Forklift Mast

a technology of forklifts and masts, applied in the field of forklift masts, to achieve the effect of reducing the rigidity to the weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

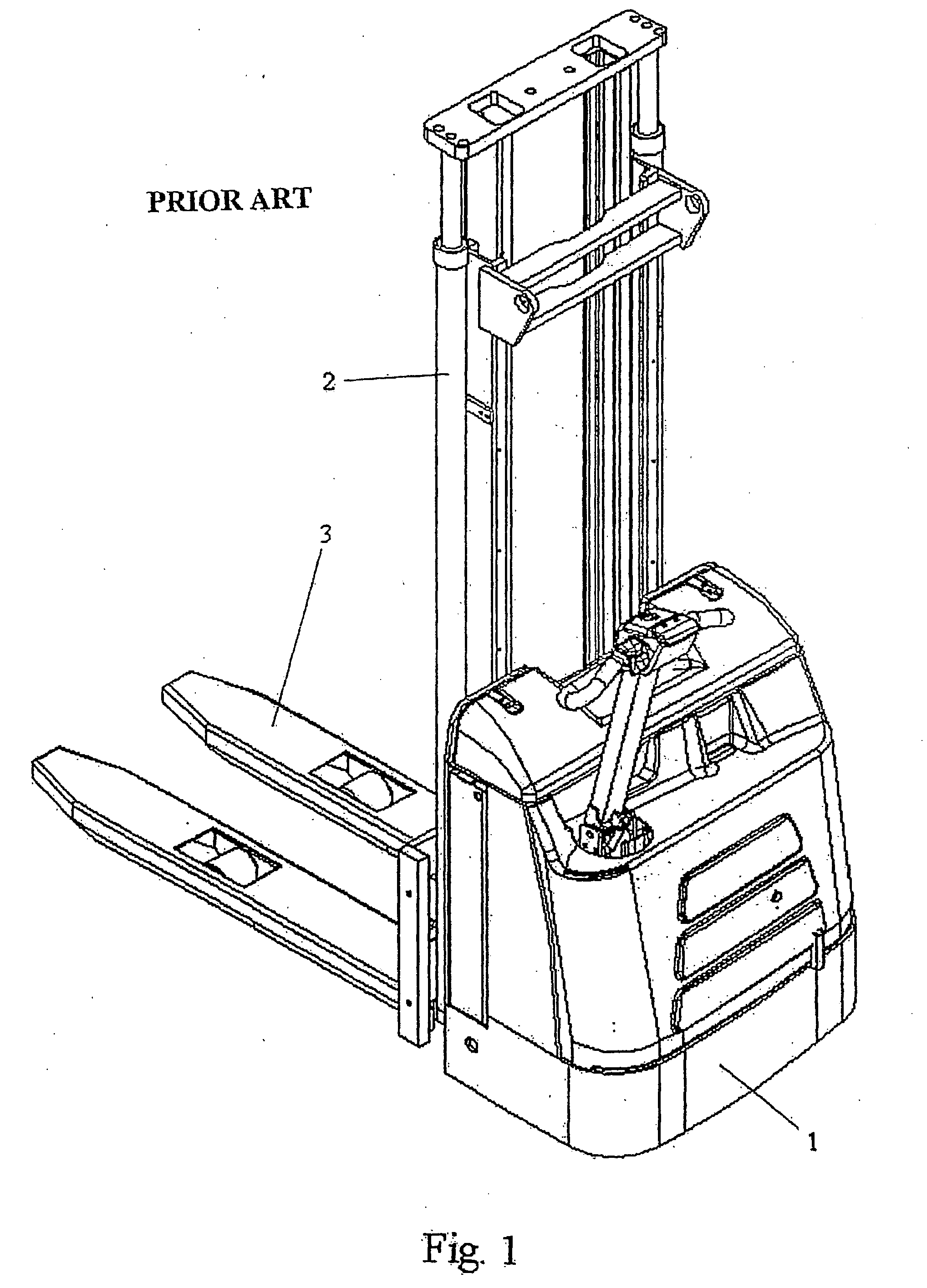

[0027]FIG. 1 illustrates a known version of a mast forklift. The frame 1 of the mast forklift comprises an attached mast construction and hydraulic cylinder construction 2, by means of which the hoisting cradle 3 can be lifted. In this case, the hoisting cradle 3 is a fork cradle. The hoisting cradle 3 is lifted in two or more steps depending on the mast construction.

