Automatic document feeder having detachable sheet-pressing slice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

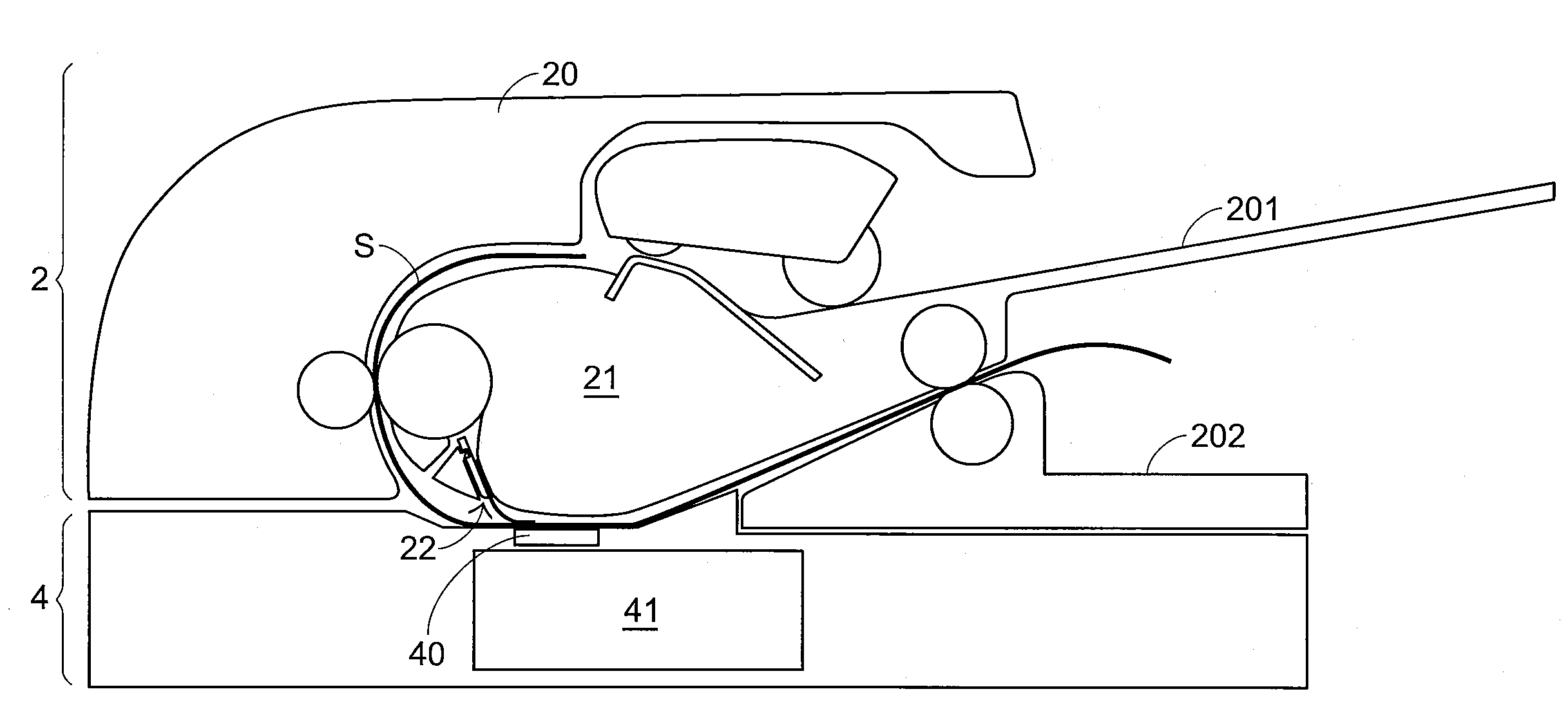

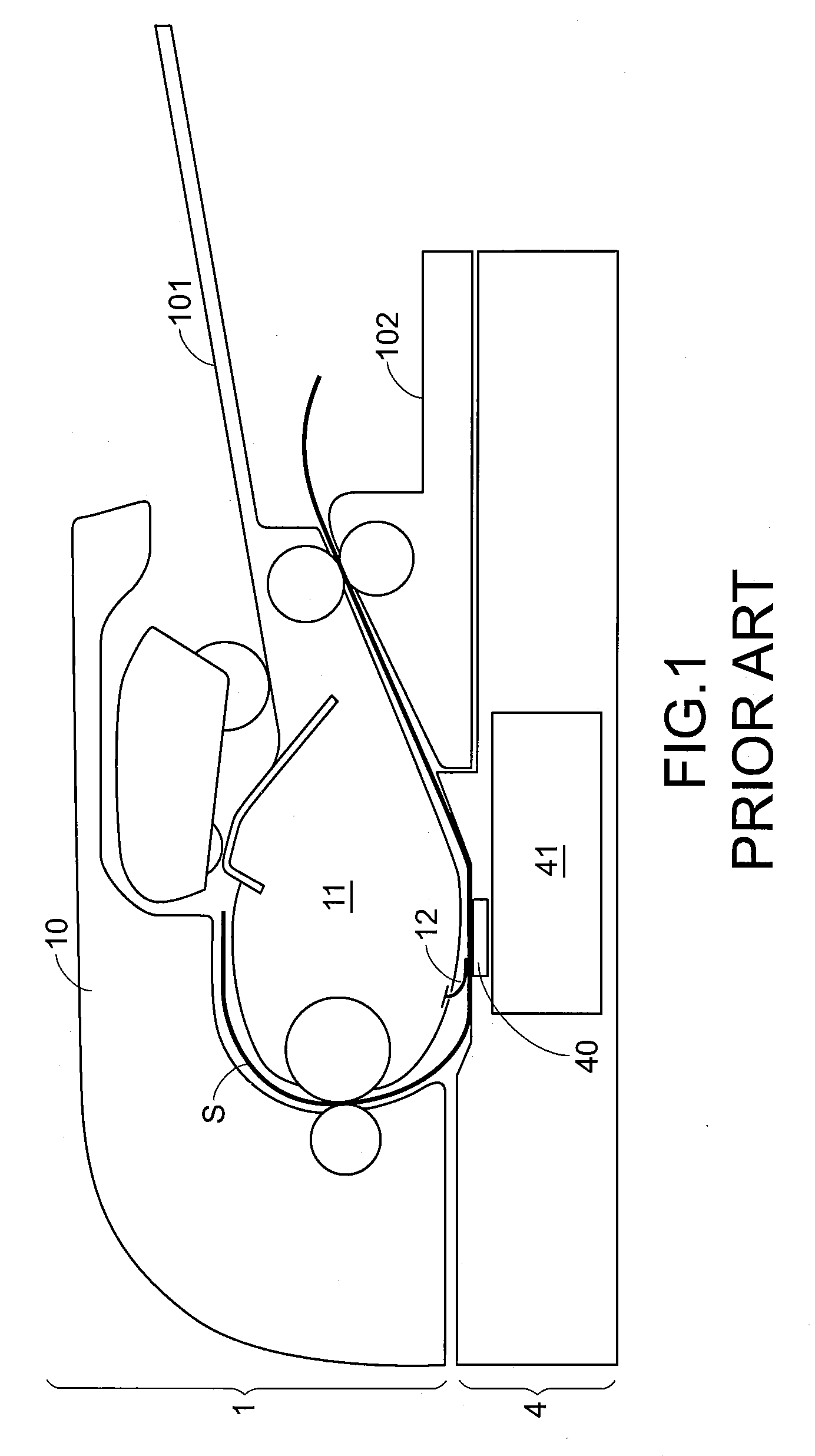

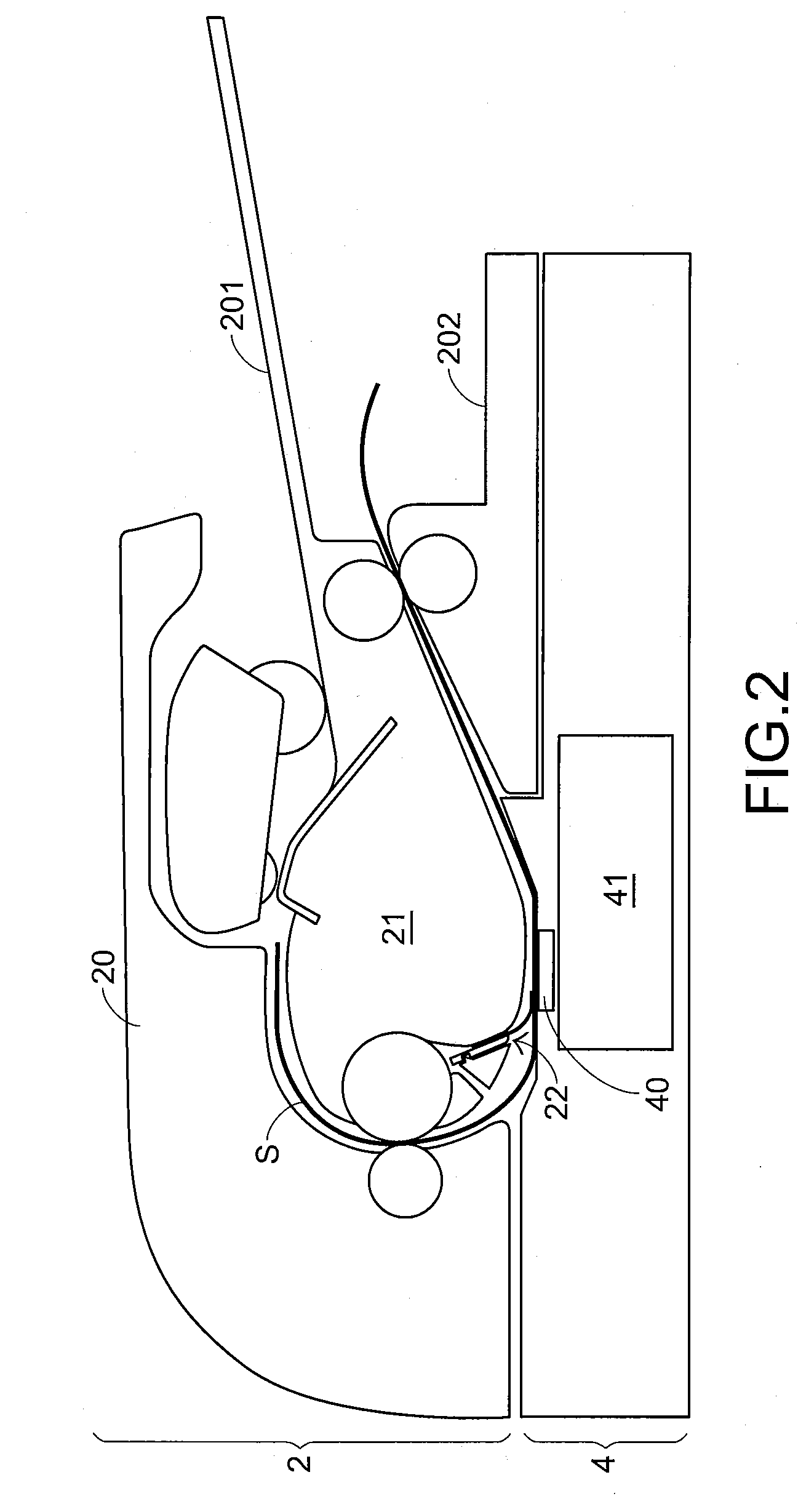

[0031]Hereinafter, the operations of the detachable sheet-pressing slice 22 will be illustrated with reference to the schematic partial enlarged cross-sectional views of FIGS. 3A˜3D according to the present invention.

[0032]In FIG. 3A, the detachable sheet-pressing slice 22 has been mounted on the lower part of the sheet-feeding mechanism 21 of the automatic document feeder 2 for pressing the document S passing through the scanning window 40. As shown in FIG. 3B, the detachable sheet-pressing slice 22 is separated from the automatic document feeder 2. The detachable sheet-pressing slice 22 includes a fixing member 220 and a sheet-pressing member 221. The fixing member 220 is fixed on the lower part of the sheet-feeding mechanism 21 and used to support the sheet-pressing member 221. The sheet-pressing member 221 imparts a downward pressing force to the document S, thereby preventing the document S from rising up when passing through the scanning window 40 of the scanning apparatus 4. ...

second embodiment

[0036]In the automatic document feeder, the complementary engaging elements include the hook structure 3100 protruded from an inner wall of the retaining recess 310 and the concave structure 321 of the sheet-pressing member 320. By engagement of these engaging elements, the detachable sheet-pressing slice 32 is fixed on the lower part of the sheet-feeding mechanism 31. It is noted that, however, those skilled in the art will readily observe that numerous modifications and alterations may be made while retaining the teachings of the invention. For example, as shown in FIG. 4B, one or more salient structures 322 are protruded from the sheet-pressing member 320. The salient structures 322 are sustained against the inner wall of the of the retaining recess 310, thereby further facilitating fixing the detachable sheet-pressing slice 32 on the lower part of the sheet-feeding mechanism 31.

[0037]In the above embodiments, the concave structures 2101, 2200 and 321 are indentations. Alternativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com