Preparation method of sparse/dense periodically stacked flocculent fiber filtering material

A technology of fiber filtration and flocculation, which is applied in the field of preparation of sparse/dense periodic stacked flocculation fiber high-temperature filter materials, can solve the problems of long preparation period, decreased filtration accuracy, and limited dust holding capacity, etc., and achieves convenient preparation process and improved The effect of improving the service life and dust holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

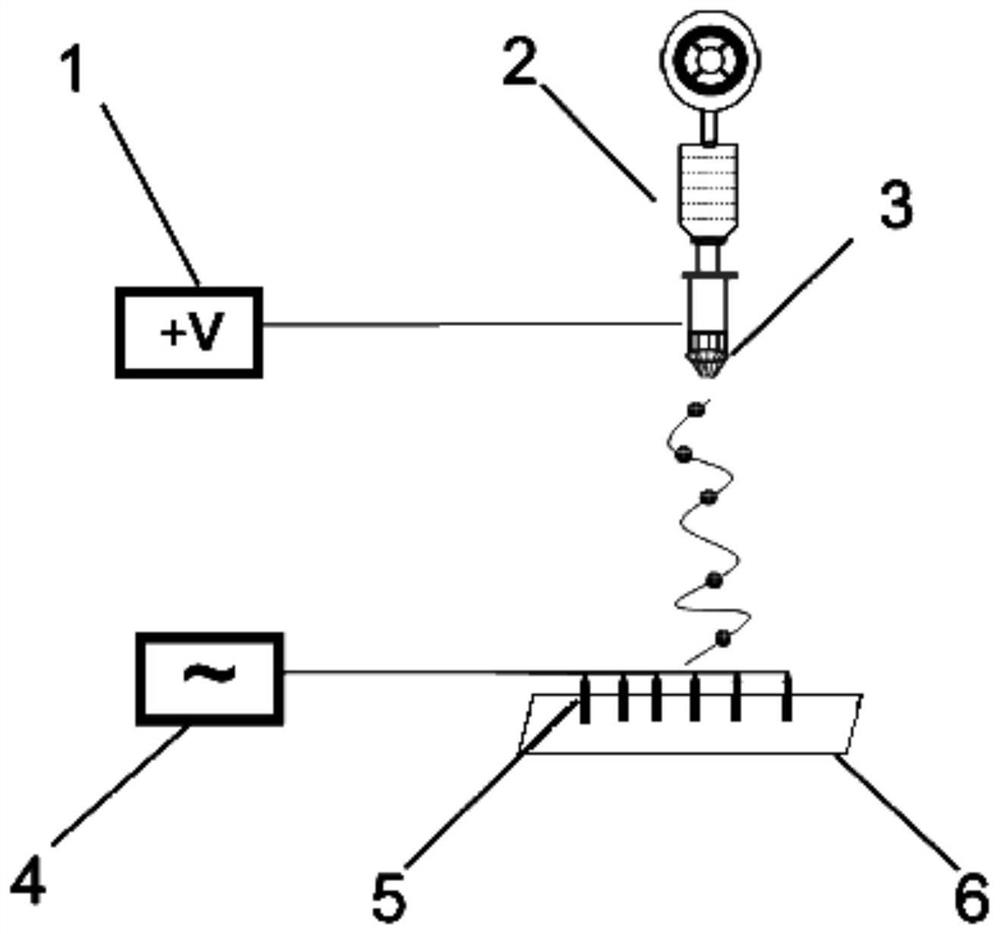

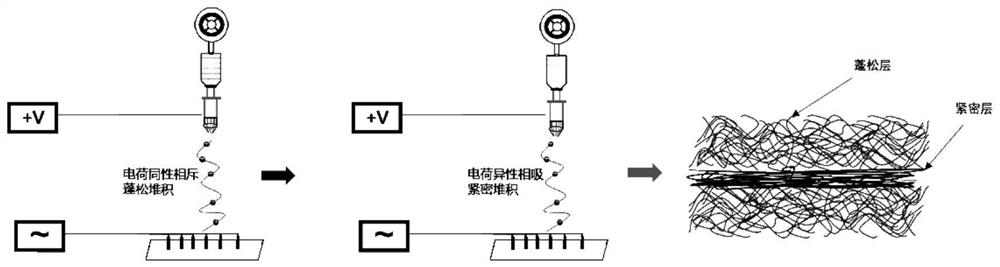

[0034] A method for preparing a sparse / dense periodic stacked floc fiber filter material: inject the spinning liquid into the electrospinning device, and control the needle-type auxiliary electrode 5 on the receiving substrate 6 to be negatively or positively charged during the spinning process. The spinning jet is subjected to attraction or repulsion when it is close to the receiving substrate 6, thereby obtaining fluffy-dense-fluffy periodic stacked floc fiber high-temperature filter material in one step; the spinning solution is made of polyimide (content is 6wt%, temperature-resistant 250°C), carbon nanotubes (content 0.02wt%, average particle size 80nm) and N,N-dimethylformamide.

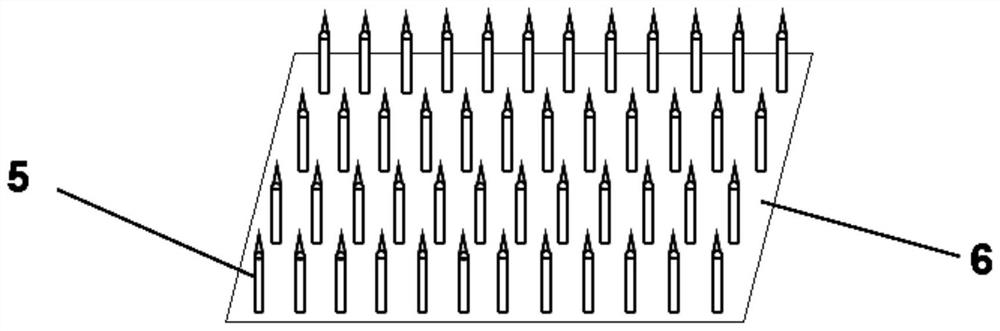

[0035] The electrospinning device is composed of a micro-needle auxiliary electrode 5, an alternating power supply 4, a liquid supply device 2, a slit spinneret 3 and a high-voltage power supply 1; the micro-needle auxiliary electrode 5 is composed of metal needles arranged in an array, The arr...

Embodiment 2

