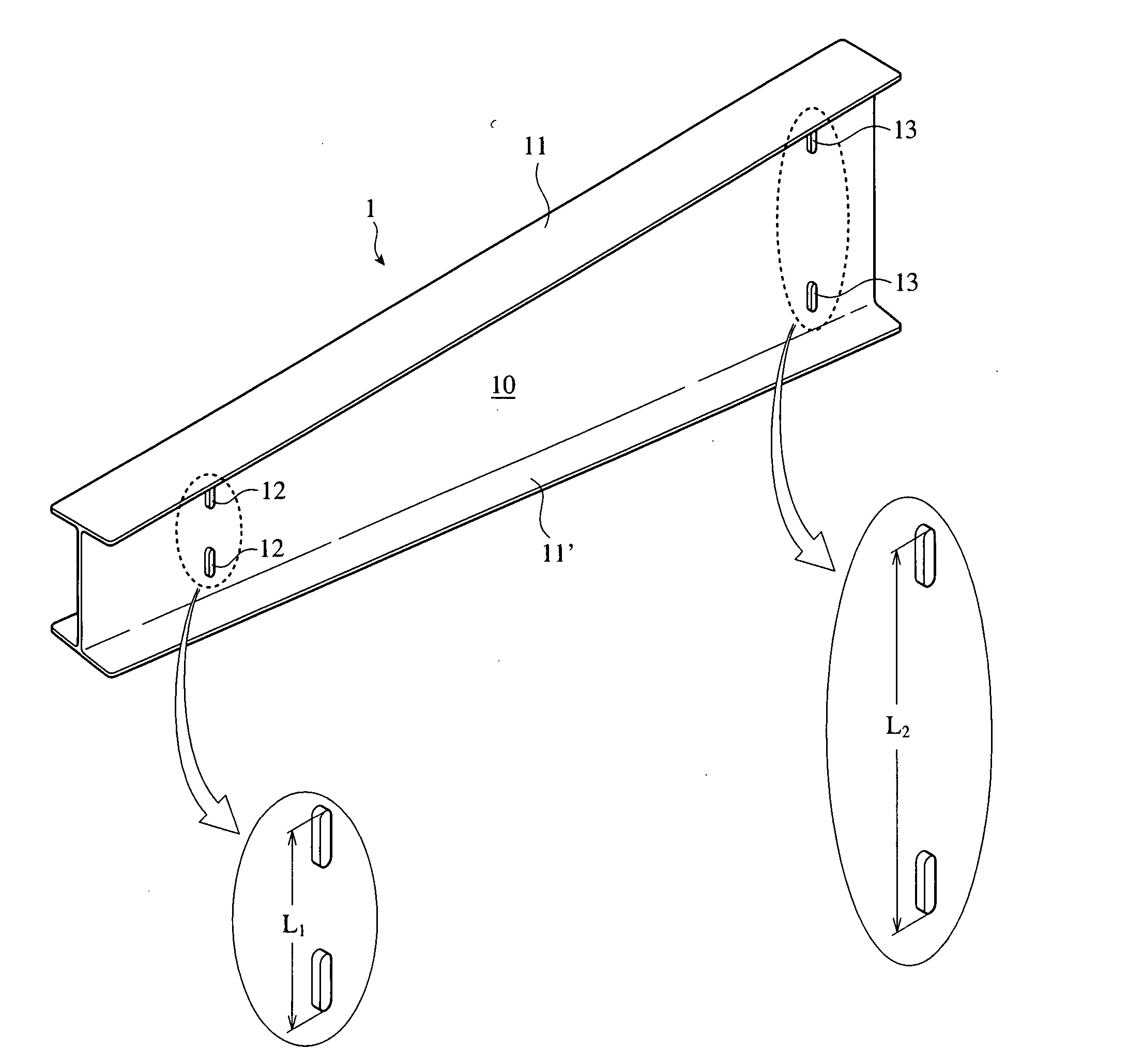

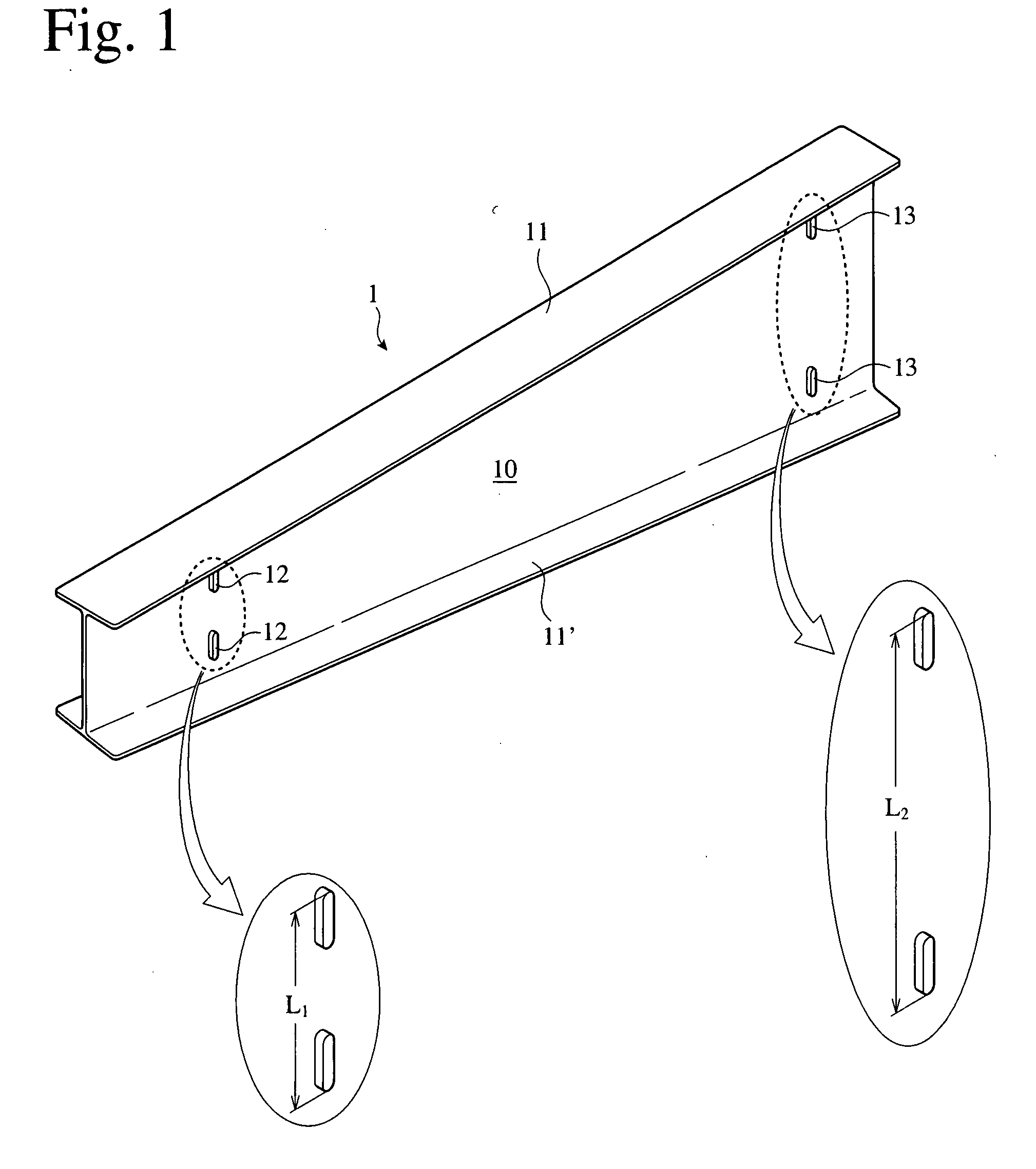

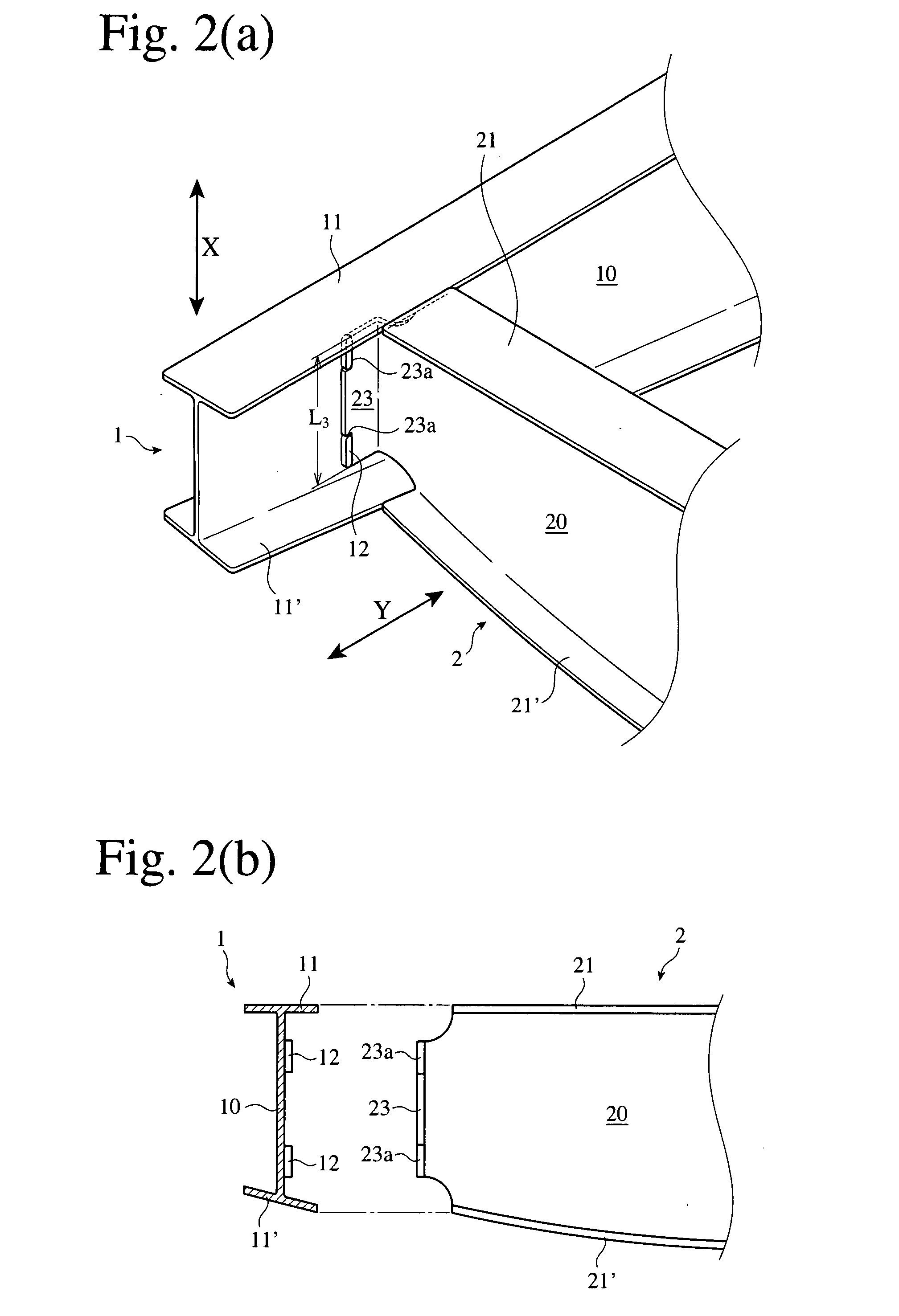

[0047]FIG. 1 shows a beam-shaped, fiber-reinforced composite member according to one embodiment of the present invention. This fiber-reinforced composite member 1, which is produced by curing prepregs of reinforcing fibers impregnated with a matrix resin, comprises a trapezoidal flat panel portion 10, flanges 11, 11′ extending from both side edges thereof toward both sides, and I-shaped, projections 12, 12, 13, 13 provided on both surfaces of the flat panel portion 10. One flange 11 vertically extends from the flat panel portion 10, while the other flange 11′ extends in a slanting direction relative to the flange 11. The projections 12 and 13 have information concerning the identification and predetermined connecting positions of said additional members to be connected to the fiber-reinforced composite member 1. In this embodiment, to identify the additional members, the distance L1 between the outer ends of the projections 12, 12 and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com