Foam pad with cork layer

a foam pad and cork technology, applied in the field of foam pads with cork layers, can solve the problems of poor flexibility of foam pads made by eva, pvc, tpe or poe, and the surface of foam pads that are slippery and the user might fall, and achieve good ventilation and sweat absorption. , the effect of satisfying the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

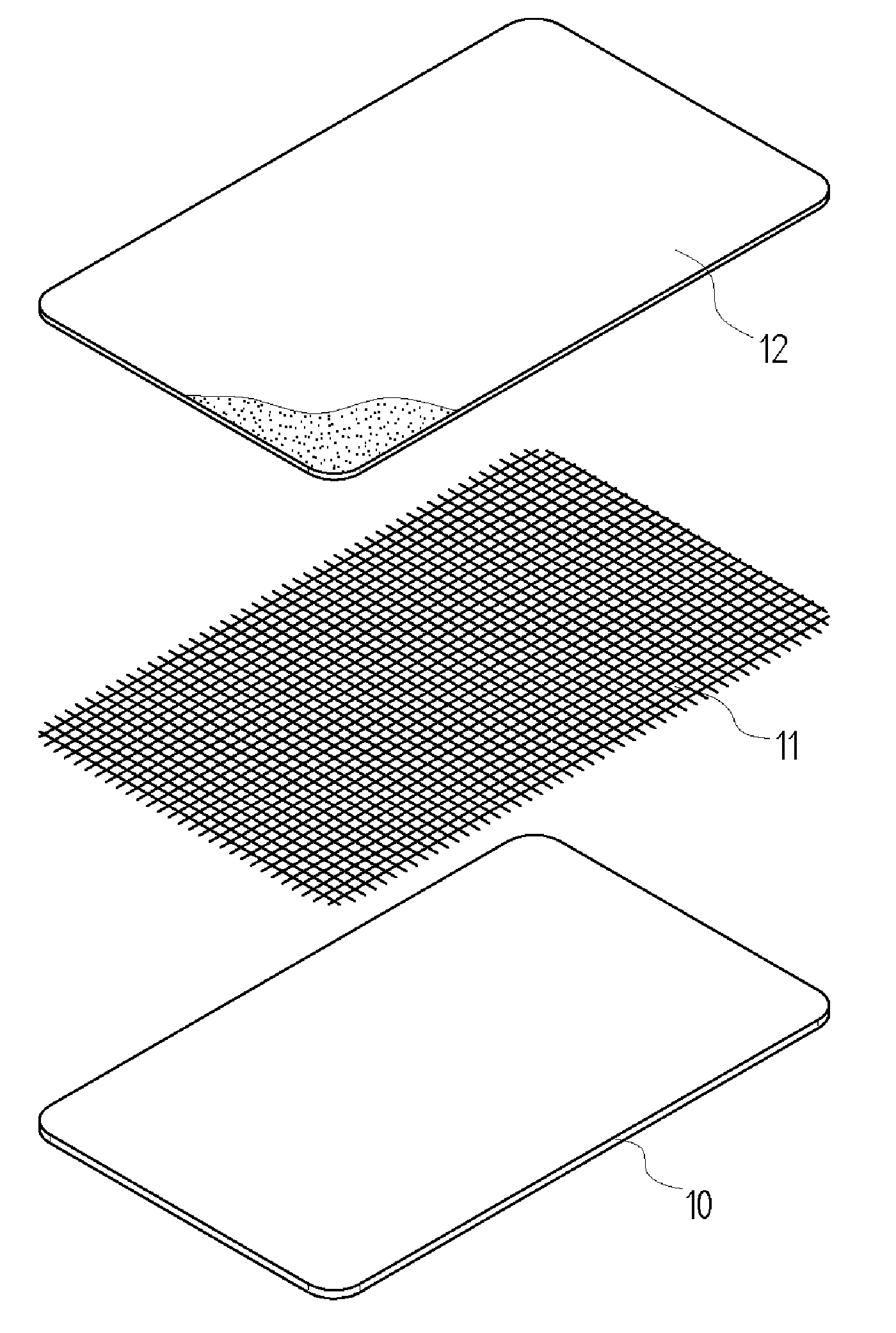

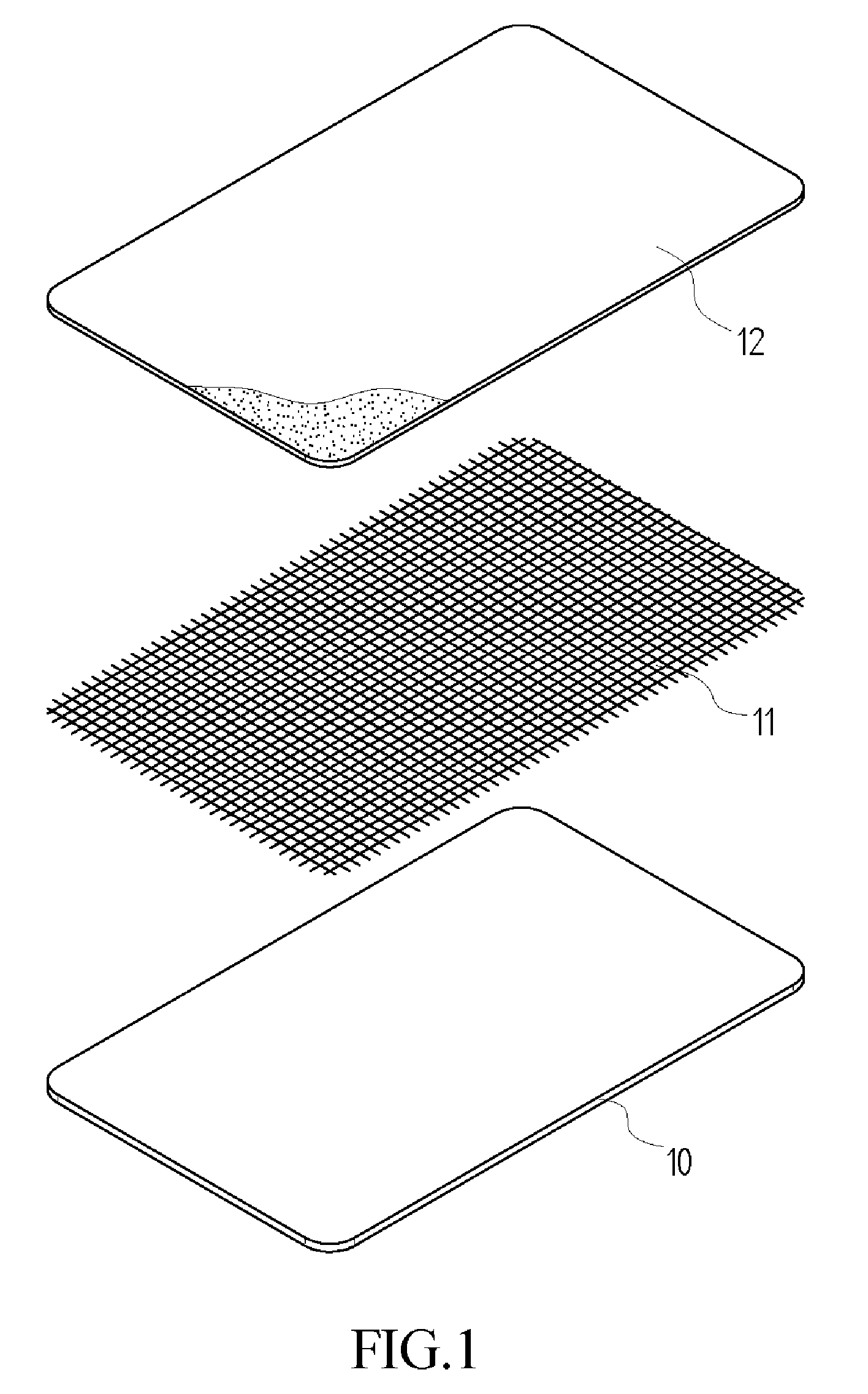

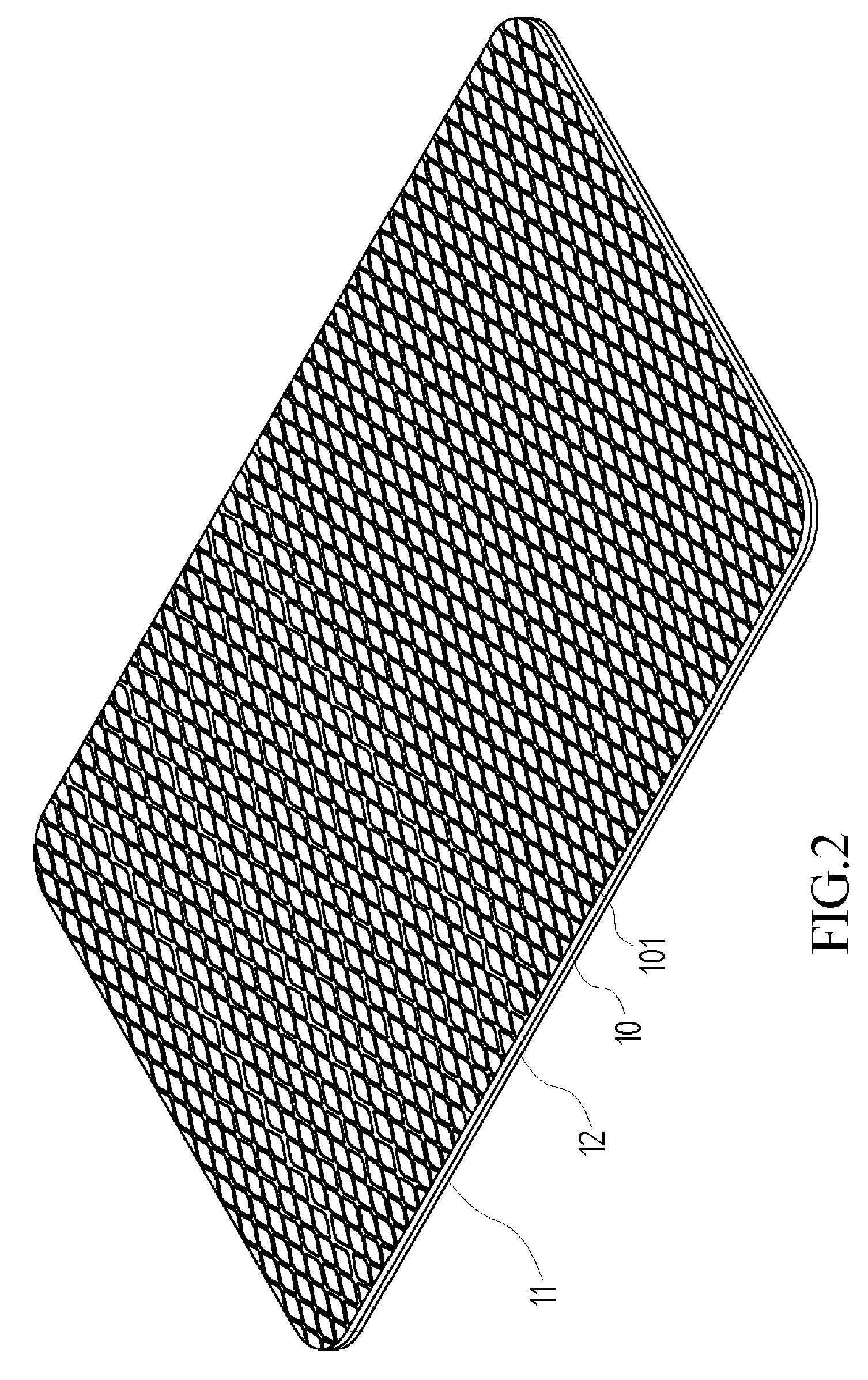

[0011]Referring to FIGS. 1 to 3, the foam pad of the present invention comprises a base 10 which is made by foam material such as rubber foam and includes honeycomb-shaped protrusions 101 formed on an underside thereof such that the base 10 can be well positioned on the floor and does not slip. A reinforcement layer 11 is attached to a top of the base 10 by resin and can be made by fabric. A cork layer 12 is attached to a top of the reinforcement layer 11 by resin.

[0012]The honeycomb-shaped protrusions 101 on the underside of the base 10 ensures that the foam pad does not slip or move on the floor and the reinforcement layer 11 is soft and flexible which securely connects the base 10 and the cork layer 12.

[0013]The cork layer 12 is made by natural material which has good ventilation and absorbs the user's sweat so that the top surface of the cork layer 12 keeps dry and clean.

[0014]The base 10, the reinforcement layer 111 and the cork layer 12 are flexible so that the foam pad can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com