Tampon Applicator Assembly

a technology of applicator and assembly, which is applied in the field of tampon applicator assembly, can solve the problems of assembly with displaced tampons that cannot be used and need to be discarded, consumer annoyance, and displacement of tampons, so as to reduce the total amount of contact, reduce the overall friction, and advantageously minimize the likelihood of tampon displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

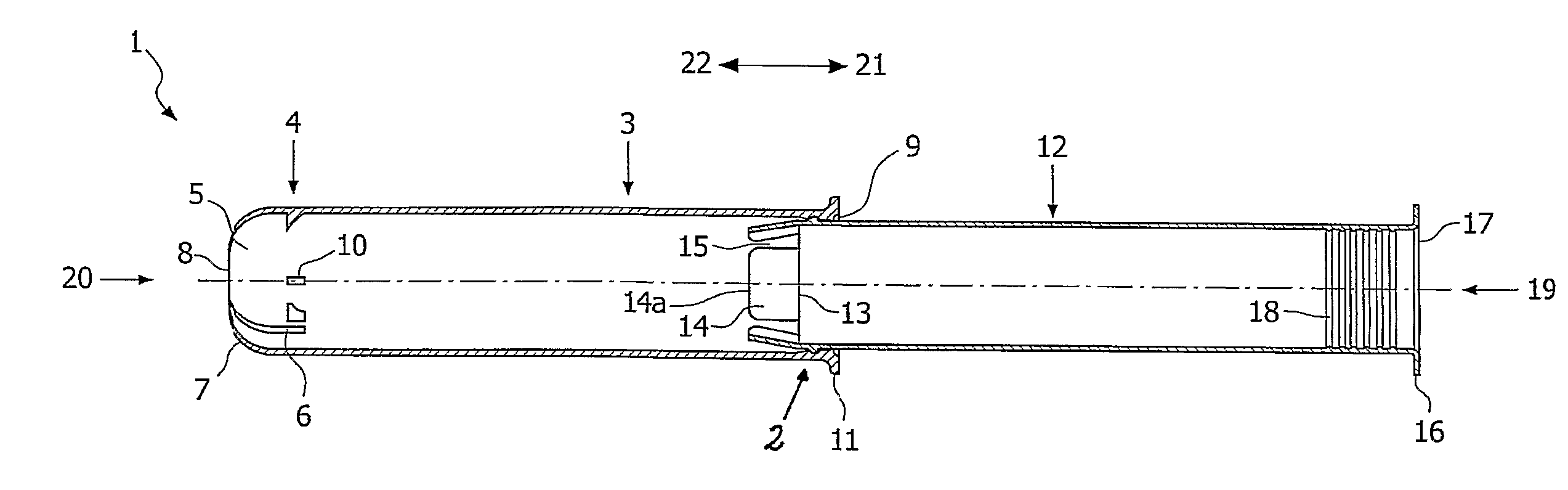

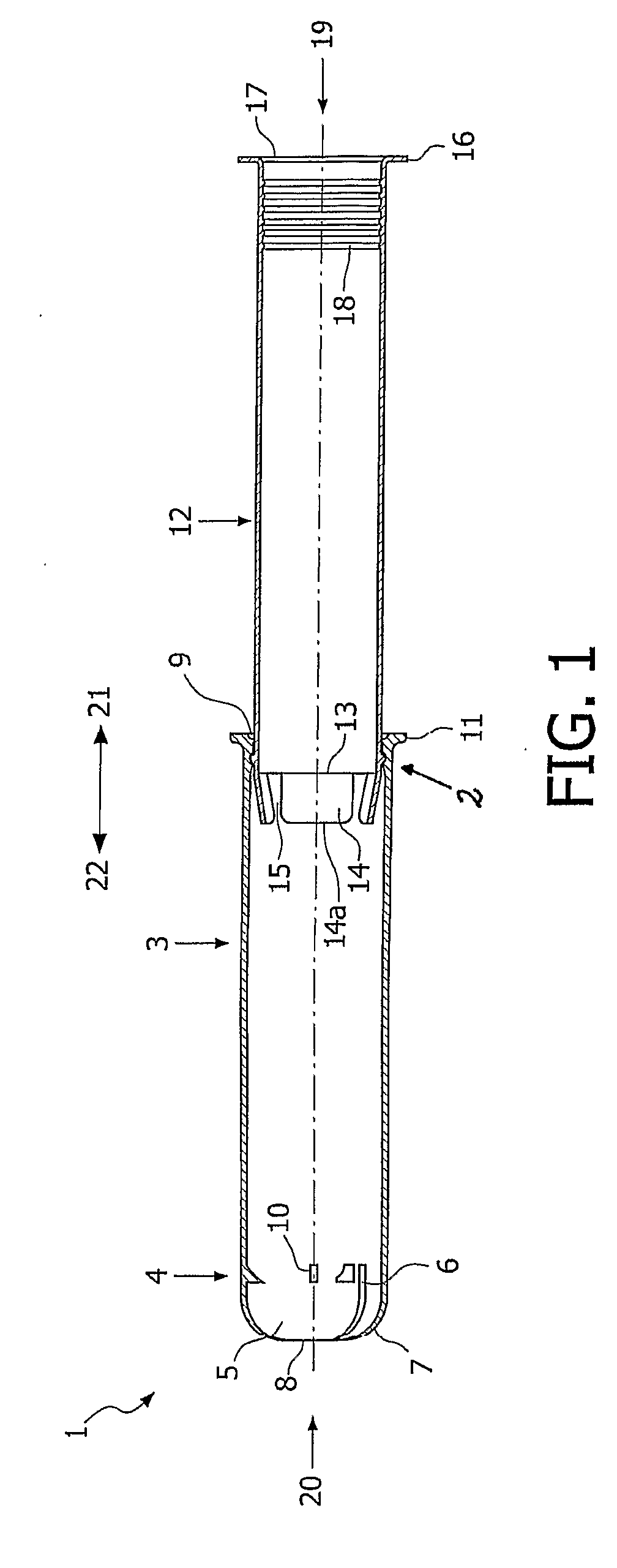

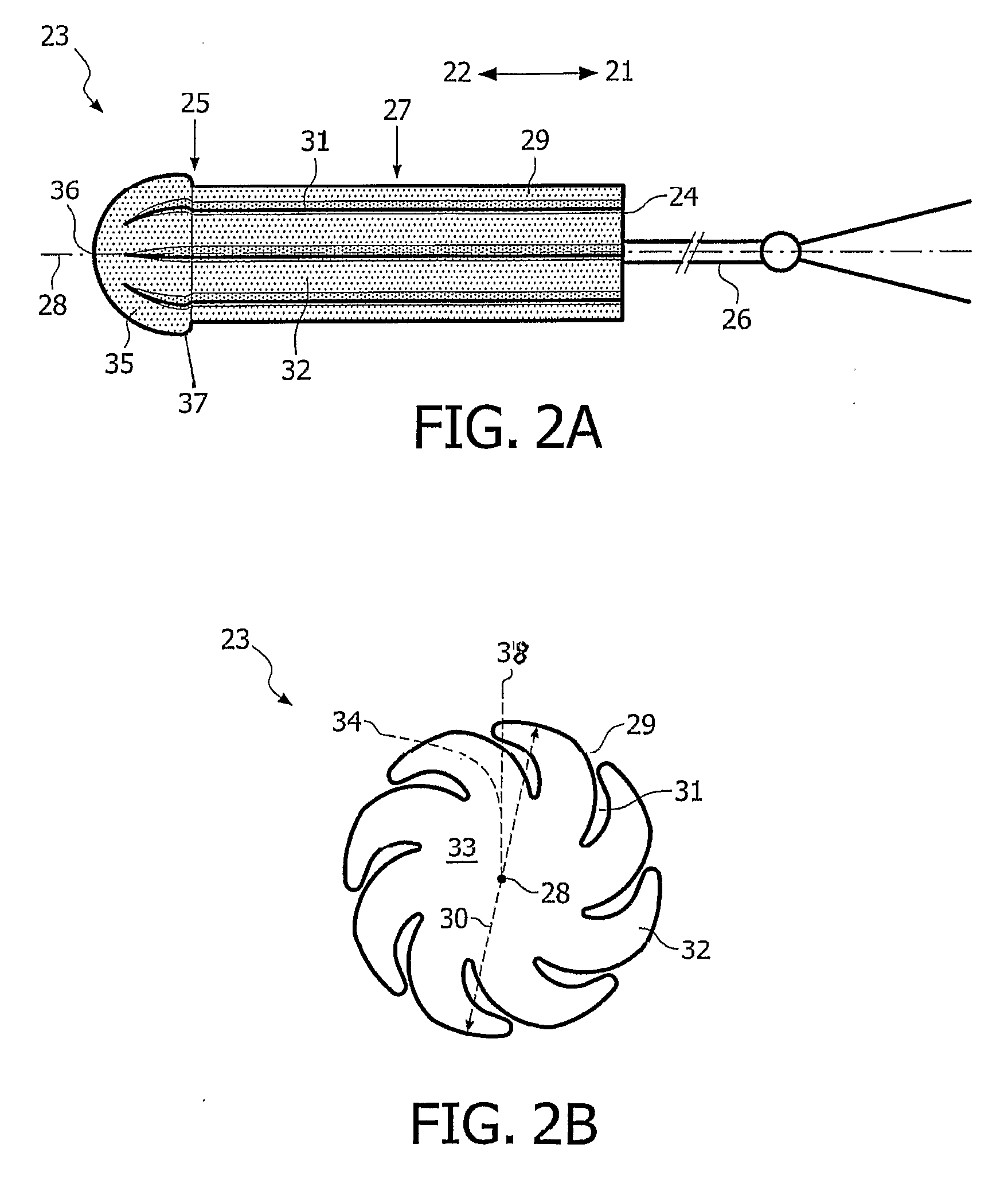

[0017]The invention is further explained with reference to FIGS. 1 to 4, which illustrate preferred, but non-limiting embodiments of the present assembly and of its parts, i.e., a compact tampon applicator 1 and a tampon 23.

[0018]The present assembly defines a proximal end 19 and a distal end 20. As used herein, the term “proximal end”19 refers to those portions of the assembly and of its parts that are most remote from the body of a user when the tampon 23 is being emplaced within a body cavity, e.g., a vaginal cavity. The term “distal end”20 refers to those portions of the assembly and of its parts that are closest to the body of a user when the tampon is being emplaced. Accordingly, the terms “proximal” or “proximally”, and “distal” or “distally”, as used herein, specify that a given portion or structure of the assembly or of its parts is relatively closer to, respectively, the proximal end 19 or the distal end 20 of the assembly or of its parts. Similarly, the terms “proximal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com