Balloon catheters and methods for treating paranasal sinuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

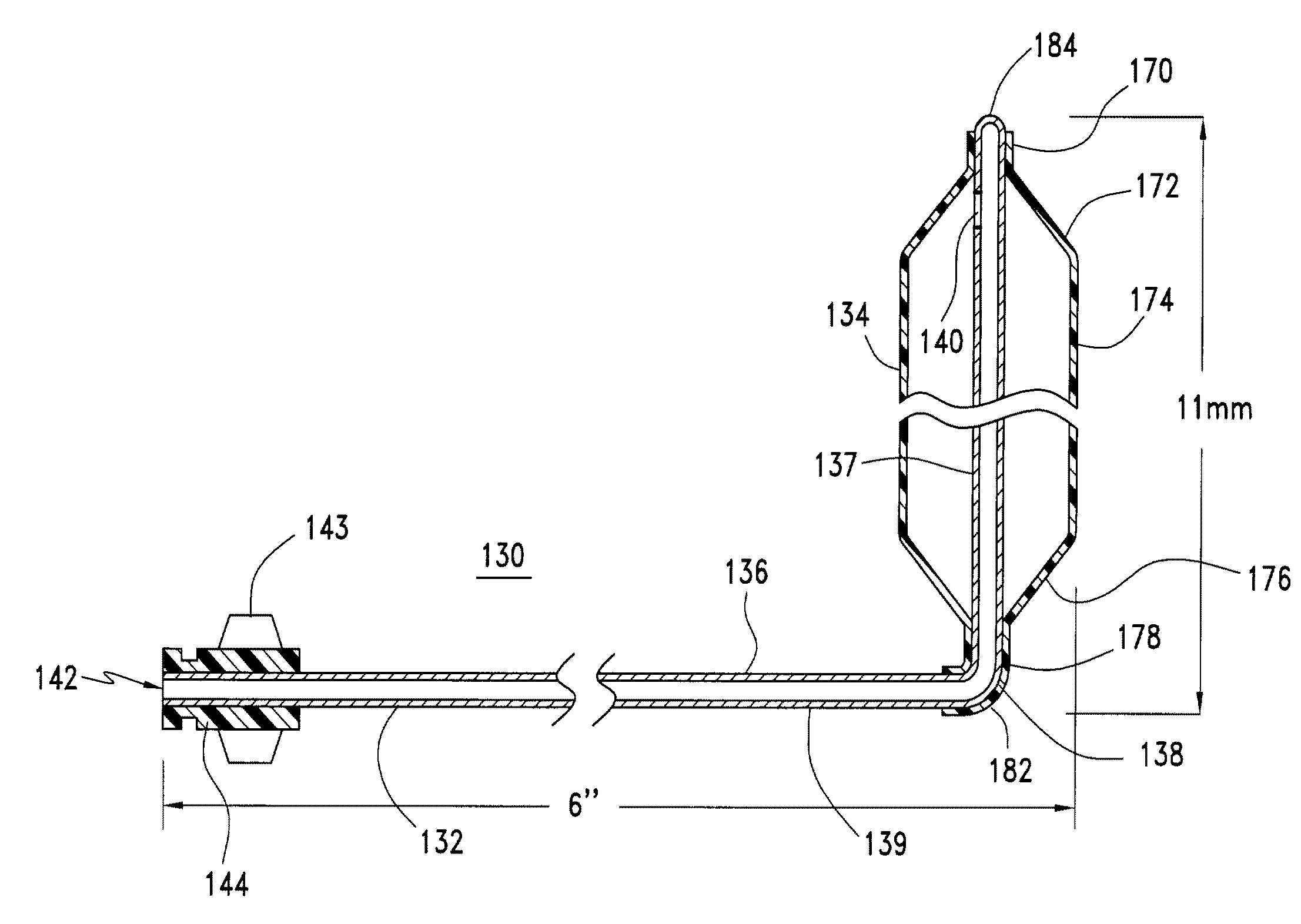

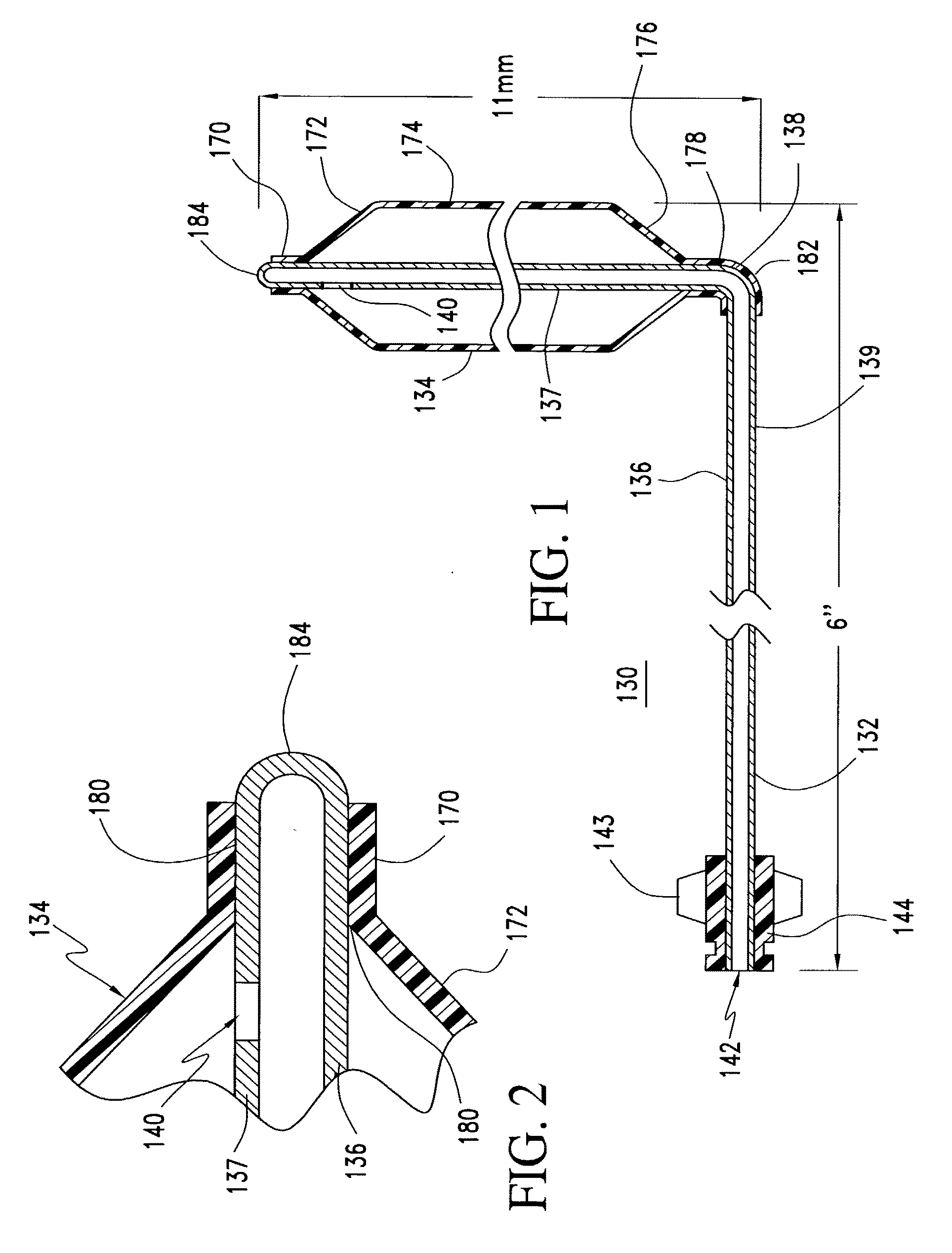

[0040] As shown in FIGS. 1 and 2, a sinus balloon catheter 130 of the invention is assembled from a tube 136, preferably a stainless steel hard tempered hypotube which has a circular bend 138 of 0.13″ radius such that distal segment 137 is oriented 70.degree. to 115.degree., preferably 90.degree., to proximal segment 139. A slot 140 is provided in segment 137. The distance from the distal tip 184 of distal segment 137 to the outer wall of proximal segment 139 of hypotube 136 is 4 mm to 30 mm, preferably 14 mm, as shown in FIG. 1. The distal tip 184 of the hypotube 136 is closed, whereas the proximal end 142 is open. However, the lumen of tube 136 may be closed in distal segment 137, up to 10 mm from distal tip 184, allowing distal tip 184 to remain open. In either case, tube 136 is closed distally of slot 140. The proximal end 142 of hypotube 136 is inserted into a mold for forming luer 144 and plastic is injected into the mold to form luer 144 attached to the end of proximal segmen...

