Lightweight, shock-absorbing package

a shock-absorbing package and light weight technology, applied in the field of light weight and shock-absorbing packages, can solve the problems of increasing the need of mail or otherwise ship fragile objects, and the increase of the weight of the shipping container, so as to achieve the effect of reducing shipping costs, being easy to produce and assemble, and being inexpensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

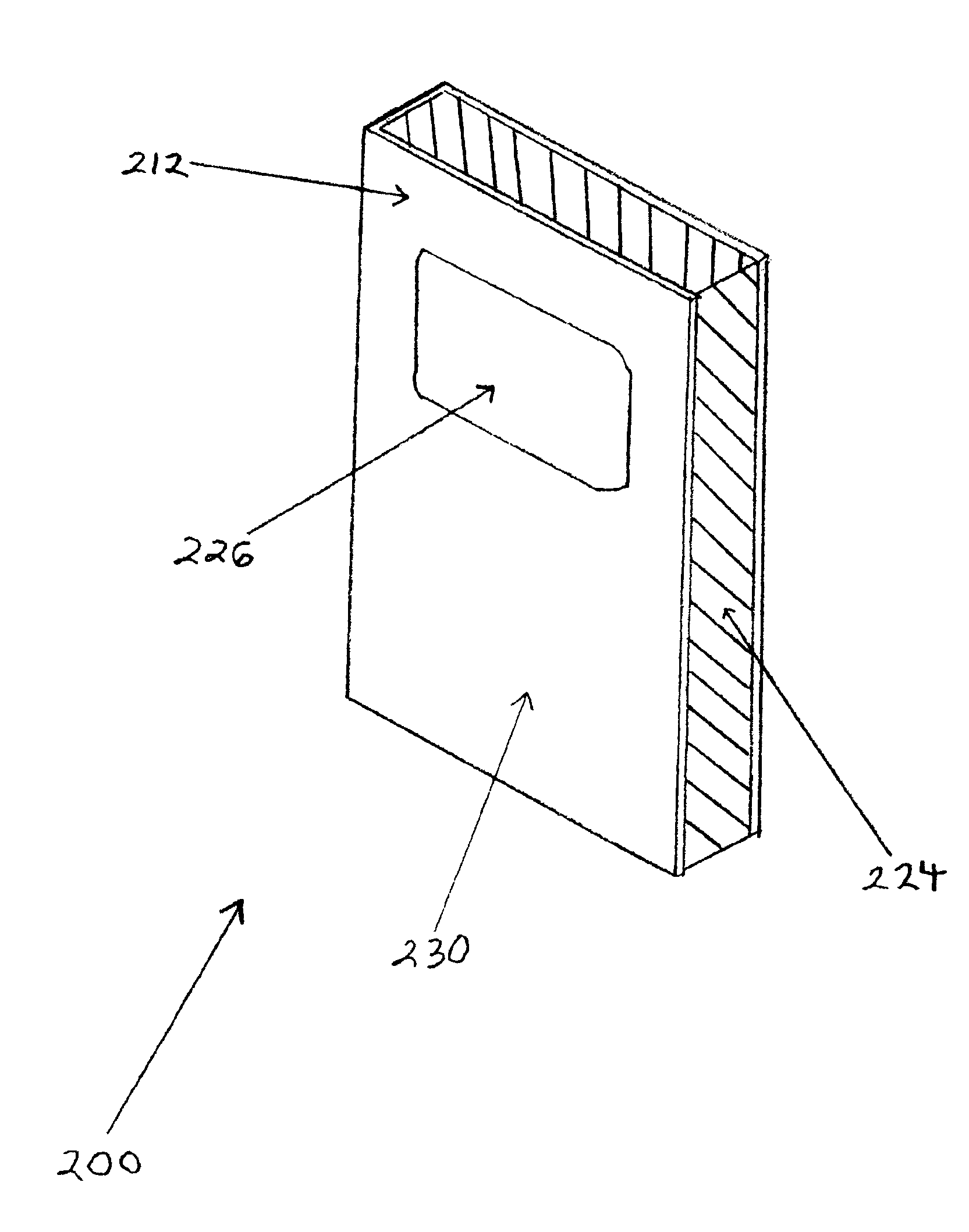

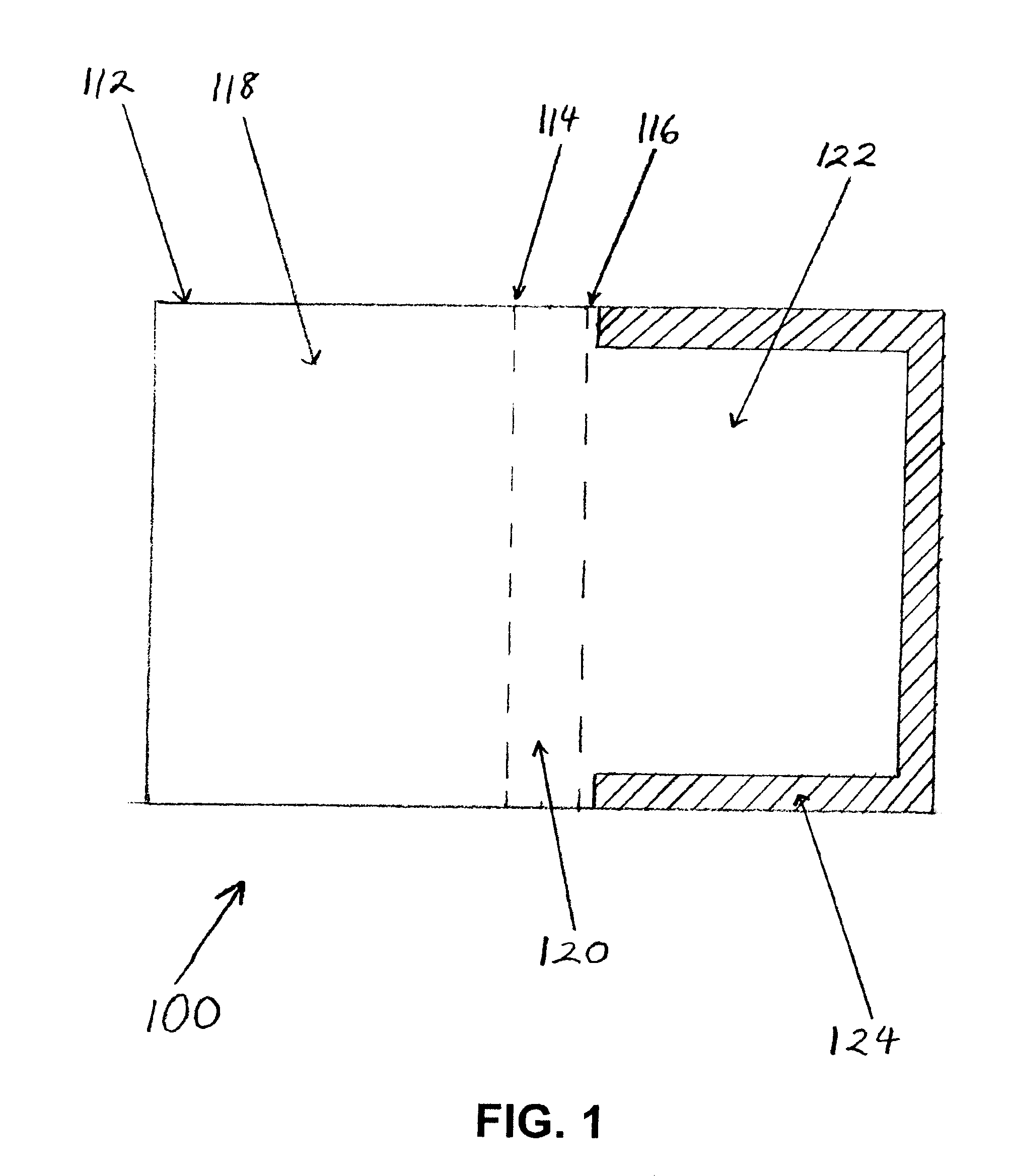

