Fire sprinkler head paint cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

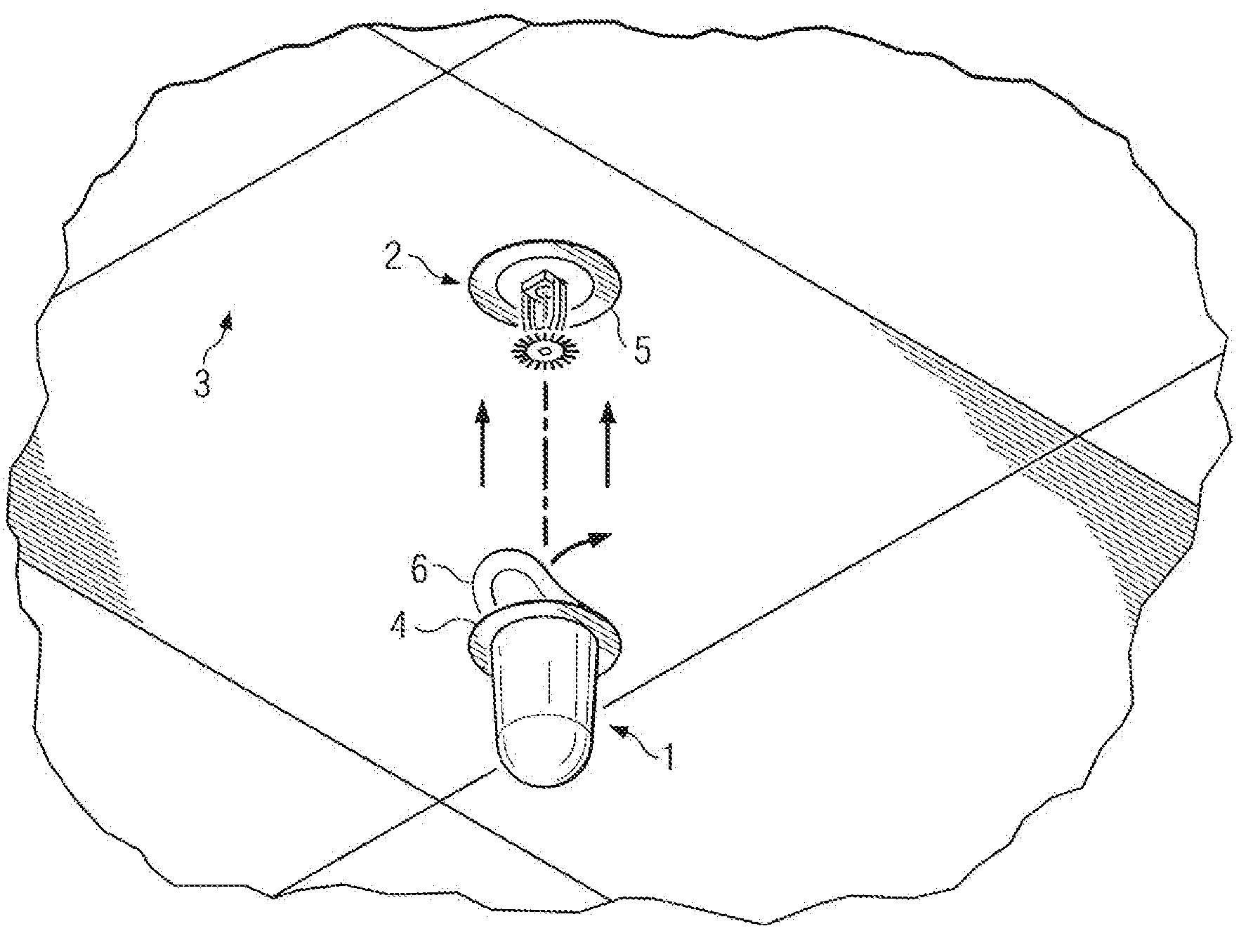

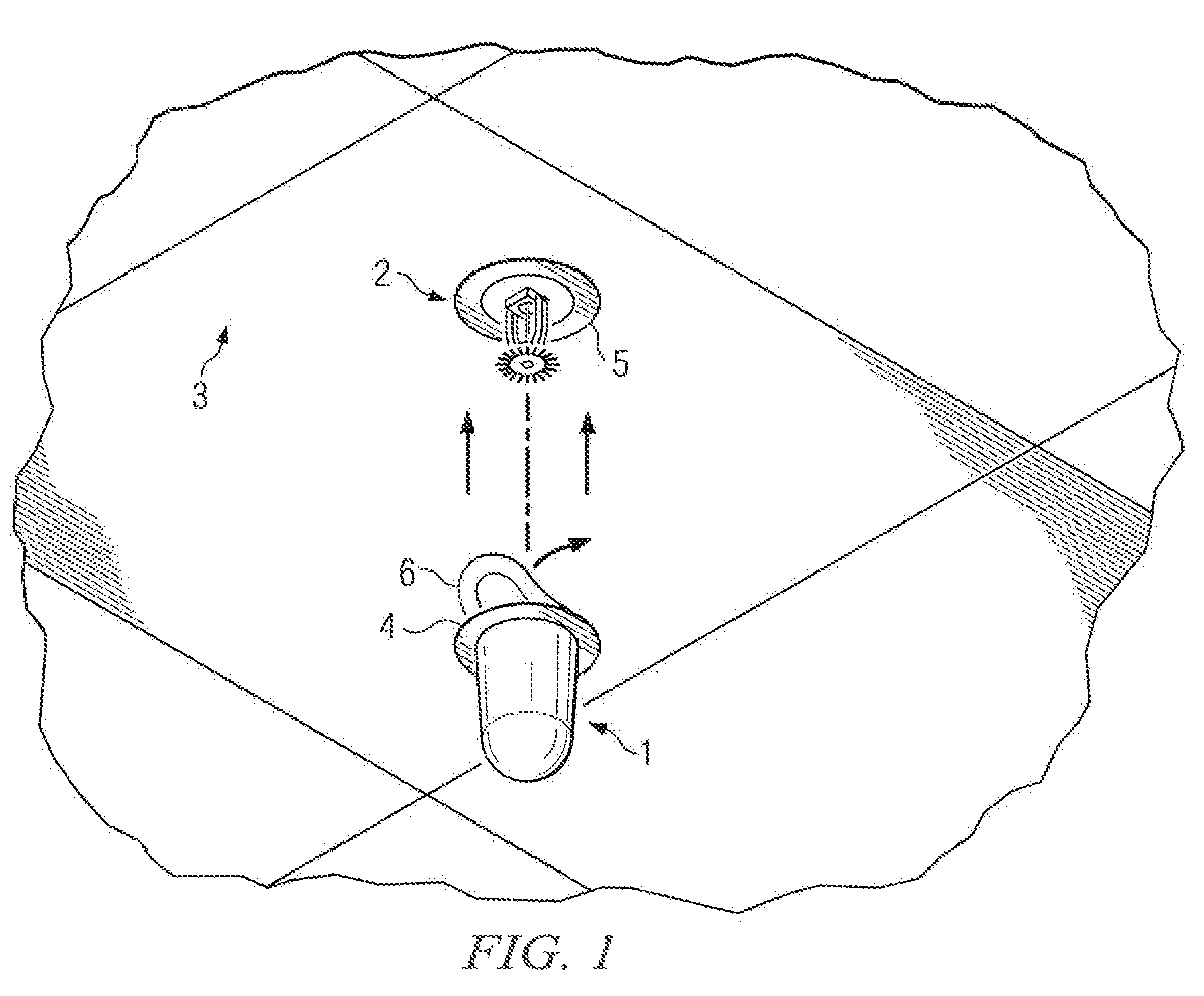

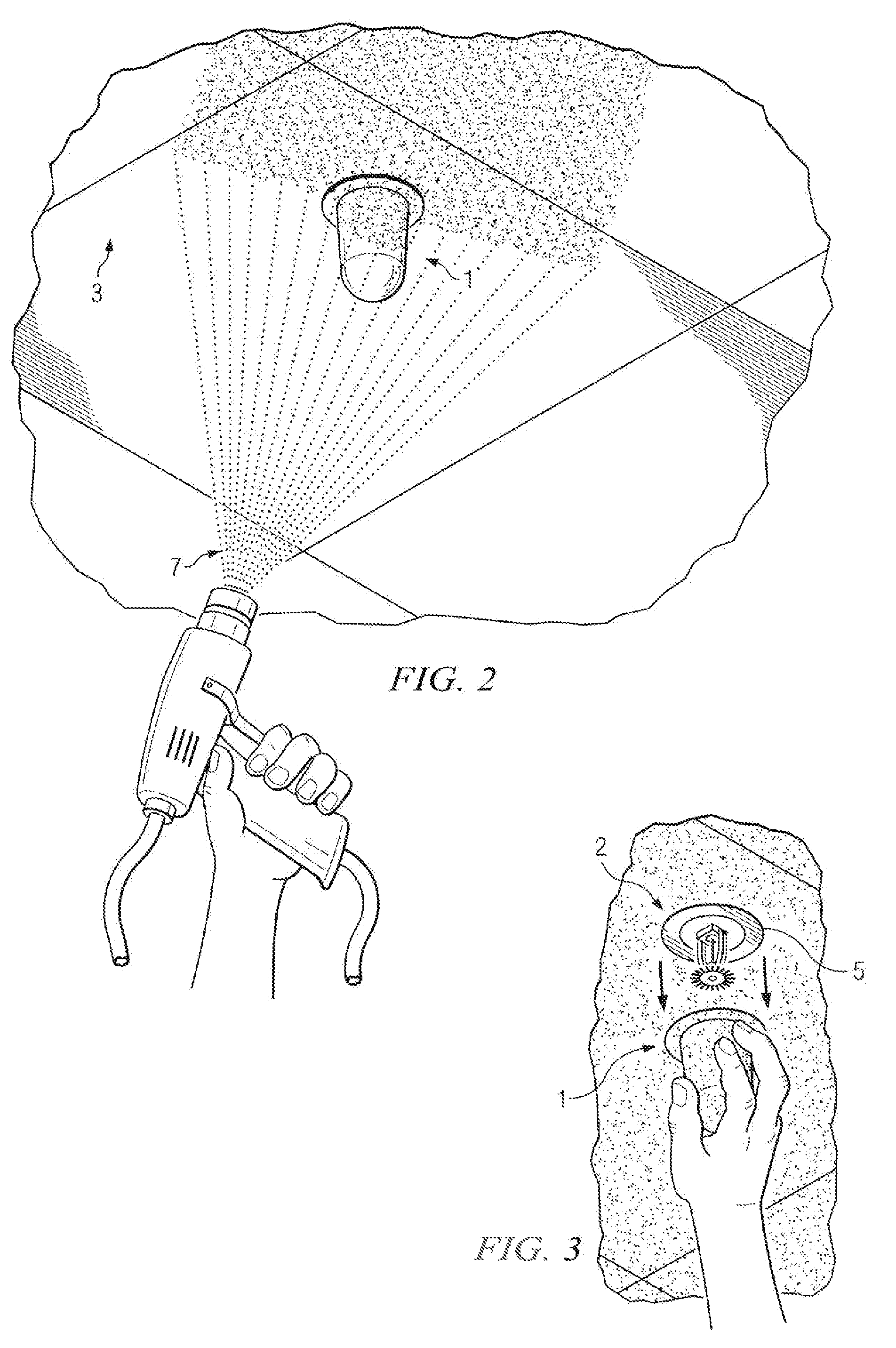

[0013]Referring to the drawings, and particularly to FIG. 1 thereof, a fire sprinkler head paint cover 1 comprising the present invention is illustrated. The fire sprinkler head paint cover 1 is configured so as to allow its application or placement over a fire sprinkler head 2 of an automatic fire sprinkler system. Here, the fire sprinkler head 2 is installed in a surface comprising a ceiling 3 it being understood that fire sprinkler heads are also installed in walls and other surfaces.

[0014]In the embodiment shown, the fire sprinkler head paint cover 1 is cylindrical or conical in shape, however, it is envisioned that the fire sprinkler head paint cover 1 can be of any shape and / or size conceivable, thereby enabling it to be placed over variously shaped fire sprinkler heads and / or fire sprinkler heads with different configurations. The fire sprinkler head paint cover 1 can be constructed of plastic or any other suitable material as desired, so long as the material is of proper wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com