Casing profiling and recovery system

a casing and recovery system technology, applied in the direction of fluid removal, explosive charges, wellbore/well accessories, etc., can solve the problems of various sized debris falling into or remaining in the wellbore, difficult sealing of irregularly shaped openings, and difficult to eliminate debris. , to achieve the effect of decreasing the amount of debris and increasing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

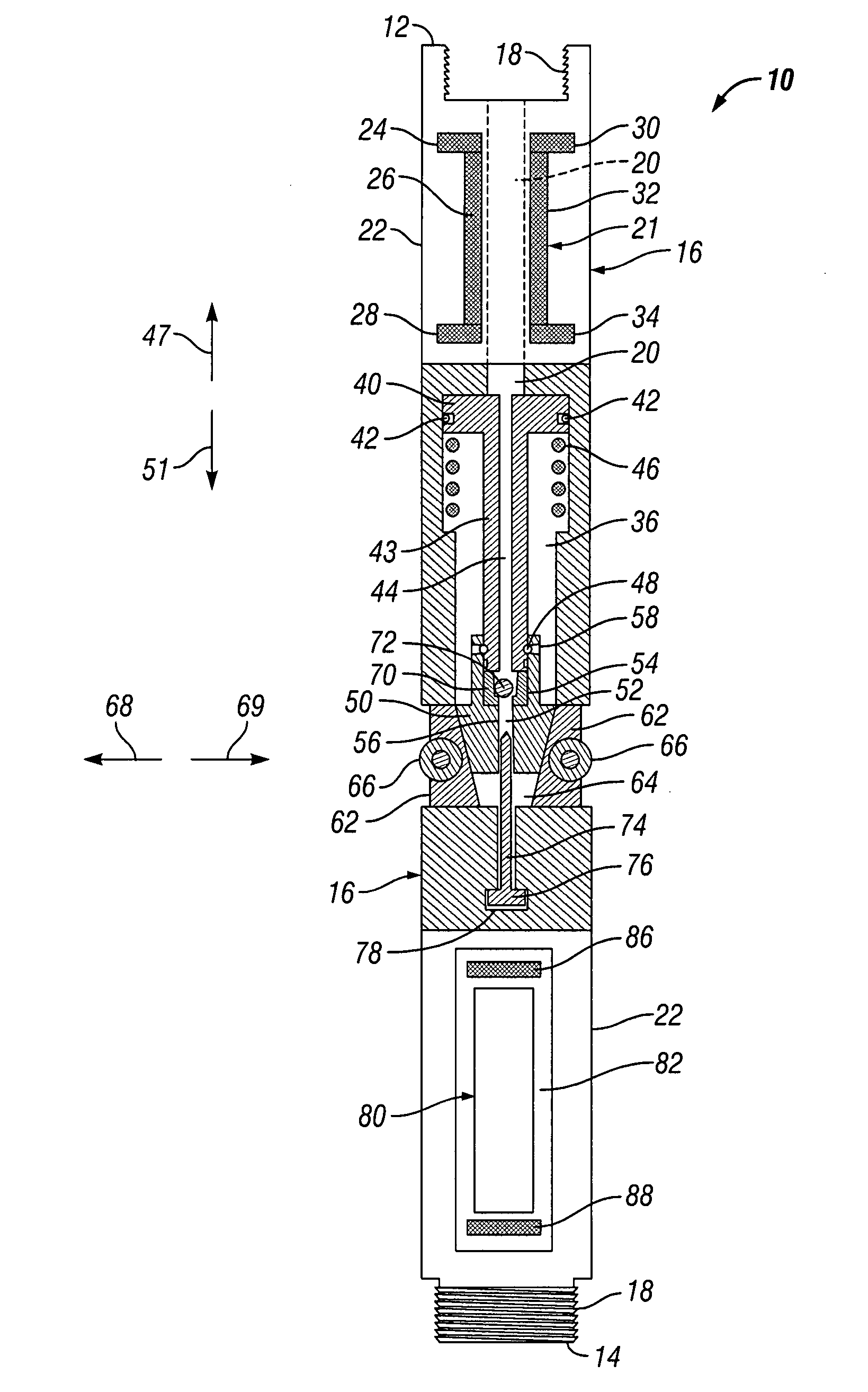

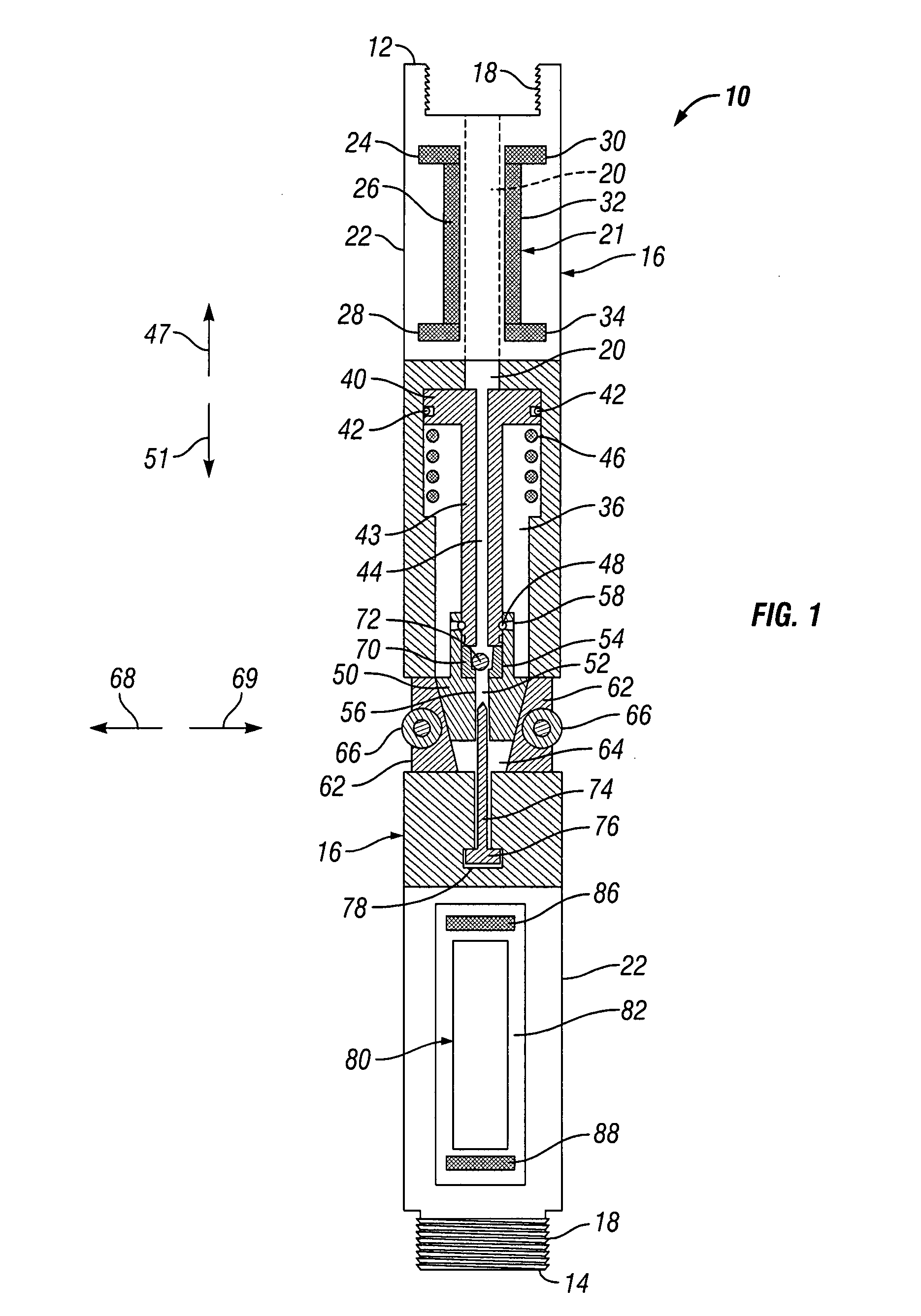