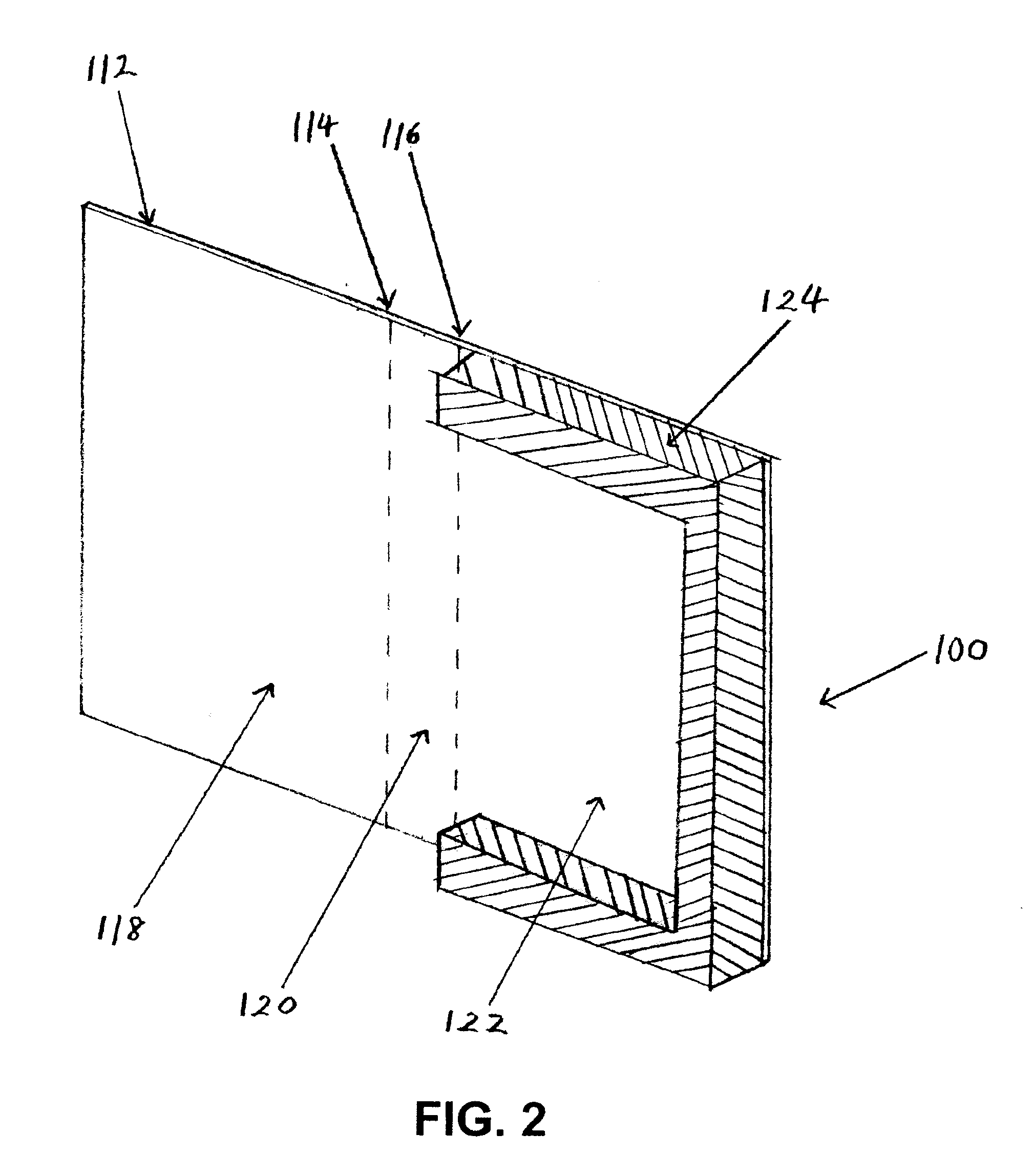

[0023]Referring now more particularly to FIGS. 1, 2, 3 and 4 of the accompanying drawings, there is illustrated a lightweight, shock-absorbent package constructed in accordance with the preferred embodiments of the present invention.

[0024]The present invention 100 shown in plan view in FIG. 1 includes a relatively stiff substantially flat sheet 112 having front and back sides that is divided by two creased fold lines 114,116 advantageously into three sections, namely, first section 118, spine section 120, and second section 122. First section 118 and second section 122 are of equal size, while the spine section 120 is considerably smaller, with a height equal to that of sections 118,122 but a width that is equal to the desired thickness of the package. When forming the advantageous package, first and second sections 118,122 are folded back along fold lines 114,116 toward one another about spine section 120, so that the back sides of the first and second sections are brought into a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com