Cut Flower Preserving Devices and Method

a technology for preserving devices and flowers, applied in the field of flowers, can solve the problems of not being optimal configuration, etc., and achieve the effects of reducing the viability of cut flowers, low humidity, and negatively affecting the light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

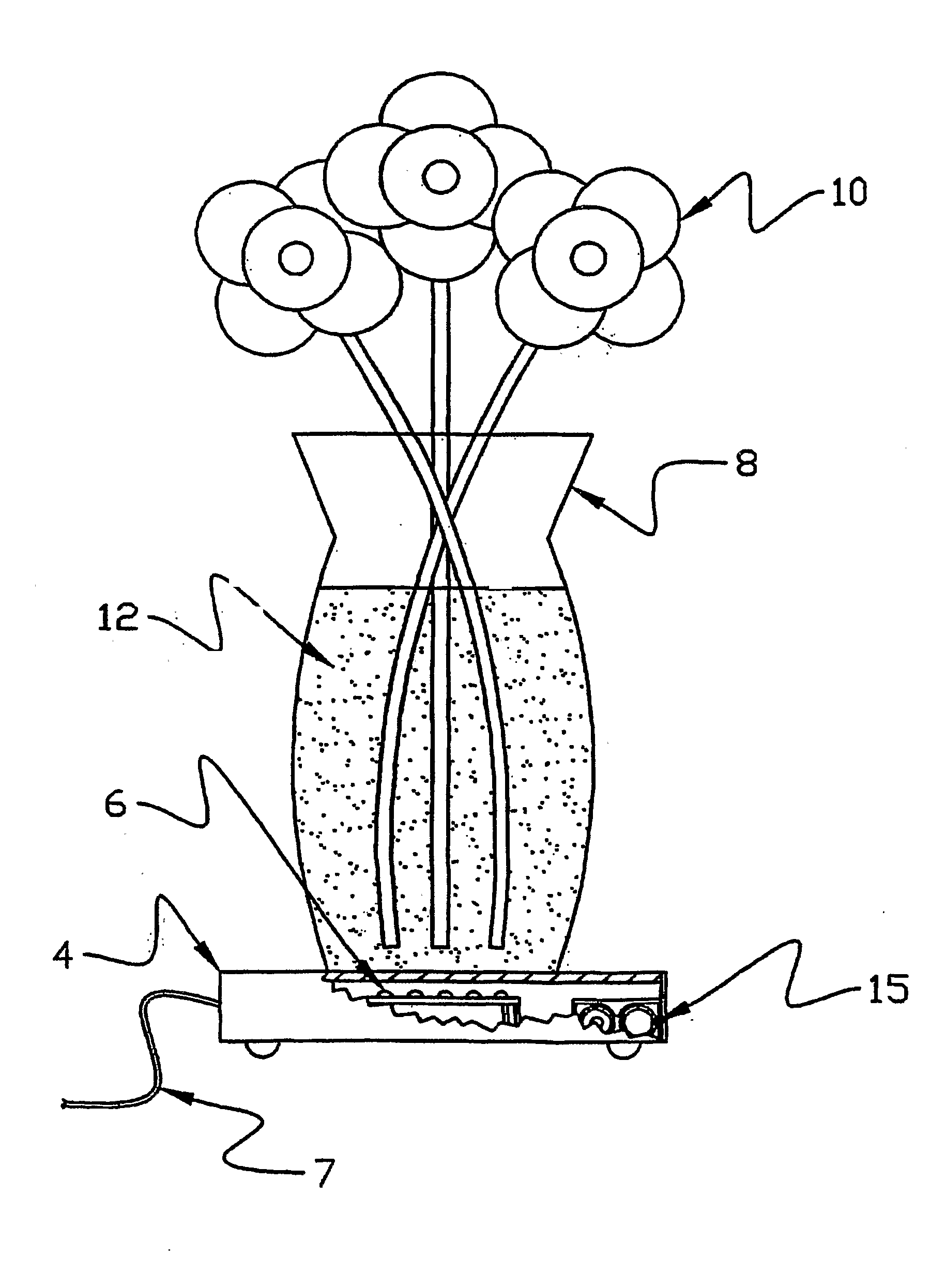

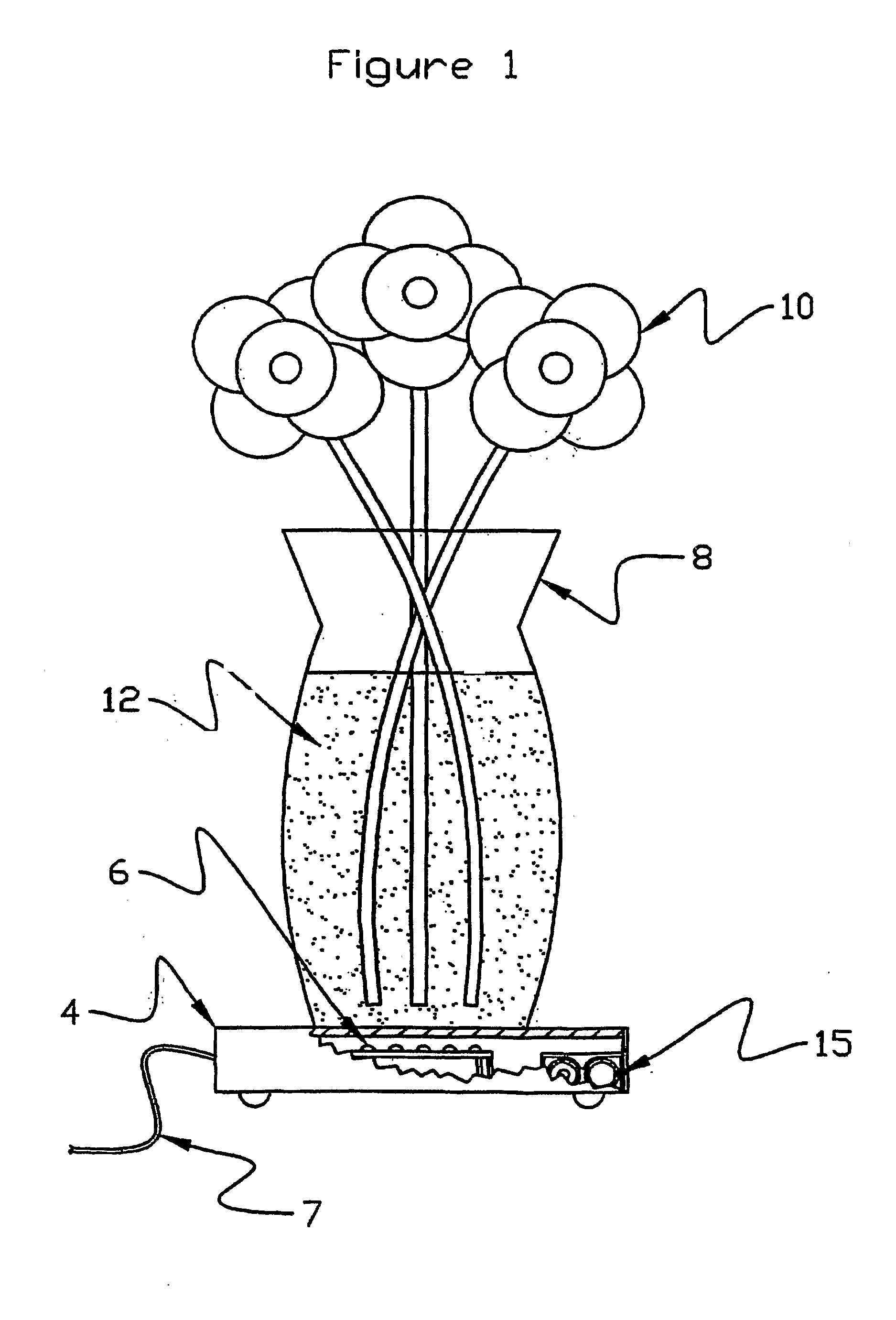

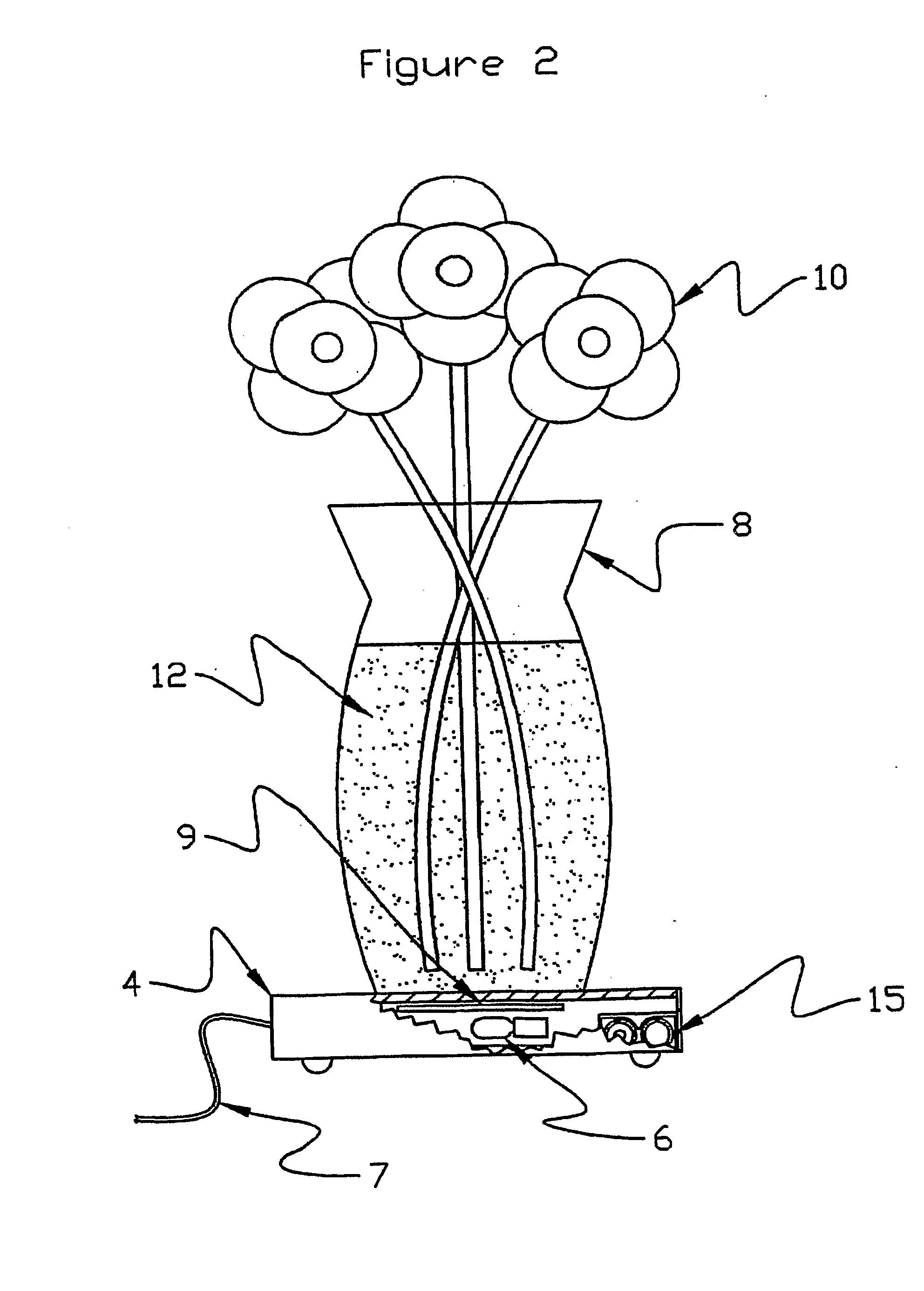

Image

Examples

examples

1. Effect of Wavelength

[0028]The apparatus was generally as shown in FIG. 1. The light source was LED light sticks as described above. Vases used were 4-inch (10.2 cm) diameter cylindrical clear, transparent glass vases. The test flowers were white roses, six in each vase in approximately 8 inches (20 cm) of water. Each light emitting base contained three operating light sticks as described above, except that, of course, the no-light control contained no operating light stick. Light blocks were used to isolate each vase from the others. The room in which the trial was conducted was air conditioned. Room lighting was kept on except on weekends.

[0029]The eight samples included, in addition to the no-light control, seven colors obtained by disengaging selected LEDs as described earlier: red, yellow, magenta and white, for all of which red LEDs were not disengaged, and green, blue and cyan, for all of which the red LED's were disengaged.

[0030]Over a 13-day trial we monitored on a daily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com