Multi-opening, leak-proof packet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

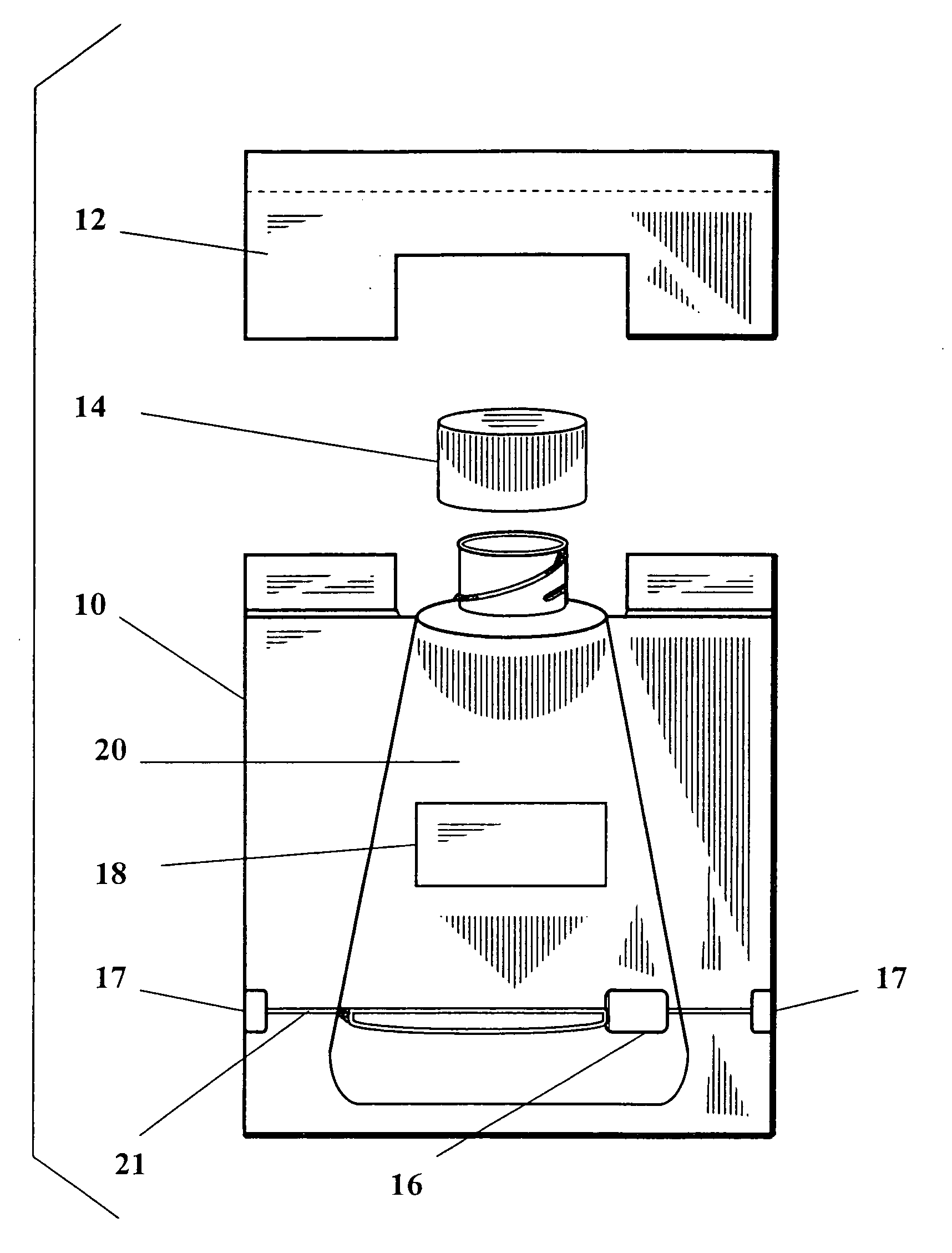

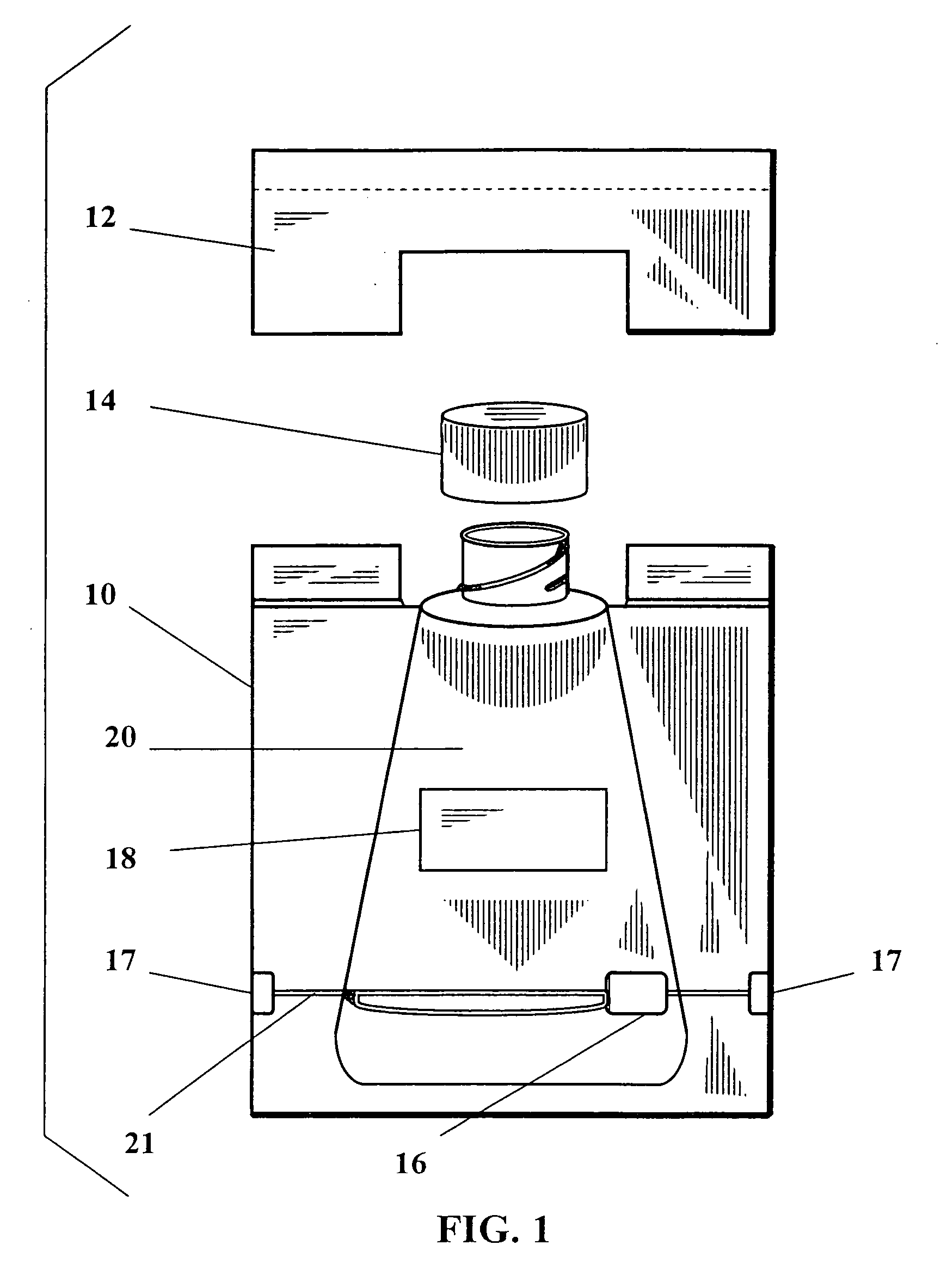

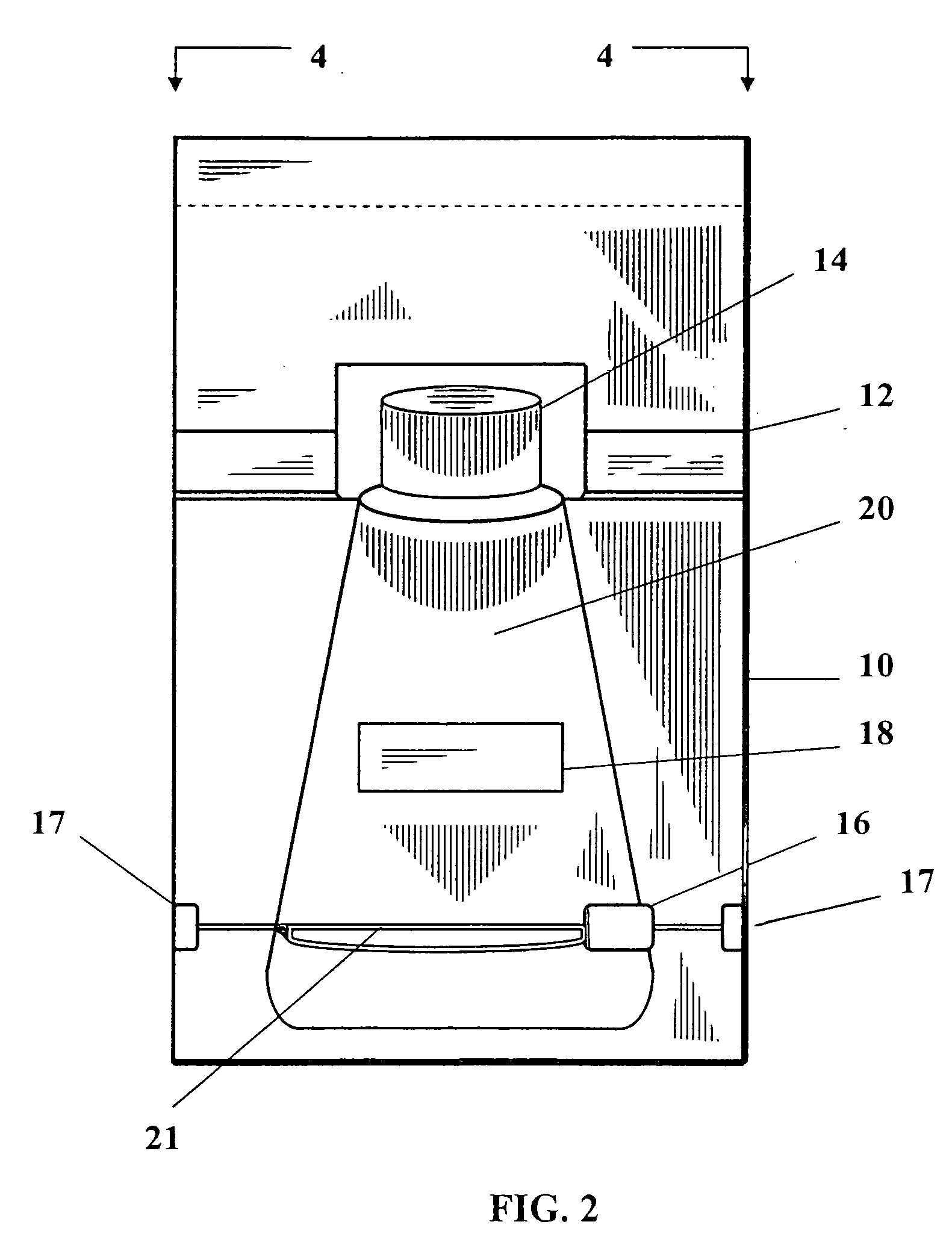

[0069]A typical embodiment of the closure of the present invention is illustrated in FIG. 1 which shows an illustration of the portable, multi-opening, reusable, leak proof liquid dispensing packet 10. Said packet is configured to form a first defined packet volume. The illustration of this packet body 10 shows the flange or header 12 in both ripped and withdrawn position. FIG. 1 further shows a cap 14 withdrawn to reveal a dispensing outlet opening defined in a first or upper surface packet body 10. Packet body 10 is fabricated or configured to include an internal fluid boundary section 20.

[0070]Sliding zipper mechanism tab 16 is illustrated in position to define an input opening in a second surface area of packet body 10, said opening directly communicates with said first defined packet volume. Said tab 16 is configured to move along locking seam 21 extending between end termination clamps 17. Although not shown in great detail, the zipper mechanism tab 16 is understood to be of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com