Step for temporary installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

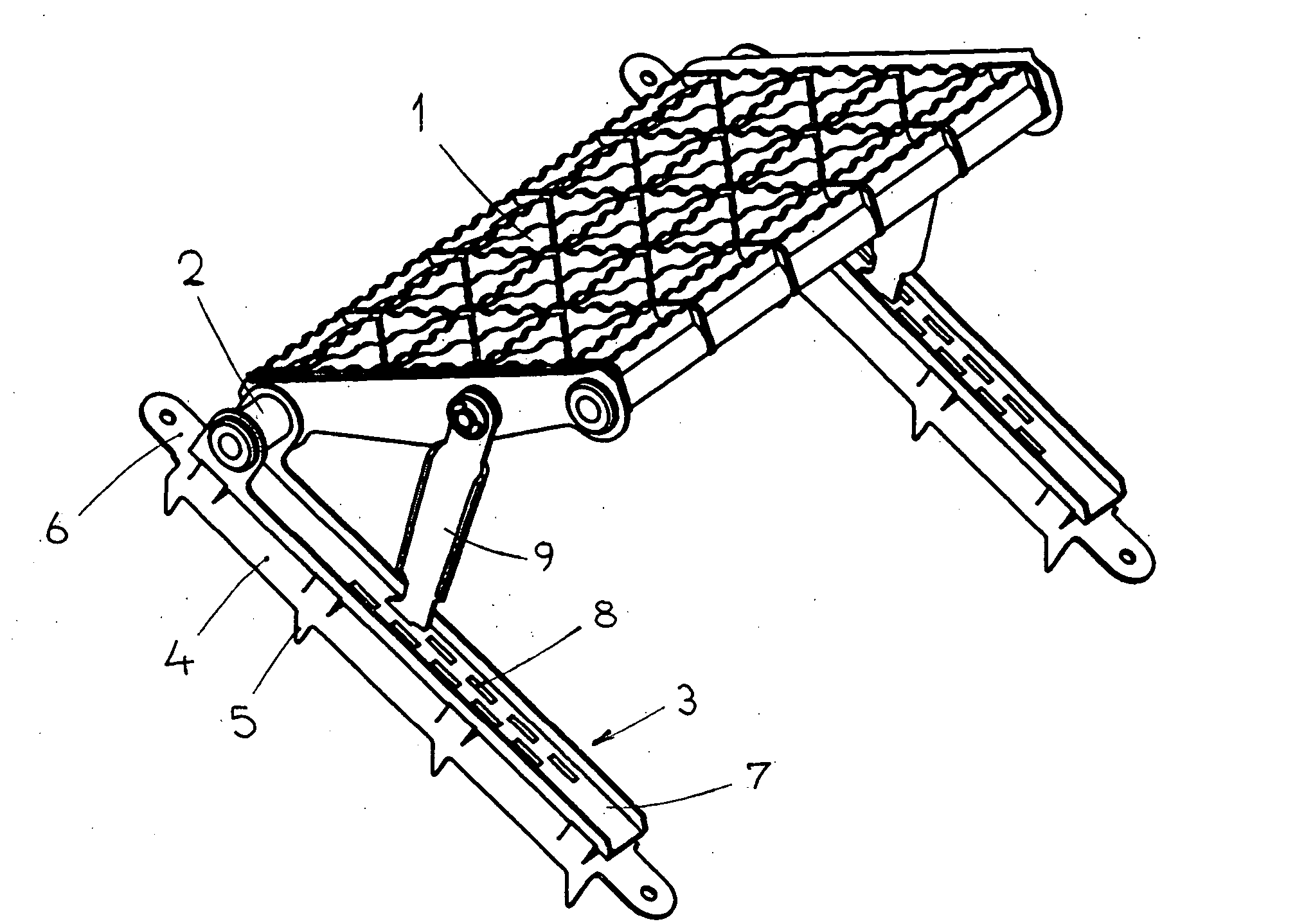

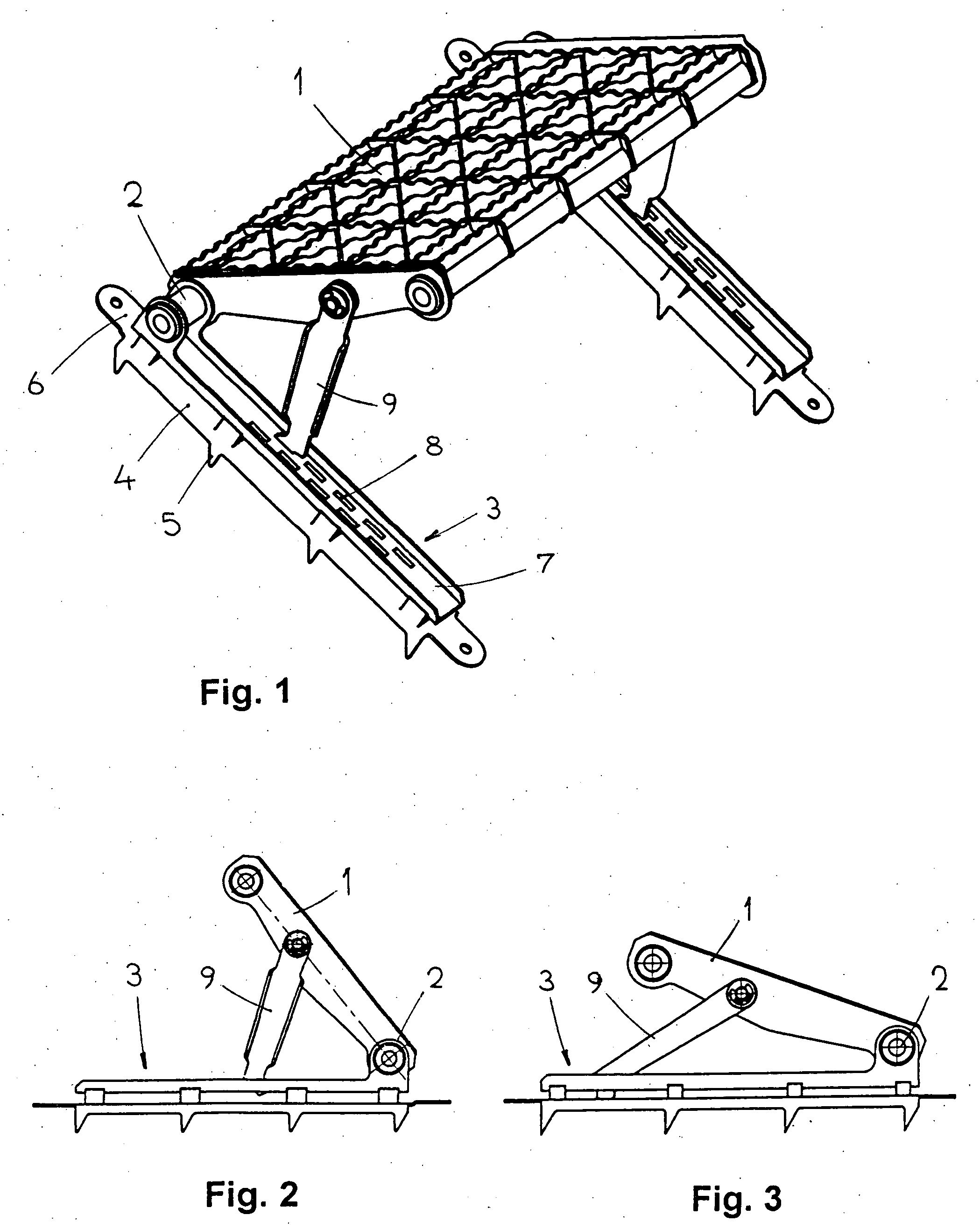

[0012]The step for temporary installation upon slopes consists of a step board 1 executed as a grid and provided laterally with pin joints 2 with horizontal axis at its rear side. Rails 3 consisting of two parts are pivoted to board 1 by way of pin joints 2 located outside of the step board 1. The bottom part 4 in form of U profile is provided with pins 5 at the bottom side for being driven into the ground and bears projections 6 with holes that serve for linking of adjacent steps, e.g. by nails driven into the ground. The elevated upper batten 7 bears a pin joint 2 and has two rows of offset holes 8. These holes serve for accepting the bottom end of strut 9 pivoted by its upper end at the side of step board 1.

[0013]The step can be installed upon a slope by driving the pins 5 of rails 3 into the ground, whereupon the bottom ends of struts 9 are inserted into holes 8 so as to ensure the horizontal position of board 1. It is obvious that this arrangement will enable, by suitable choic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com