Metal construction member

a technology of construction members and metal sheets, applied in the direction of girders, joists, trusses, etc., can solve the problems of high cost of manufacture, inability to use in place of standard-sized wall studs, and the specific material used to fabricate construction members, and the shape, thickness and yield strength of these materials have never been optimized with respect to price and performance, and achieve the effect of reducing the thickness dimension of high-yield steel sheets and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]This disclosure of the invention is submitted in furtherance of the constitutional purposes of the U.S. Patent Laws “to promote the progress of science and useful arts” (Article 1, Section 8).

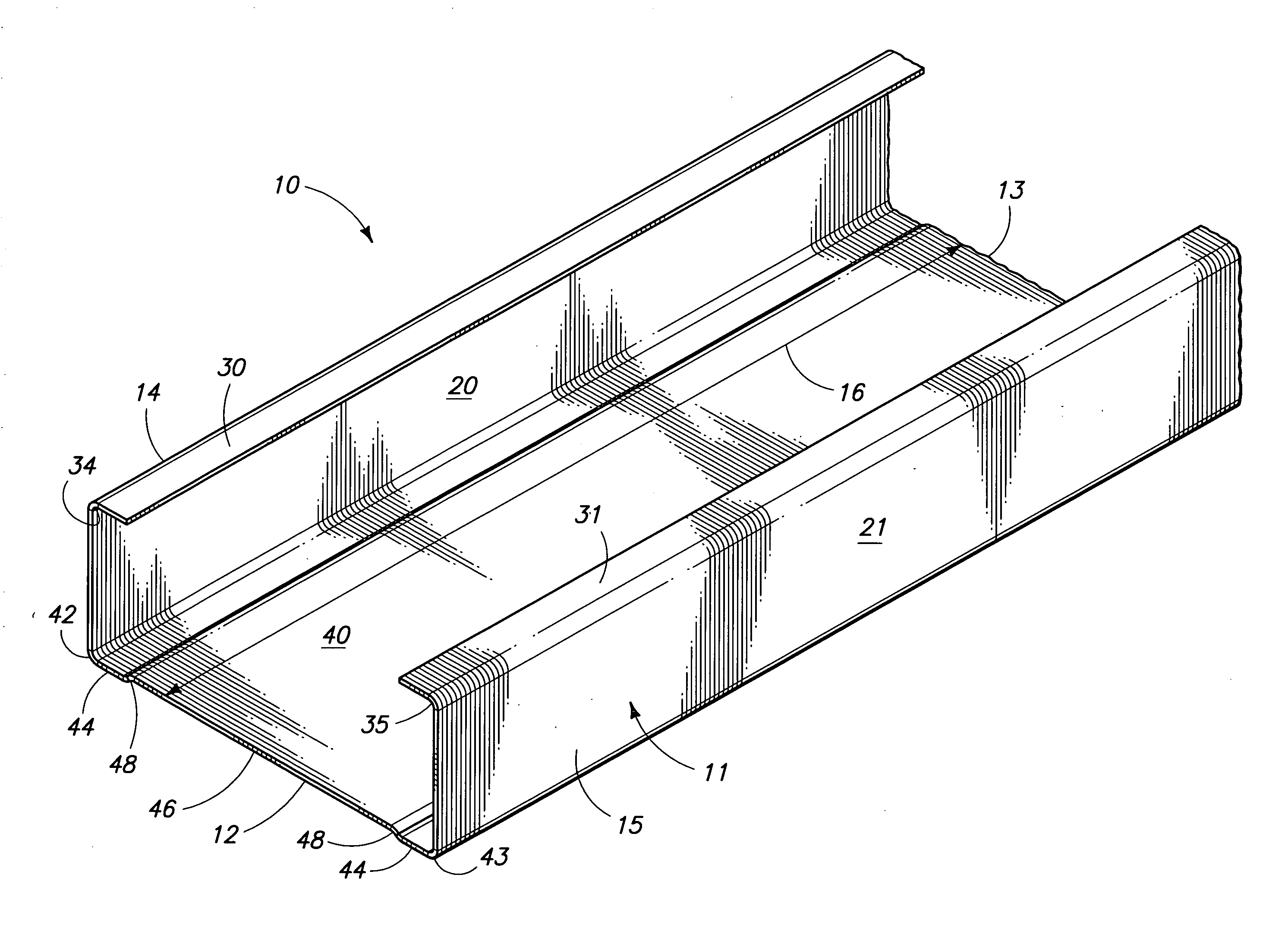

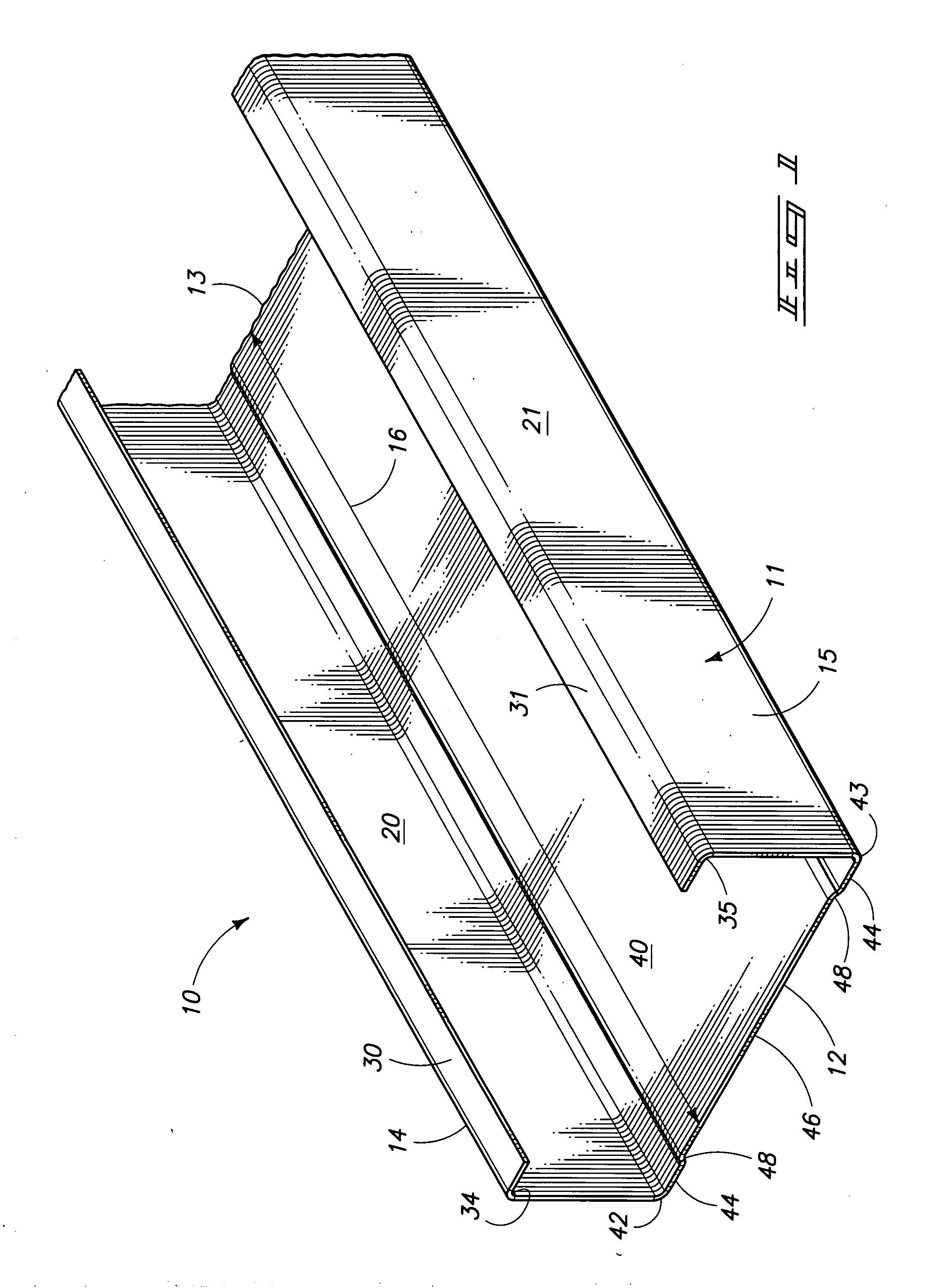

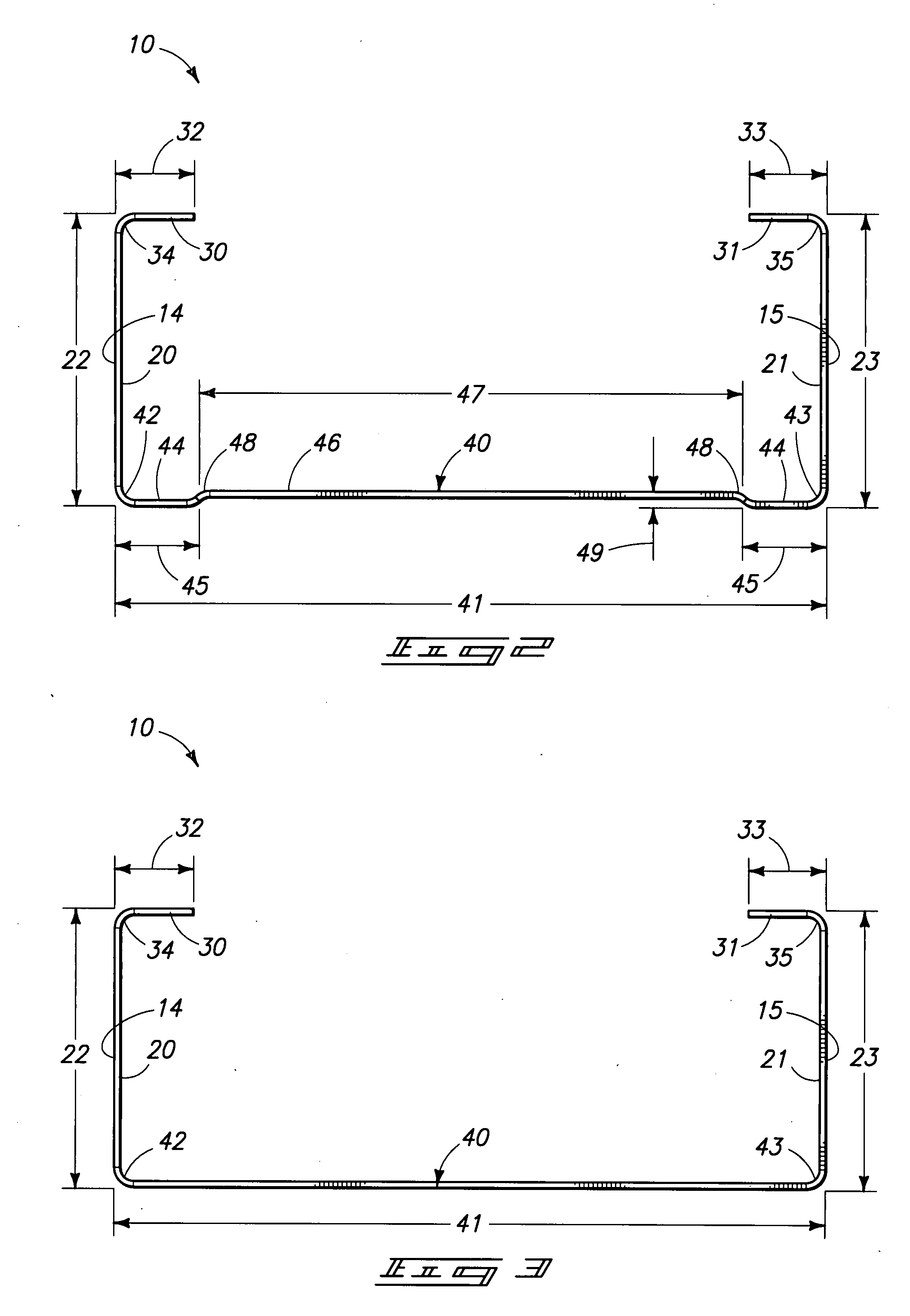

[0014]Referring now to FIGS. 1-3, a construction member which is the subject of the present invention is generally indicated by the numeral 10. The construction member as shown depicts two possible forms of a “C-profile” or “C-shaped” wall stud, although one skilled in the art will recognize that the teachings of the present invention may also be applied to the fabrication of other metal construction members such as trusses, braces, and the like. The construction member 10 may be a wall stud, a floor or ceiling truss or brace, or any other construction member used in a commercial, industrial, or residential construction. Further, the construction member 10 may be used as either a load bearing or a non-load bearing member. In FIGS. 1-3, the construction member 10 is generally shown with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com