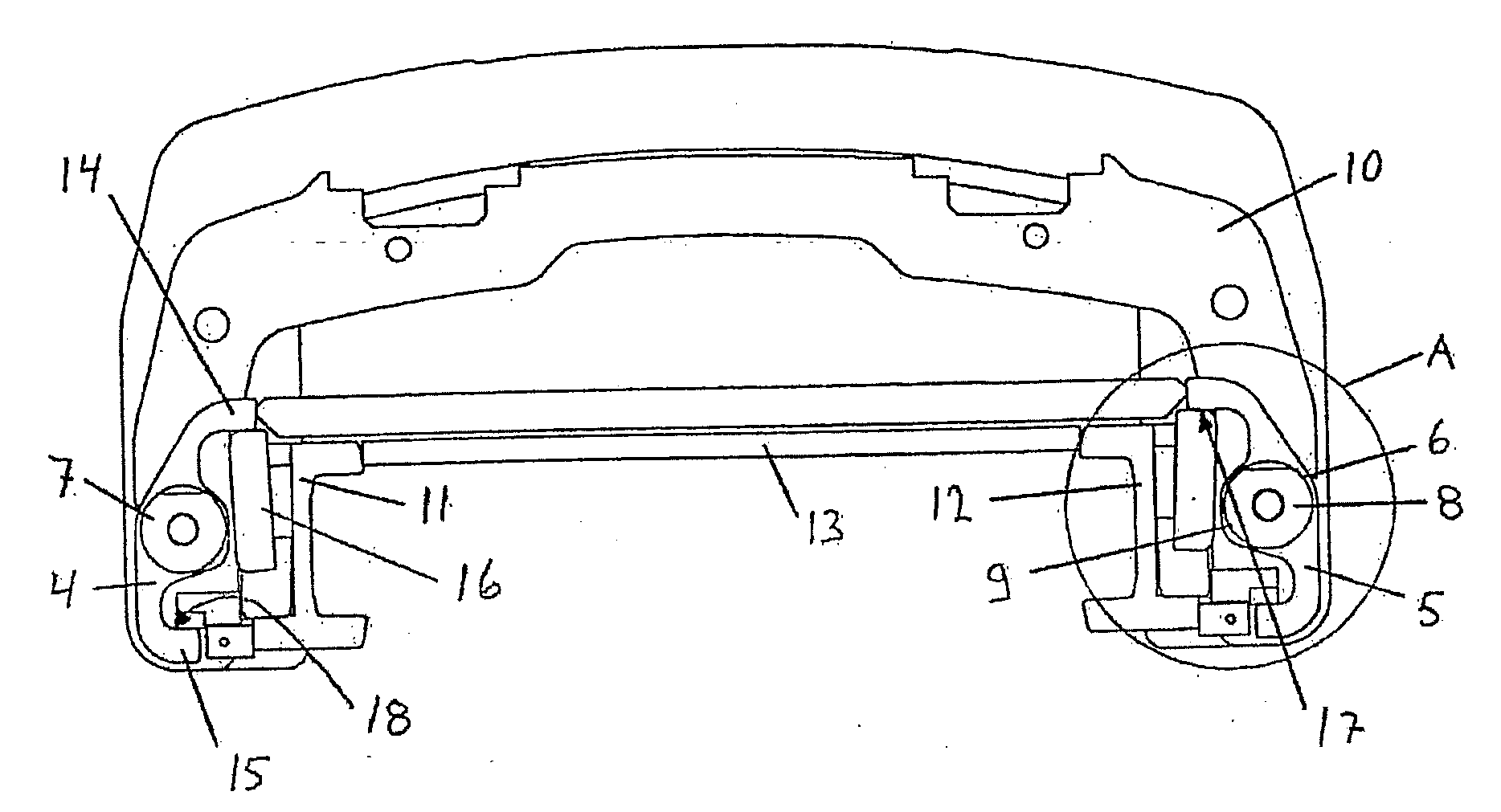

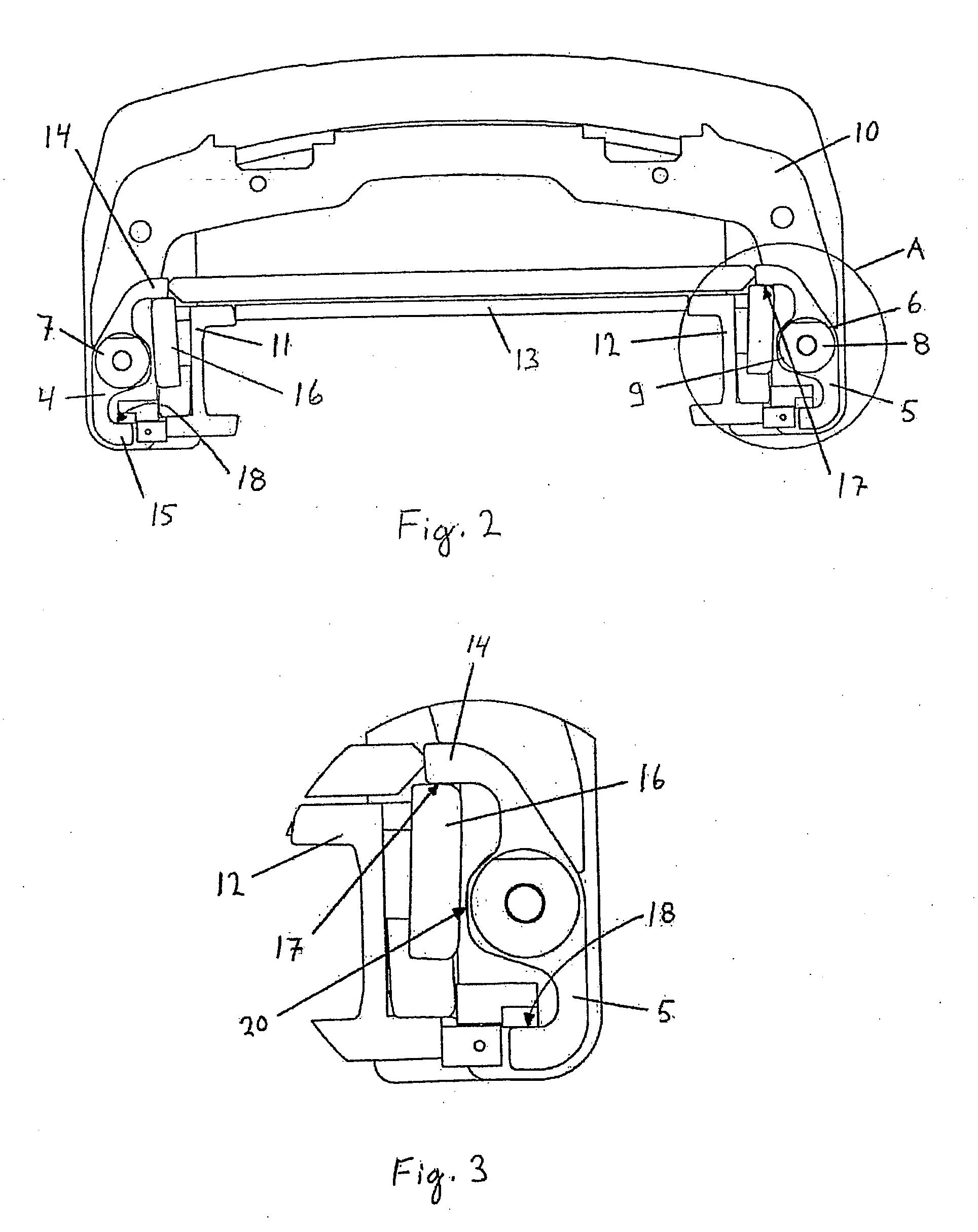

[0028]FIG. 2 is a cross-sectional top view of the mast construction of the mast forklift of the invention. The figure illustrates the integrally constructed substantially vertical beams 4 and 5, comprising integrated cylinder liners 6 with pistons 7 and 8. The cylinder liners 6 are borings extending longitudinally through the integral beams 4 and 5, the borings being sealed e.g. at their lower end by a pressure bushing or a plug and equipped at their upper end with packing boxes 9 in order to seal and guide pistons 7 and 8. The packing boxes have been mounted by welding or any similar method outside the cylinder liners,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com