Paper machine clothing with auxetic fibers and/or yarns

a technology of auxetic fibers and/or yarns, applied in the field of clothing, can solve the problems of affecting the performance and subsequent life of the press fabric, the quality of the paper sheet, and the bath fiber is exposed to “pulling” or tension forces, and achieves the effect of higher tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

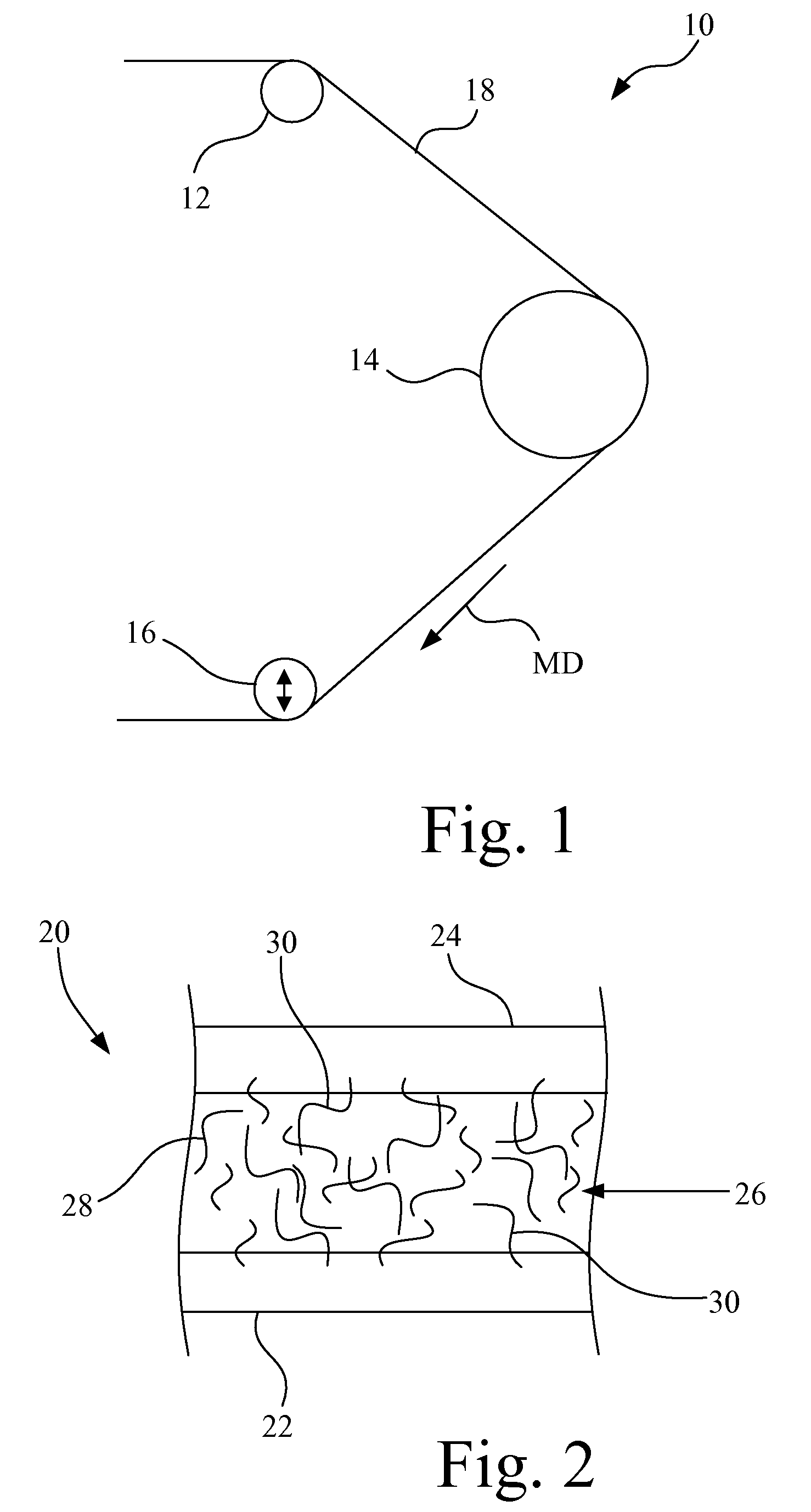

[0020]Referring now to the drawings, and more particularly to FIG. 1, there is shown an embodiment of a paper machine 10 of the present invention, which generally includes rolls 12, 14 and 16 which carry a paper machine clothing 18. Roll 16 is a tension roll which is adjustable as indicated by the double-headed arrow to provide a desired degree of tension on clothing 18. Clothing 18 may be differently configured, depending upon the type of fiber web being produced and the location of clothing 18 along the length of the paper machine, as will be more apparent from the description hereinafter.

