Heat Exchanger

a technology of heat exchanger and heat exchanger plate, which is applied in the direction of indirect heat exchanger, laminated elements, lighting and heating apparatus, etc., can solve the problems of inability to use heat exchanger and relatively large edges, and achieve the effect of reducing time required, preventing mutual displacement of stacked plates, and quick and cost-effective manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

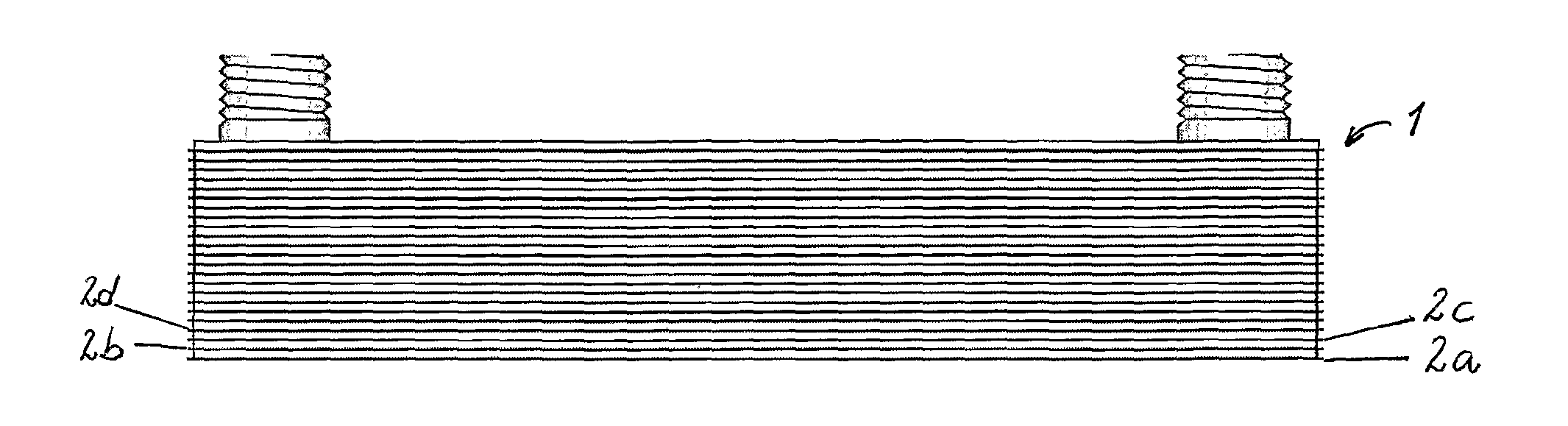

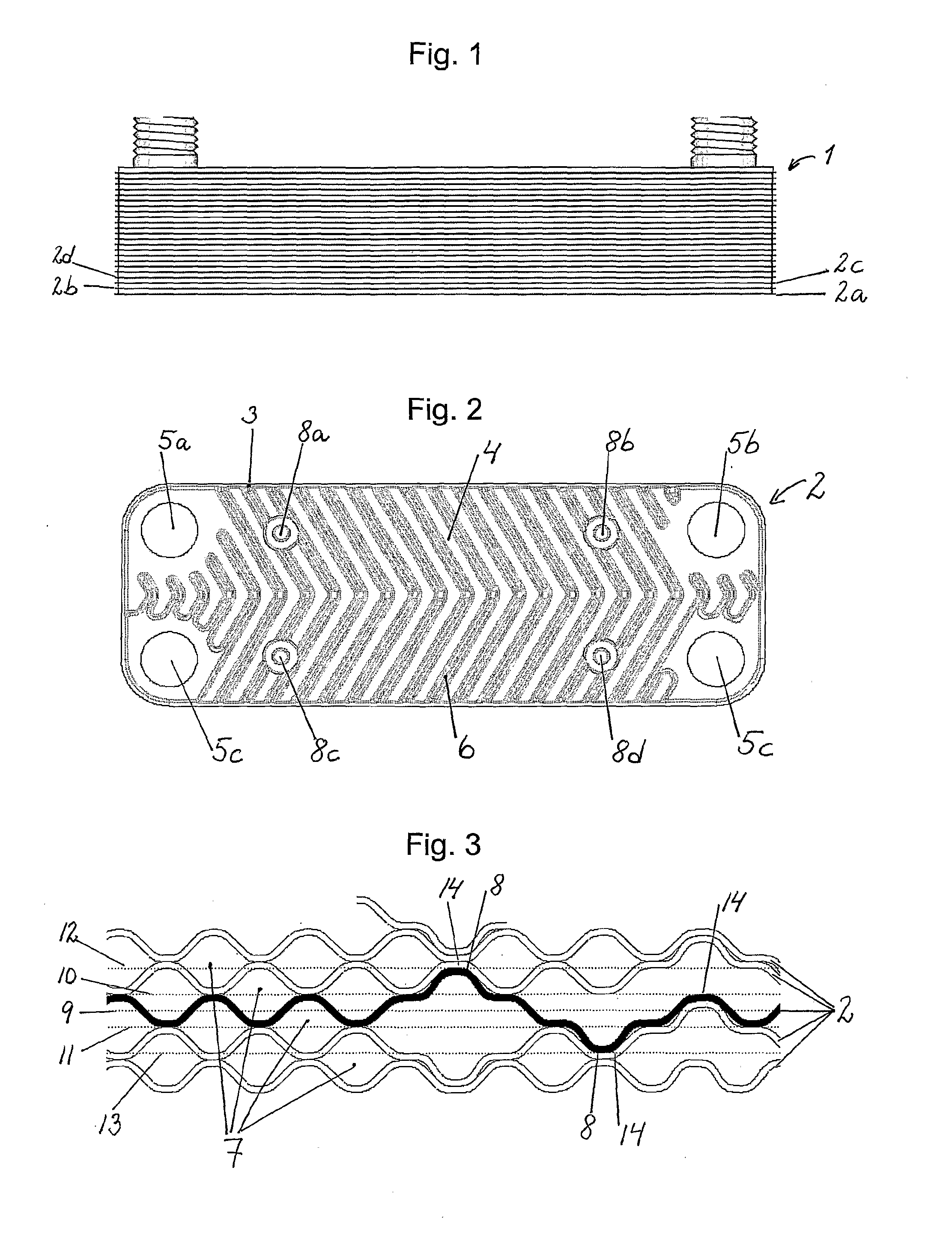

[0027]FIG. 1 depicts a heat exchanger with a plate stack (1) comprising unflanged heat transfer plates stacked on top of one another. In the ensuing text, the expression “heat transfer plate” is synonymous with “plate”. FIG. 2 depicts a plate (2). The plate comprises an edge portion (3) which extends round the periphery of the plate (2). A heat transfer surface (4) is situated within the edge portion (3). At each corner of the plate, a port (5a-d) is provided for inflow and outflow of medium. In the preferred embodiment, the heat transfer plate has a pattern (6) for optimising the heat transfer in the heat exchanger. The pattern (6) comprises crests and valleys, which on mutually adjacent plates abut against one another locally so as to constitute contact points which in a known manner are used for connecting the plates to one another during the soldering together of the heat exchanger. Flow channels (7, see FIG. 3) are formed between mutually adjacent plates (2) in a plate stack (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com