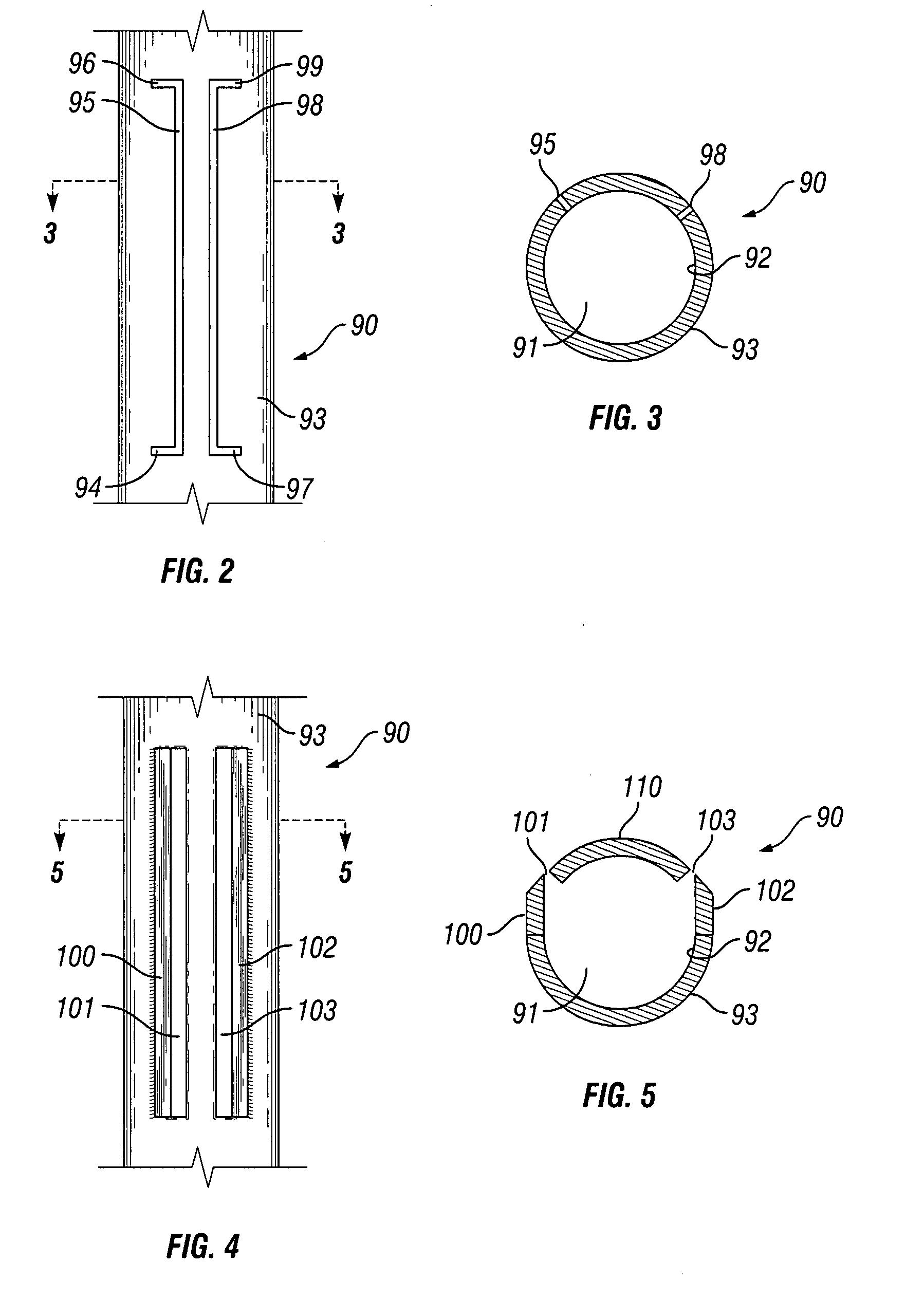

[0029]Referring now to FIGS. 1-12, casing cutting and recovery tool 10, or tool 10 or downhlole tool 10, comprises upper end 12, lower end 14 and housing 16. Upper end 12 and lower end 14 both include threads 18 for securing tool 10 to a casing, drill pipe, tubing string, or wireline (not shown) or other downhole tools (not shown). Housing 16 includes housing bore 20 longitudinally disposed at least partially through housing 16 and outer wall surface 22.

[0030]Tool 10 includes at least one cutting assembly 21. In the embodiment shown in FIG. 1, Cutting assembly 21 includes linear charges 24, 26, 28, 30, 32, 34 disposed along a radial arc of outer wall surface 22. Linear charges are known in the art and may be obtained from Accurate Arms Company, Inc. located in McEwen, Tenn. Briefly, linear charges 24, 26, 28, 30, 32, 34 are shaped explosive devices having a substantially V or U cross-section. When detonated, the explosive force is expelled out of an opening along the top of the V or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com