Transport container for hazardous material

a technology for hazardous materials and transportation containers, applied in the field of containers, can solve the problems of wasting cargo space, posing a threat to personnel in the vicinity, and insulating containers, and achieve the effect of less cargo space and efficient return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The disclosed embodiments of the present invention provide a container system for transporting material, such as biohazards, and methods of transporting such materials in a safe and efficient manner. In particular, the system and methods of the present invention allow transportation of hazardous material, while reducing the amount of cargo space used by a transport container when the container is empty.

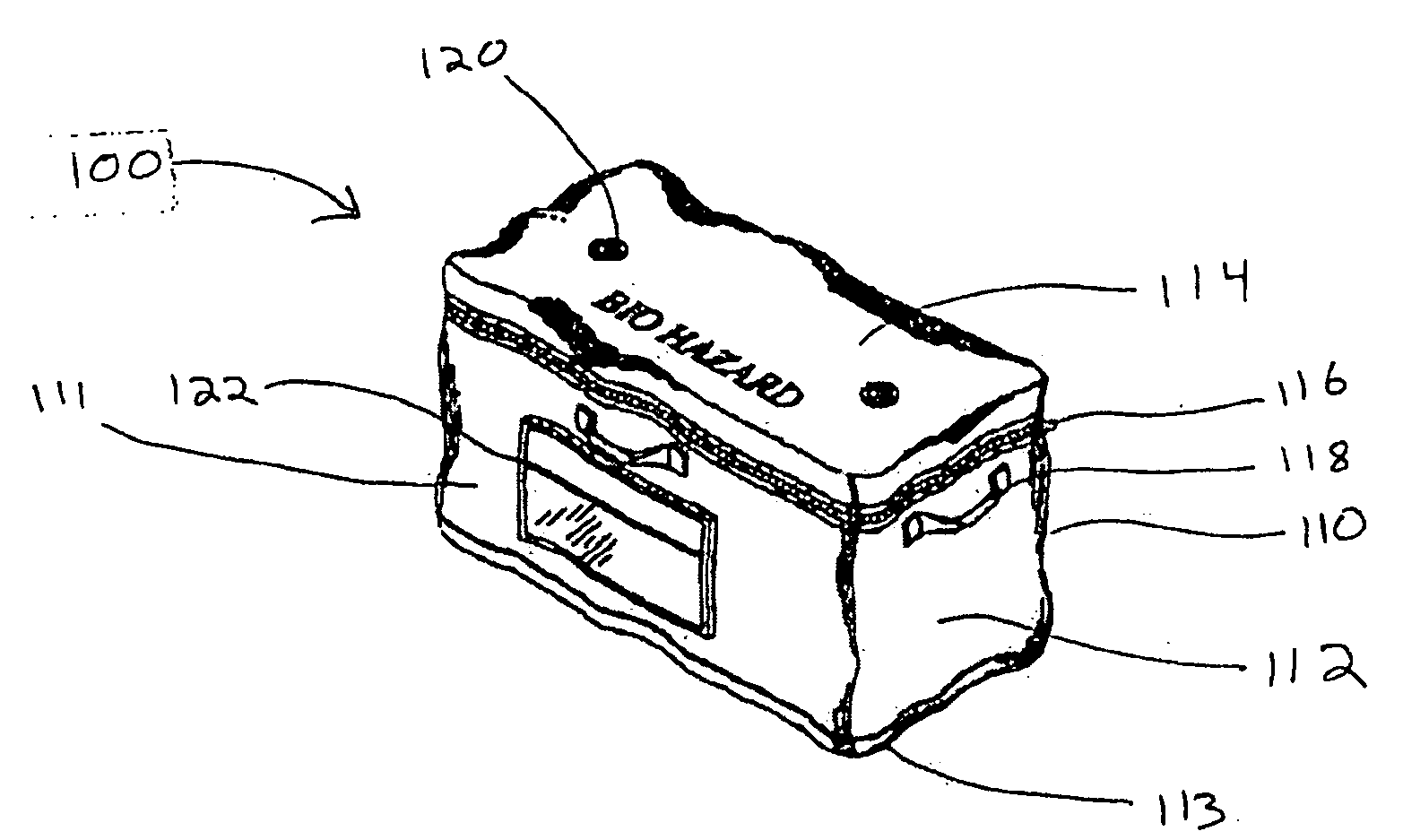

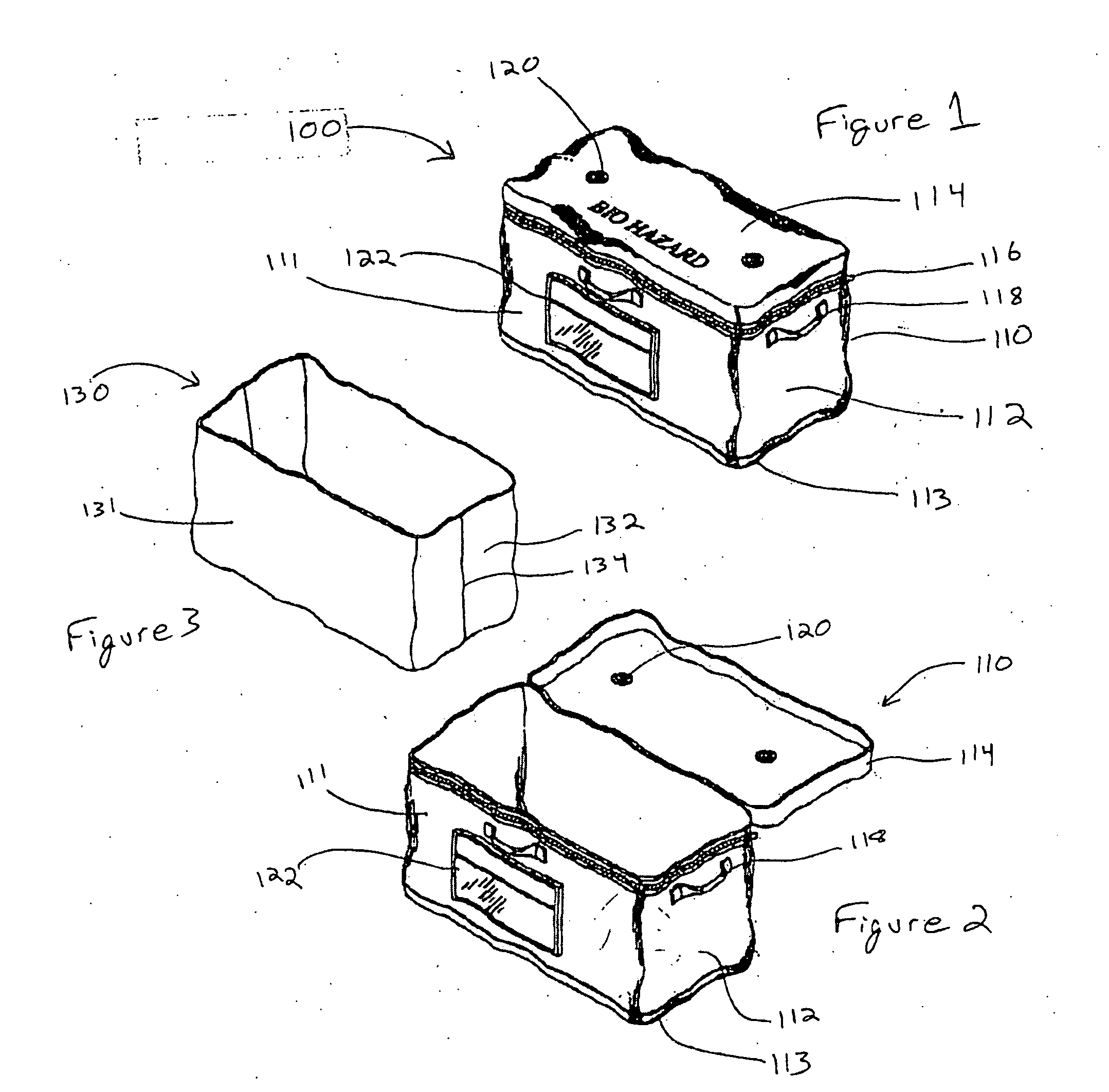

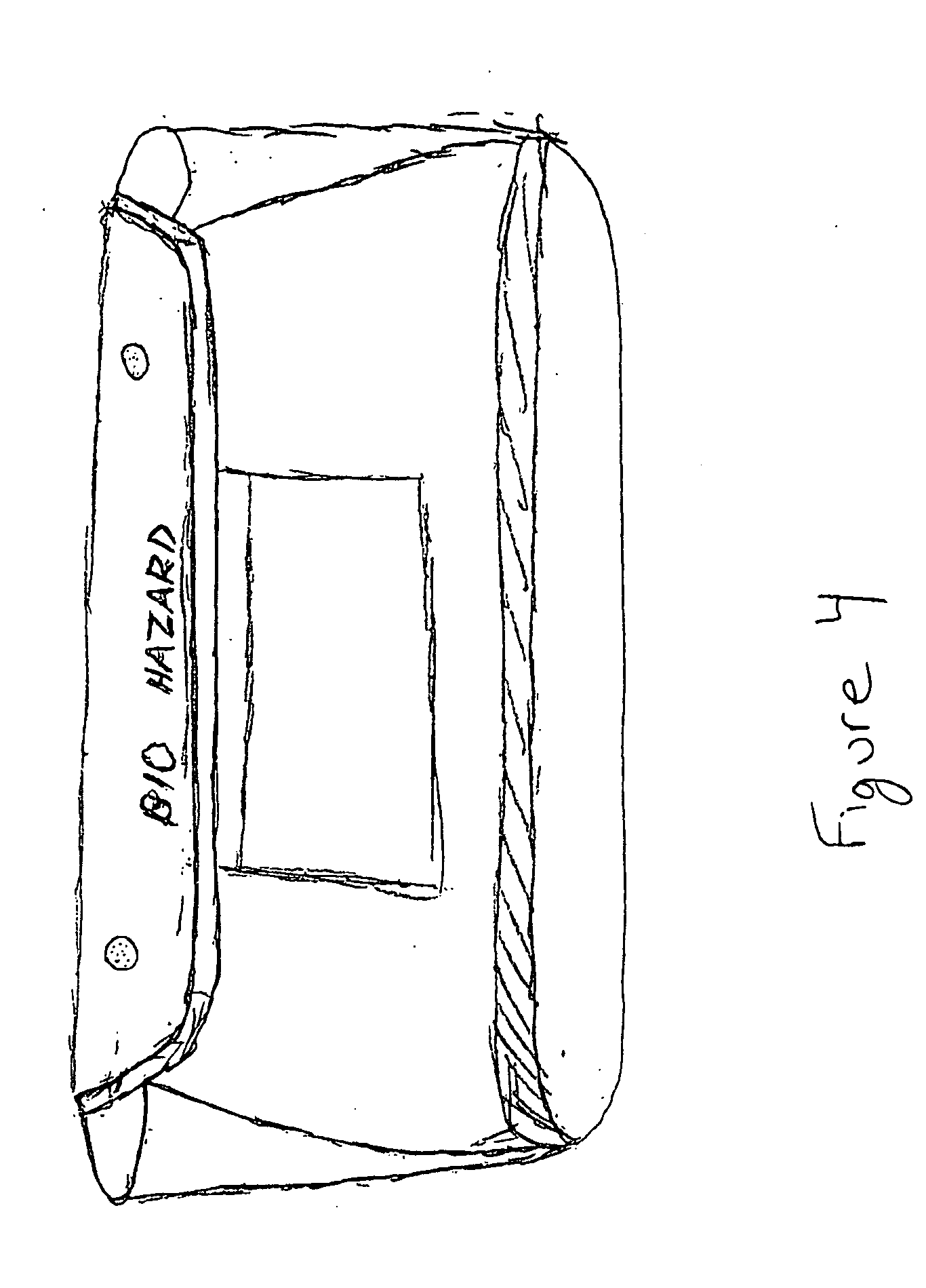

[0034]FIG. 1 illustrates an embodiment of a container system according to the present invention. The container system 100 includes an outer shell 110 that is configured as a rectangular box, as illustrated in FIGS. 1 and 2. The dimensions of the rectangular box may be selected for the desired application. In the preferred embodiment, the rectangular box is 21 inches long, 12 inches wide and 15 inches high. Of course, configurations other than a rectangular box may also be used. For example, a hexagonal box may be used for certain applications.

[0035]The outer shell 110 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com