[0038] A method for preparing a sparse / dense periodic stacked floc fiber filter material: inject the spinning liquid into the electrospinning device, and control the needle-type auxiliary electrode 5 on the receiving substrate 6 to be negatively or positively charged during the spinning process. The spinning jet is subjected to attractive or repulsive force when it is close to the receiving substrate 6, thereby obtaining fluffy-dense-fluffy periodic stacked floc fiber high-temperature filter material in one step; ℃), conductive titanium dioxide (content 0.005wt%, average particle size 30nm) and N,N-dimethylacetamide.

[0039] The electrospinning device is composed of a micro-needle auxiliary electrode 5, an alternating power supply 4, a liquid supply device 2, a slit spinneret 3 and a high-voltage power supply 1; the micro-needle auxiliary electrode 5 is composed of metal needles arranged in an array, The arrangement of the metal needles is rectangular, the material is aluminu...

Embodiment 3

[0042] A method for preparing a sparse / dense periodic stacked floc fiber filter material: inject the spinning liquid into the electrospinning device, and control the needle-type auxiliary electrode 5 on the receiving substrate 6 to be negatively or positively charged during the spinning process. The spinning jet is subjected to attraction or repulsion when it is close to the receiving substrate 6, thereby obtaining fluffy-dense-fluffy periodic stacked floc fiber high-temperature filter material in one step; the spinning solution is made of polyimide (content is 6wt%, temperature-resistant 230°C), conductive iron dioxide (content 0.02wt%, average particle size 80nm) and N-methylpyrrolidone.

[0043] The electrospinning device is composed of a micro-needle auxiliary electrode 5, an alternating power supply 4, a liquid supply device 2, a slit spinneret 3 and a high-voltage power supply 1; the micro-needle auxiliary electrode 5 is composed of metal needles arranged in an array, Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com