Flush or near-flush flooring transitions

a technology of transitions and flooring, applied in the direction of structural elements, building components, roof coverings, etc., can solve the problems of difficulty in covering gaps formed, problems encountered with conventional edge moldings, etc., and achieve the effect of increasing the efficient use of materials and reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

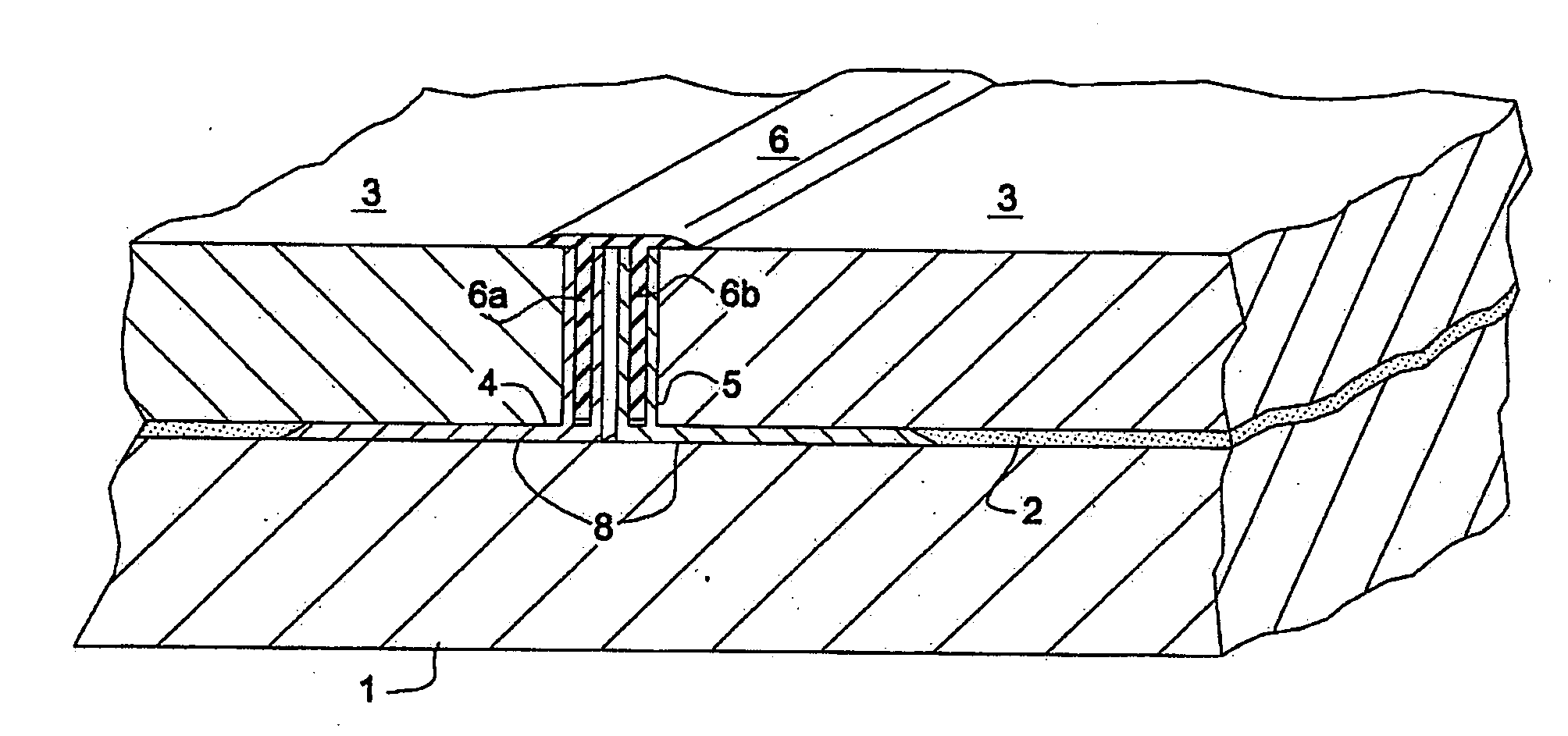

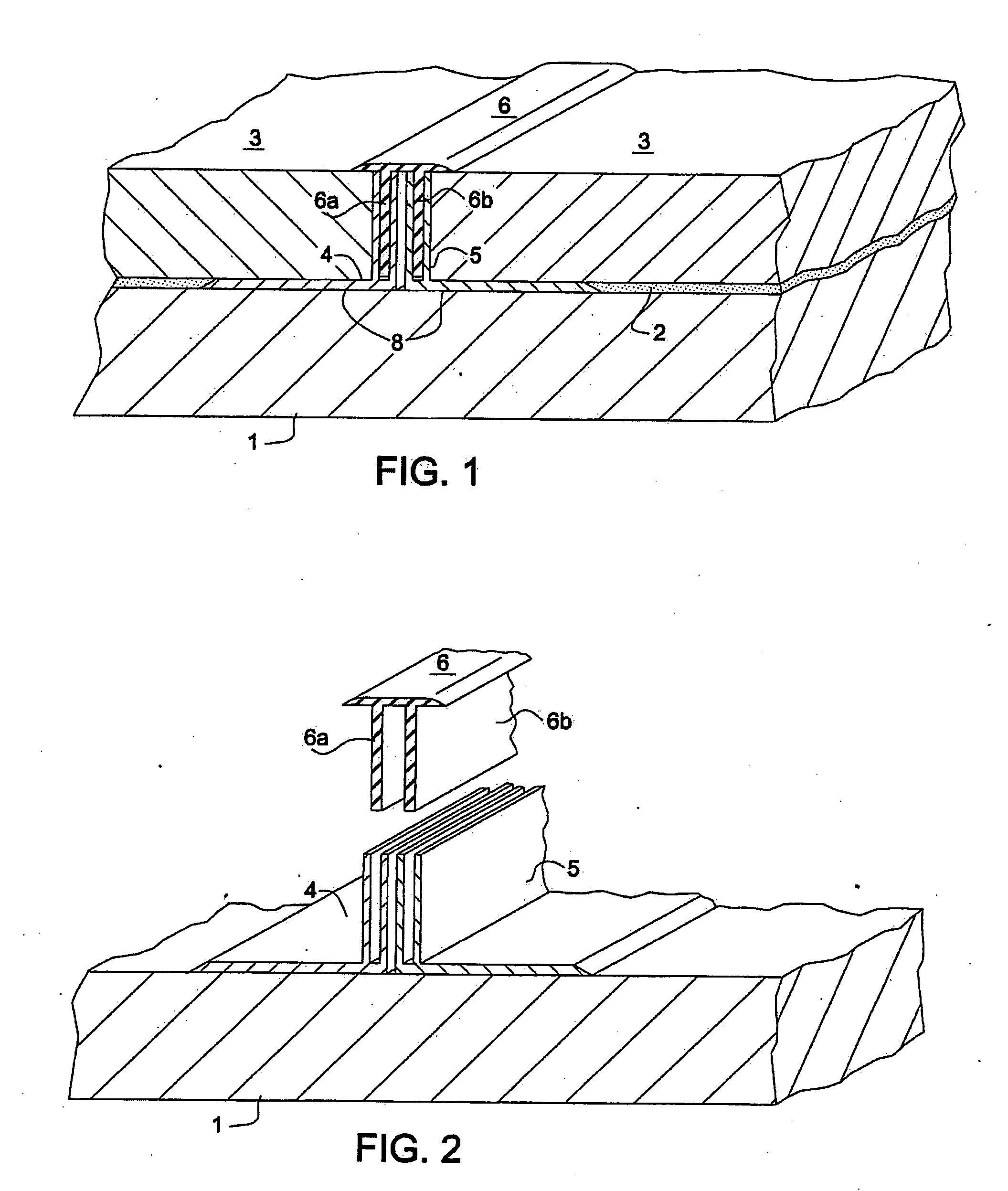

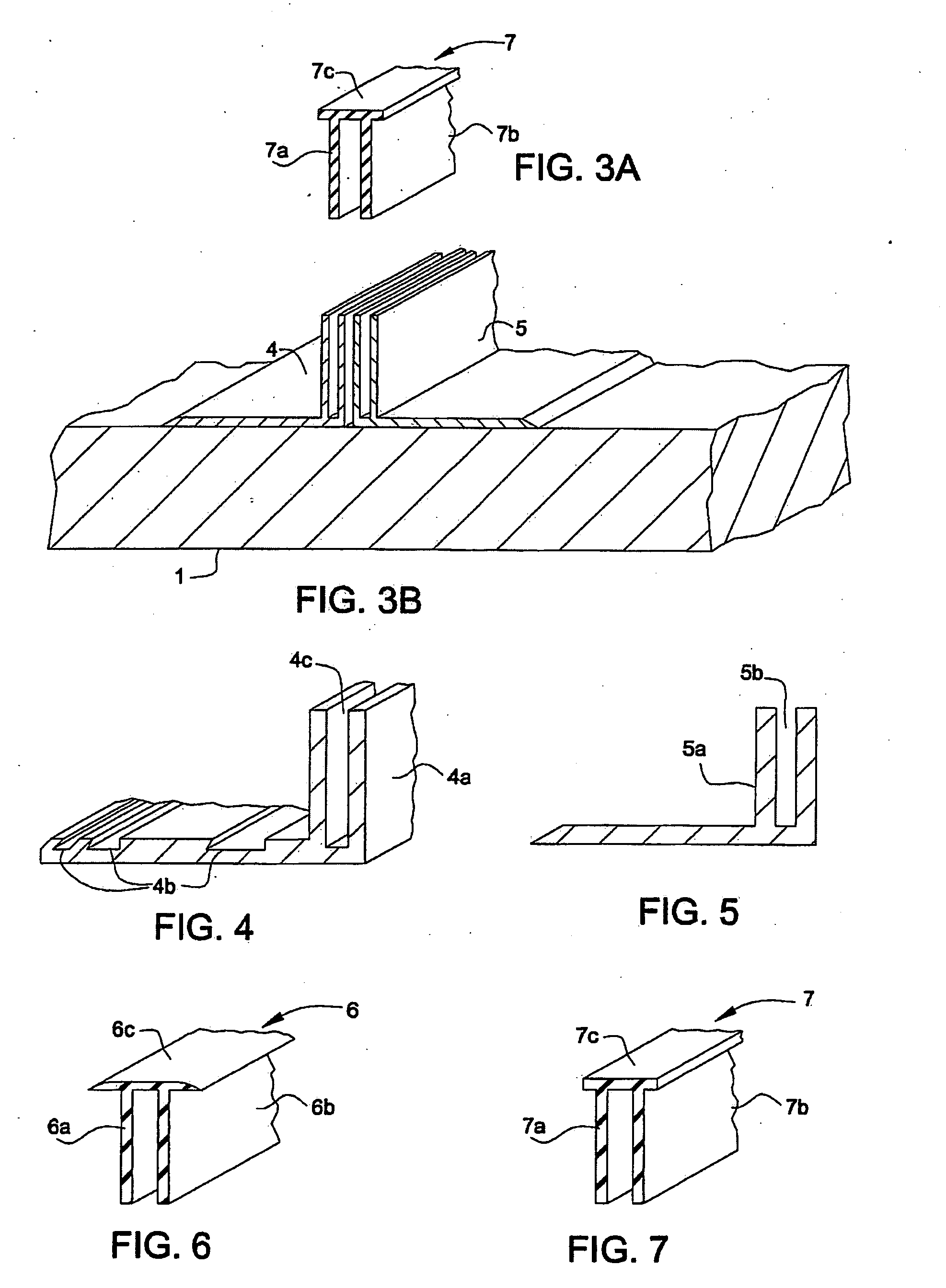

[0055]Generally, the invention is to be used above a subfloor 1, typically an underlayment 2, and between adjacent finished flooring elements 3. Underlayment 2 can be any type of conventional underlayment, e.g., foam, or film laid upon the subfloor or alternatively such underlayment may be affixed to flooring elements 3. As described herein, flooring elements 3 can, independently, be laminate panels, tiles (e.g., wood or ceramic), resilient flooring (e.g., vinyl), or carpet.

[0056]Two tracks, 4, 5 are preferably installed between subfloor 1 and one flooring element 3 to hold a T-molding in place. Tracks 4 and 5 can be attached to finished flooring 3, at horizontal surfaces thereof. It is additionally considered with the scope of the invention to attach track 4 to vertical edges of flooring elements 3. If finished flooring 3 has underlayment 2 affixed thereto, a portion of underlayment 2 is preferably removed, by, for example, being cut away, peeled back or shaved away, for direct con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com