Burping projectile

a projectile and projectile body technology, applied in the field of burping projectiles, can solve the problems of reduced recoil impulse, reduced recoil impulse, and reduced kinetic energy of projectile body upon impact to penetrate the target and harm surrounding human assets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

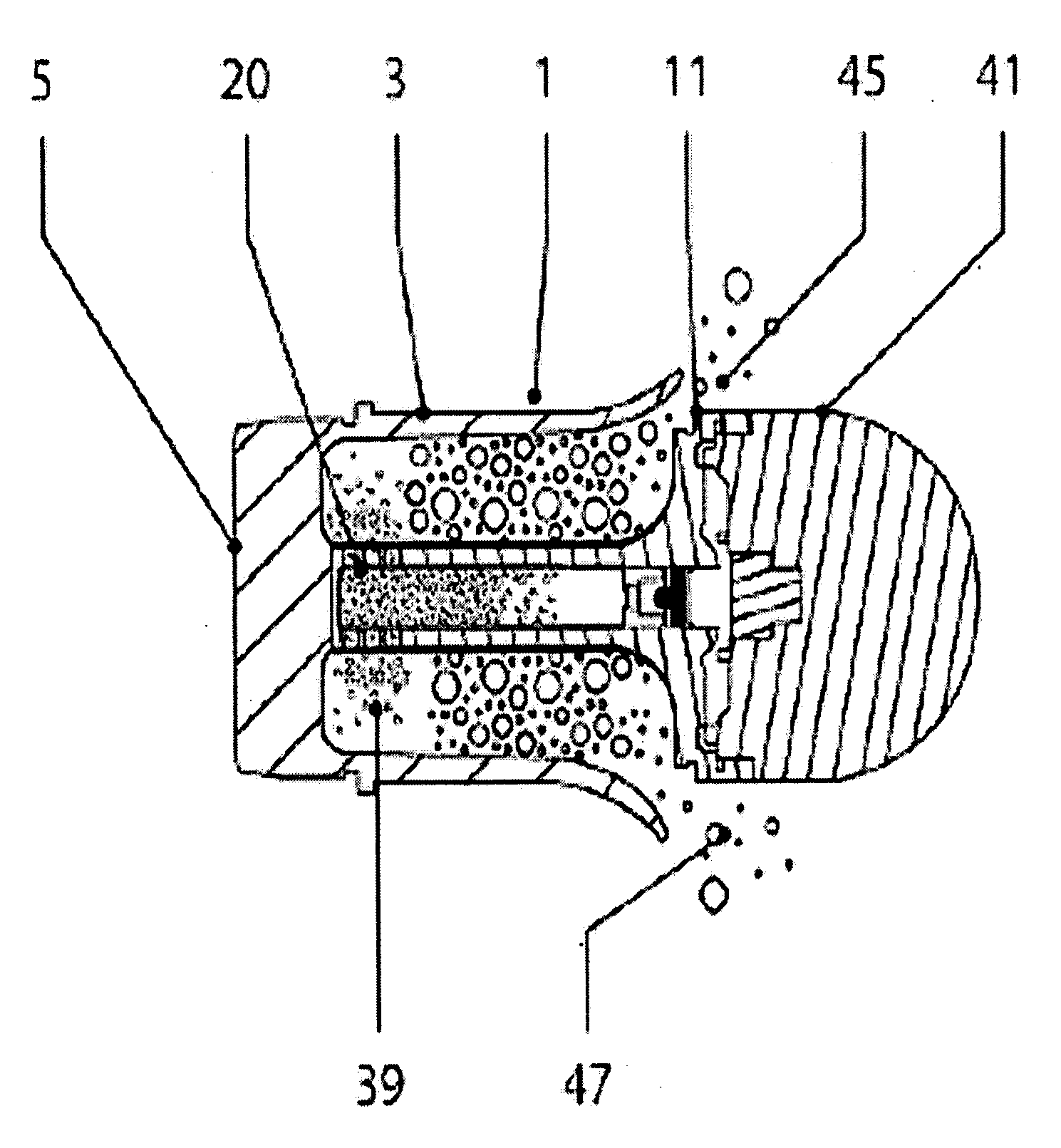

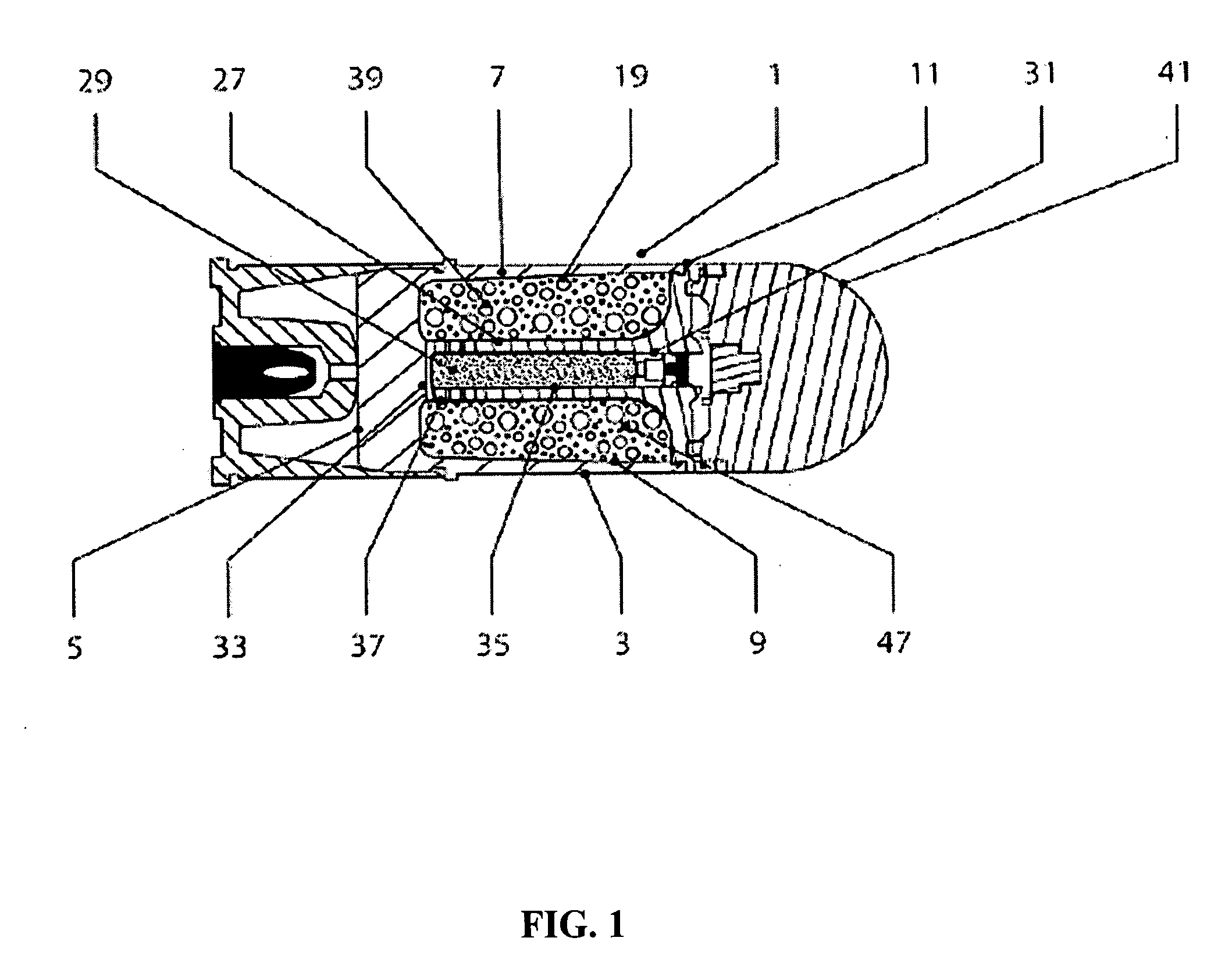

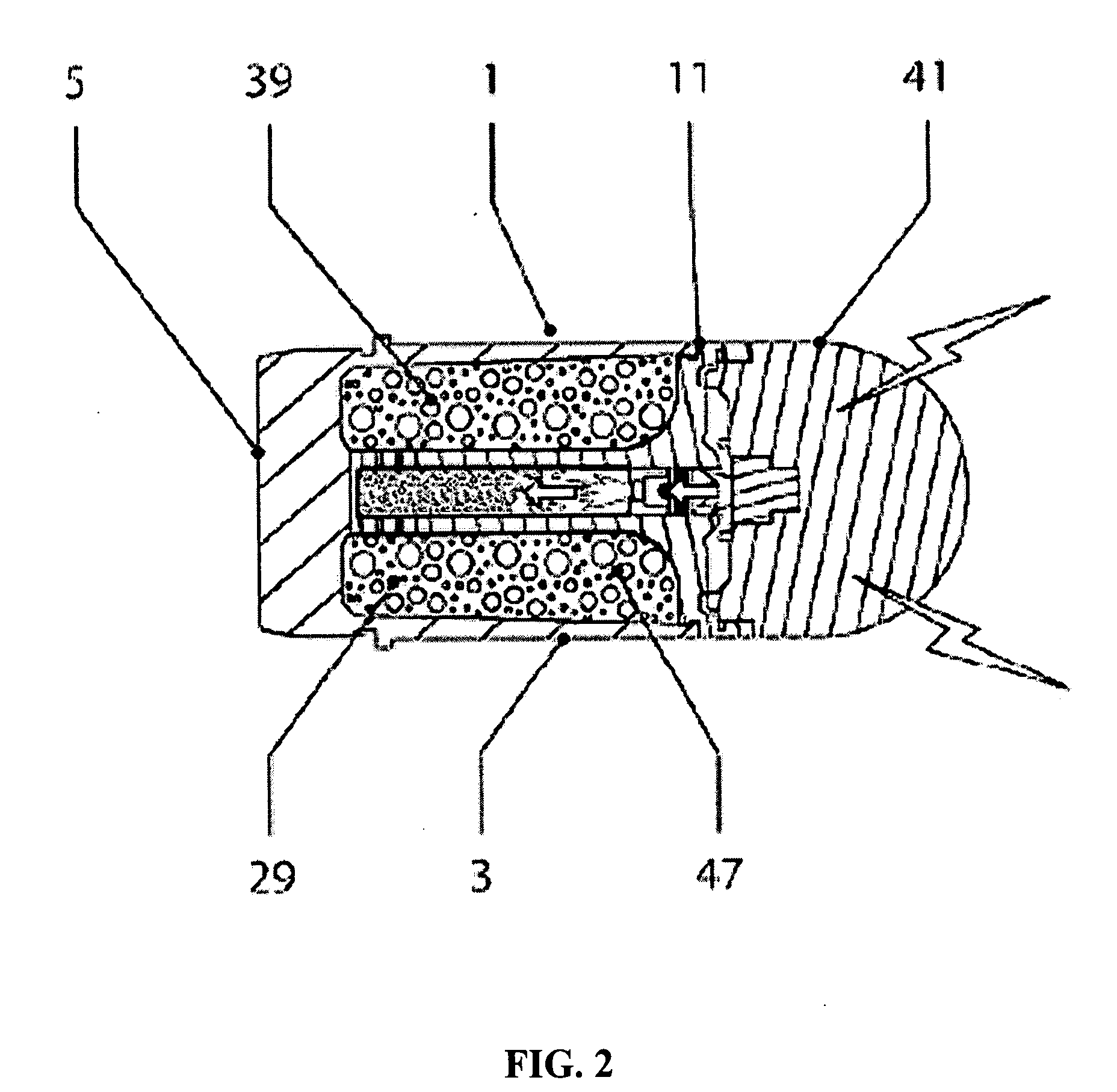

[0055]As illustrated in FIG. 1 herein, the present invention provides a burping projectile 1, shown as part of a grenade before firing thereof. The burping projectile 1 is comprised of a hollow projectile body 3 having a rear end 5, a circumferential portion 7 adjacent the rear end 5 defining an interior portion 9, and a front edge 11 opposite the rear end 5 defined by the circumferential portion 7. The hollow projectile body 3 is formed of metals or polymers that are able to slightly expand without extreme fragmenting upon exposure to high pressures and temperatures. Generally, aluminum, copper, brass or steel are used, with aluminum being the most preferred material, based on ease of manufacture, high strength to weight ratio, sufficient elongation properties and, in flash-bang applications, the contribution of the aluminum to the flash-bang reaction.

[0056]It has been found that the optimum thickness of the circumferential portion 7 of the hollow projectile body 3, when formed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com