second embodiment

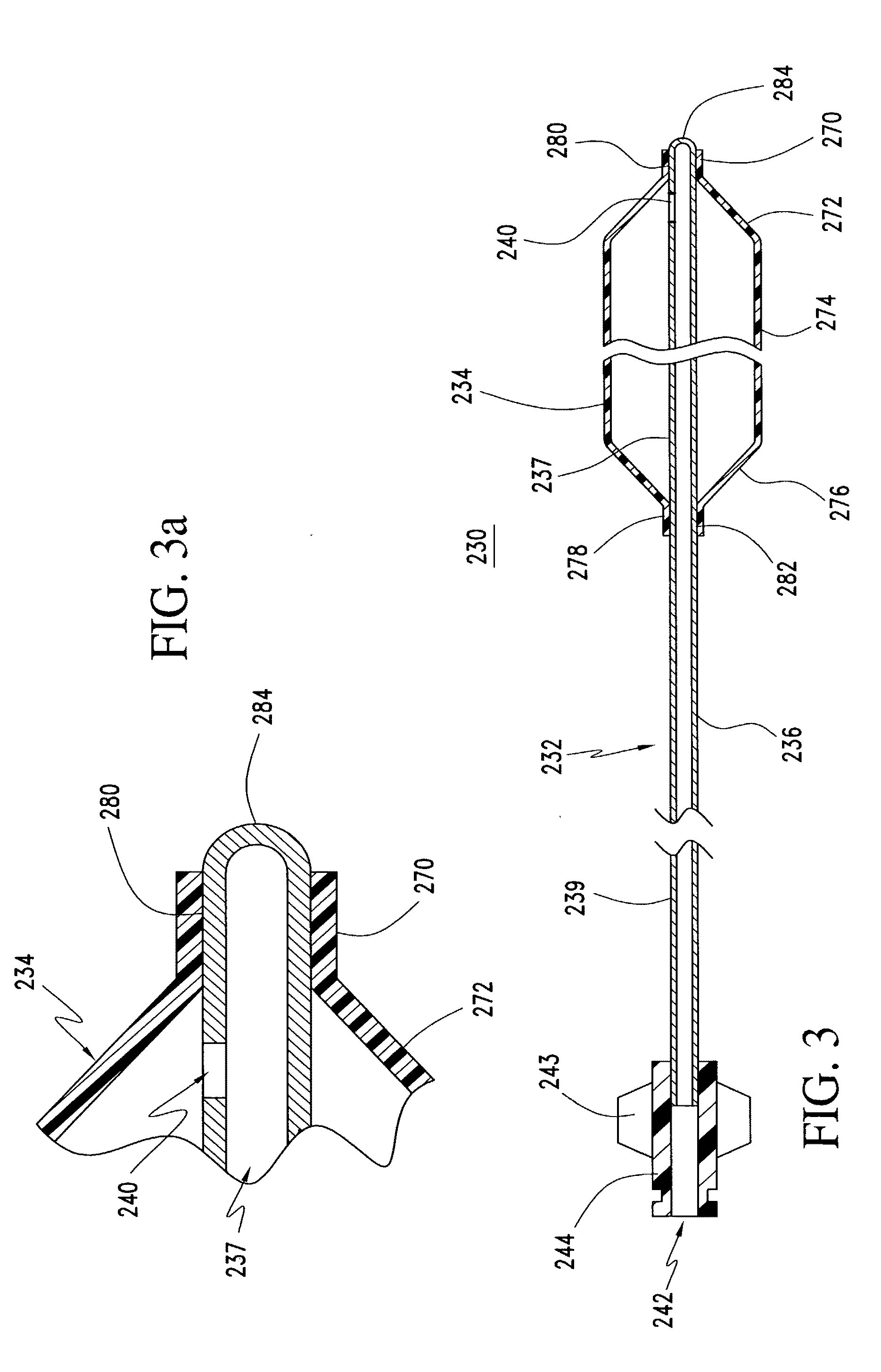

[0043] sinus catheter of the invention is shown in FIG. 3. The catheter 230 is assembled from a tube 236, formed of stainless steel hard tempered hypotube which is straight or has a mild circular bend distally such that distal segment 237 is oriented 130 to 180, preferably 180 degrees, to a long proximal segment 239. The distance from the distal tip 284 of distal segment 237 to the outer wall of proximal segment 239 of hypotube 236 is 10 to 100 mm, preferably 16 mm. The distal tip 284 of the hypotube 236 preferably is closed whereas the proximal end 242 is open. However, the lumen of tube 236 may be closed 0 to 10 mm from distal tip 284 allowing distal tip 284 to be open. The proximal end 242 of hypotube 236 is inserted into a mold for forming luer 244. Heated plastic is injected into the mold to form luer 244 attached to the end of proximal segment 239. The inner diameter of luer 244 matches the external diameter of hypotube 236. The luer 244 has wings 243 or expansions on it to en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap