Abrasive article and method of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

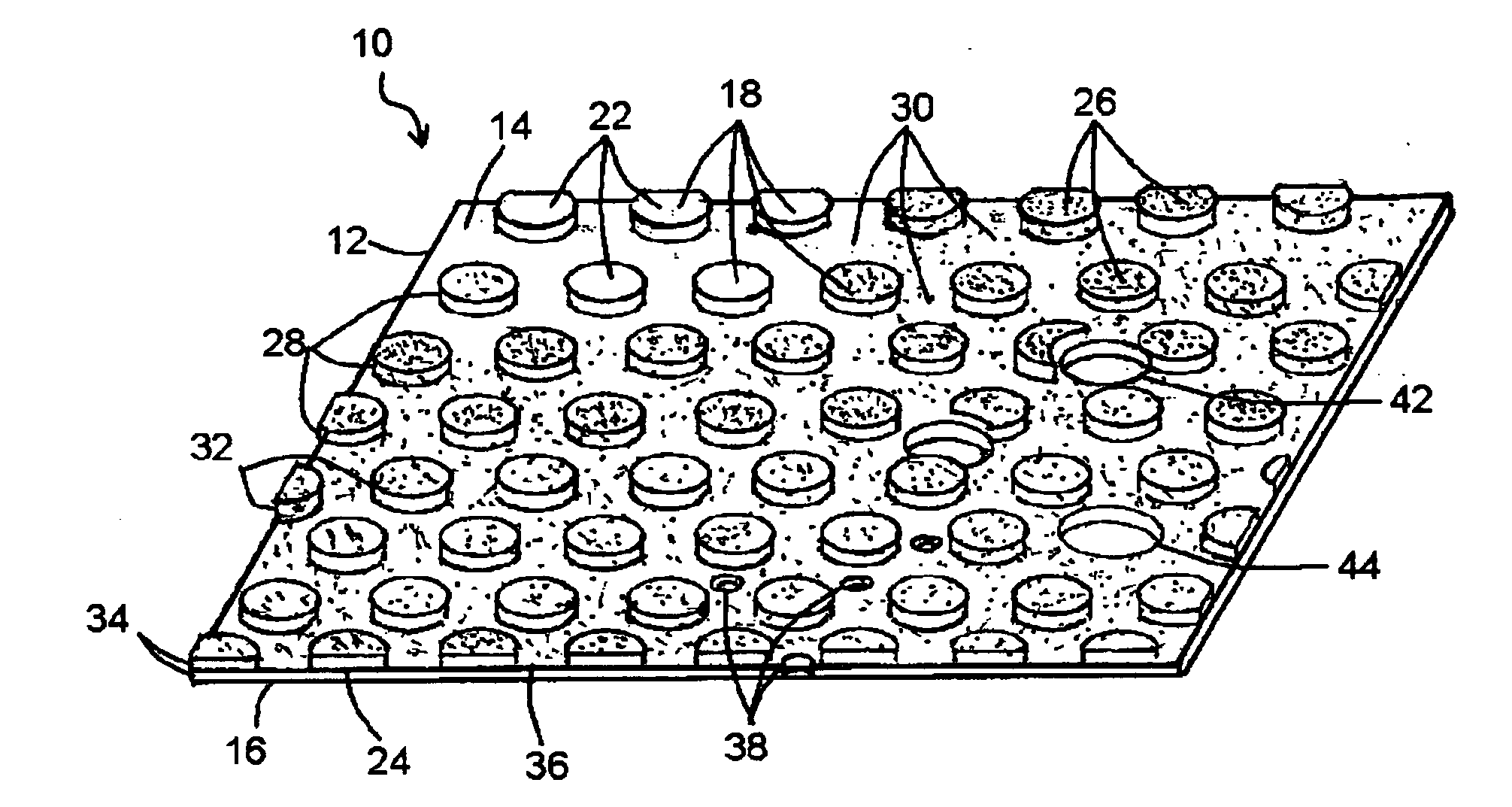

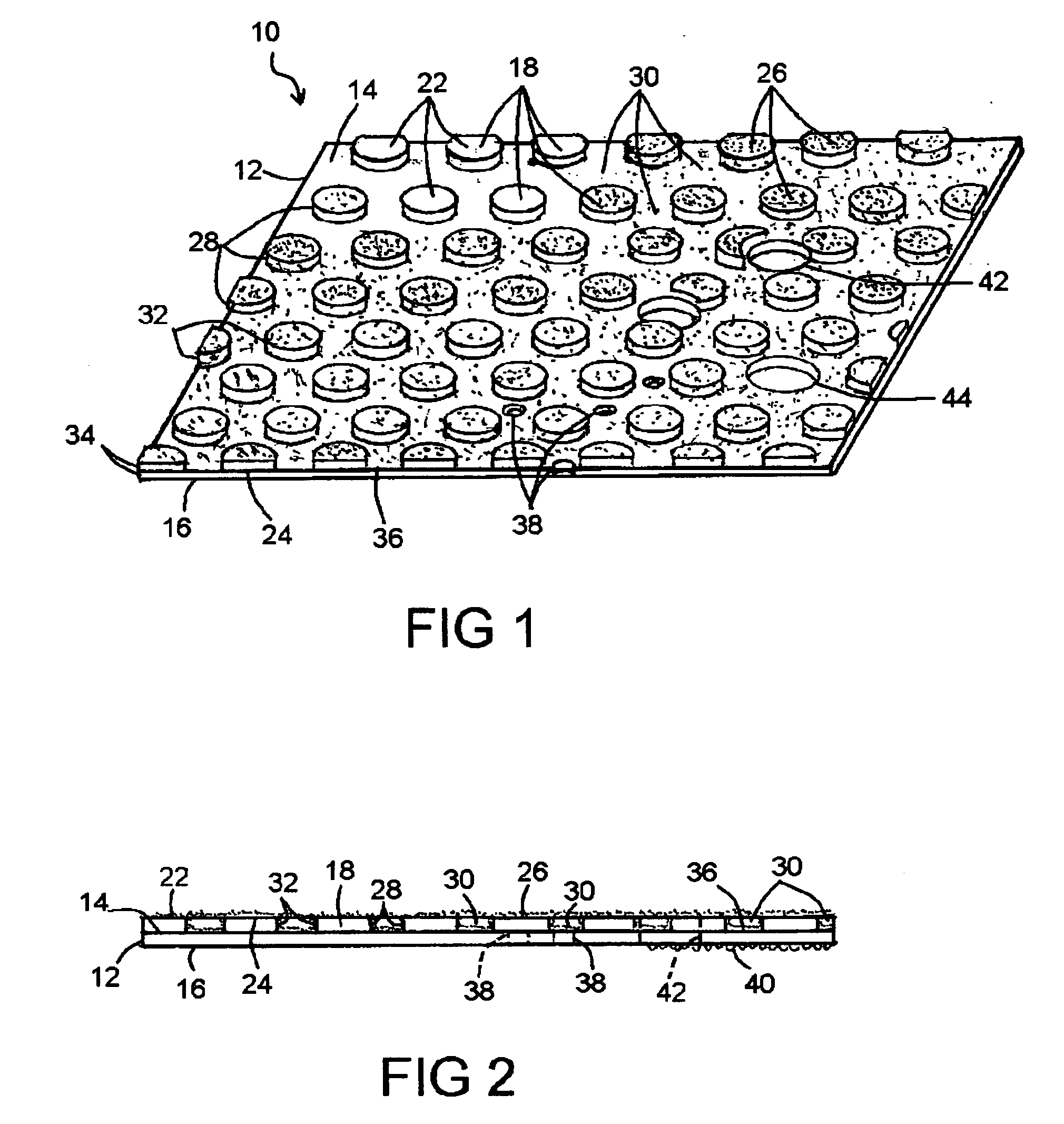

[0034]The present invention is an abrasive sheet material 10 and a method of forming and making the abrasive sheet material.

[0035]The abrasive sheet material comprises a first sheet having a first major surface and a second major surface and second sheets having first major surfaces and second major surfaces wherein the second major surfaces of the second sheets are affixed to the first major surface of the first sheet and spaces exist between the second sheets wherein said spaces form pathways that interweave between the second sheets wherein the pathways communicate with each other and form a network of pathways and, at least one aperture extends from at least the first major surface of the first sheet to the second major surface of the first sheet and communicates with at least one of the pathways. Abrasive particles are coated onto at least the first major surface of the second sheets forming an abrasive first major surface.

[0036]During sanding operations wherein the abrasive sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abrasive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com