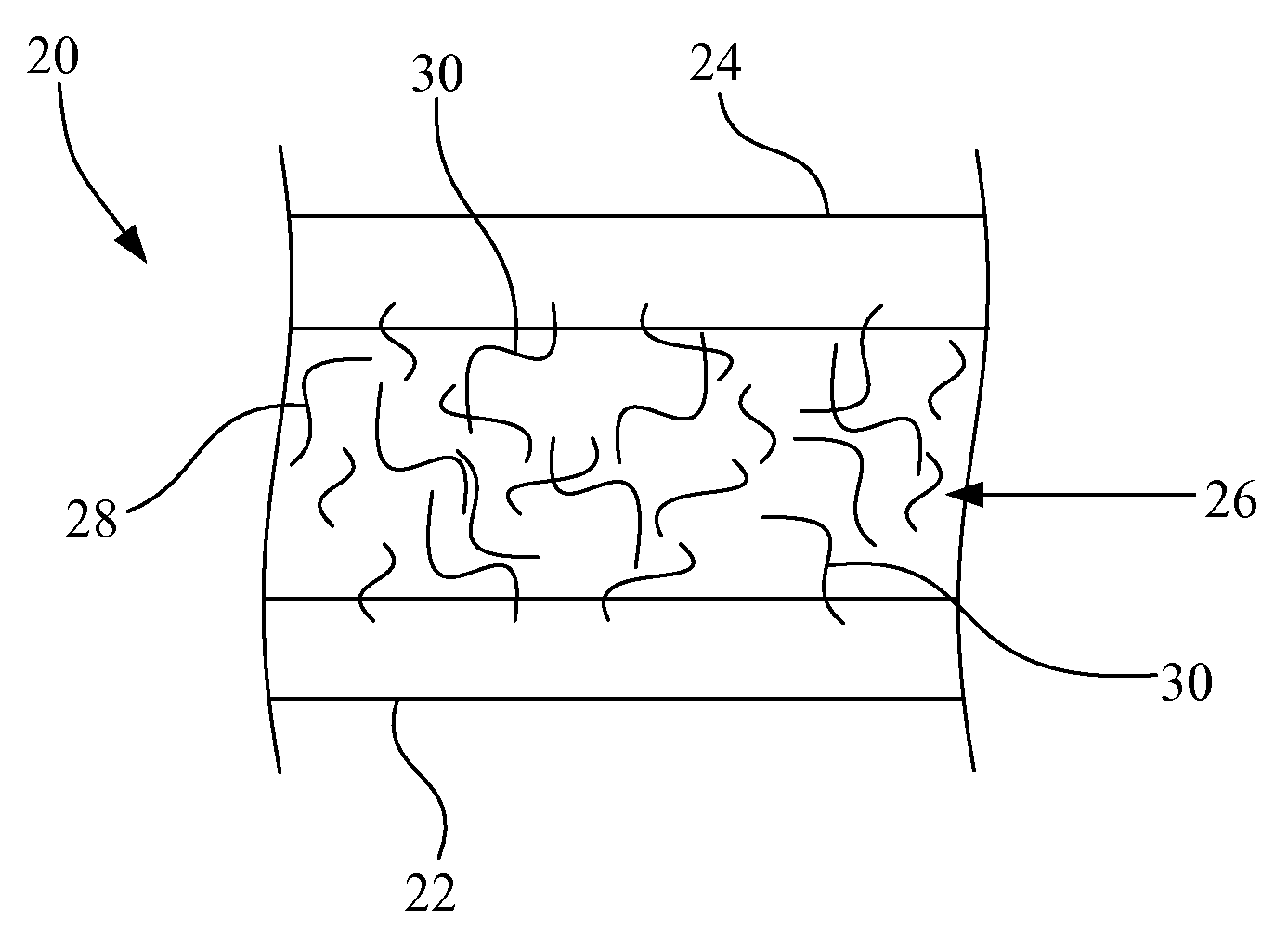

[0021]Referring to FIG. 2, a clothing in the form of a press fabric 20 will be described in greater detail. Press fabric 20 generally includes a first base layer 22, a second base layer 24 and batt fiber 26 which is physically and / or chemically coupled, e.g., via needling with at least one of first base layer 22 and second base layer 24. With a conventional press fabric 20, batt fiber 26 includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com