Joint Construction, Connector Sleeve, A Coupling Assembly, and a Method for Preparation

a technology for connecting cables and connectors, which is applied in the direction of screw threaded joints, mechanical equipment, etc., can solve the problems of time-consuming and expensive maintenance of individual connector parts, and achieve the effect of reducing manufacturing costs, installation time, and/or inventory concerns associated with maintaining separate inventories of conduit sections and couplers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

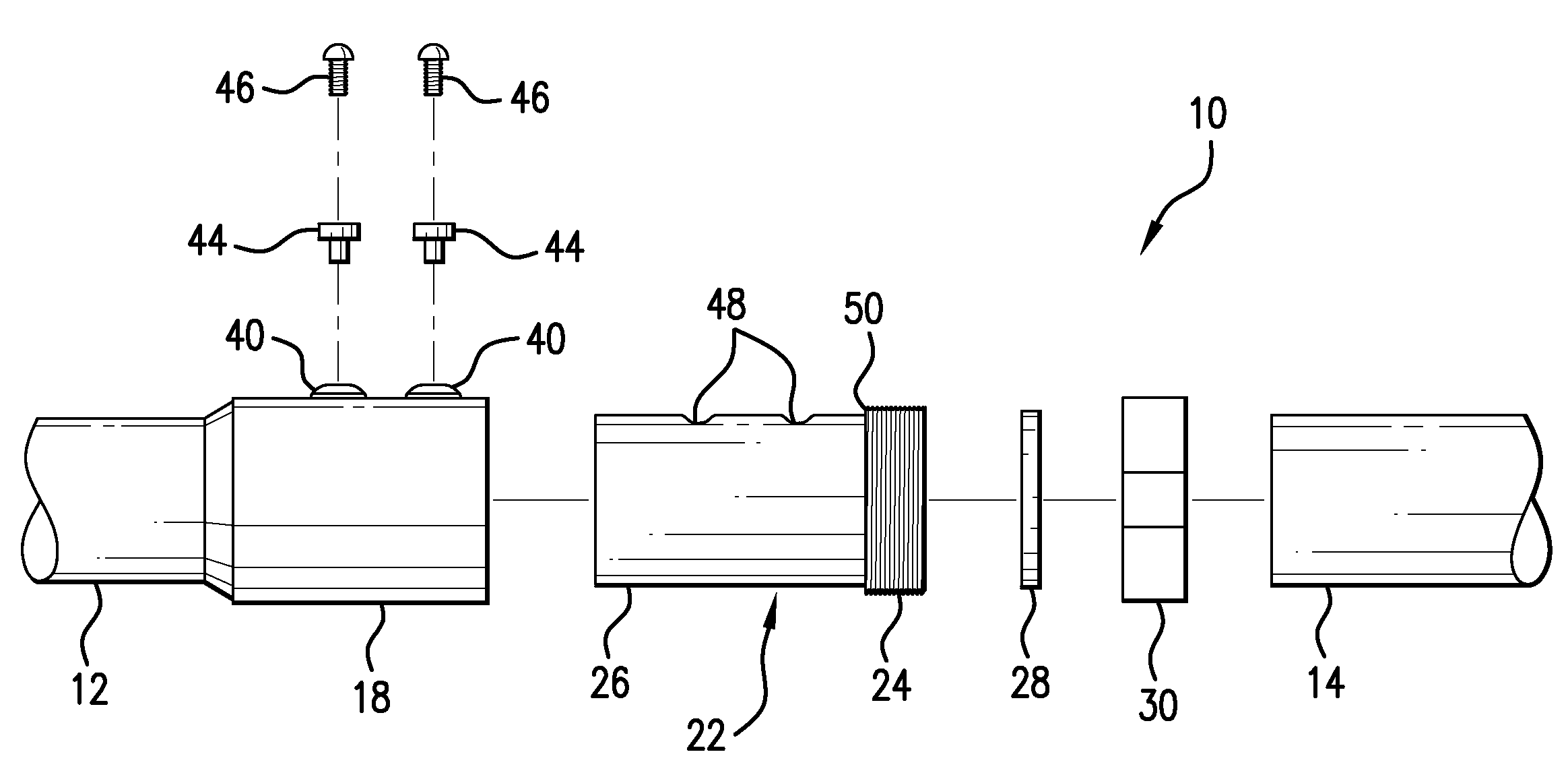

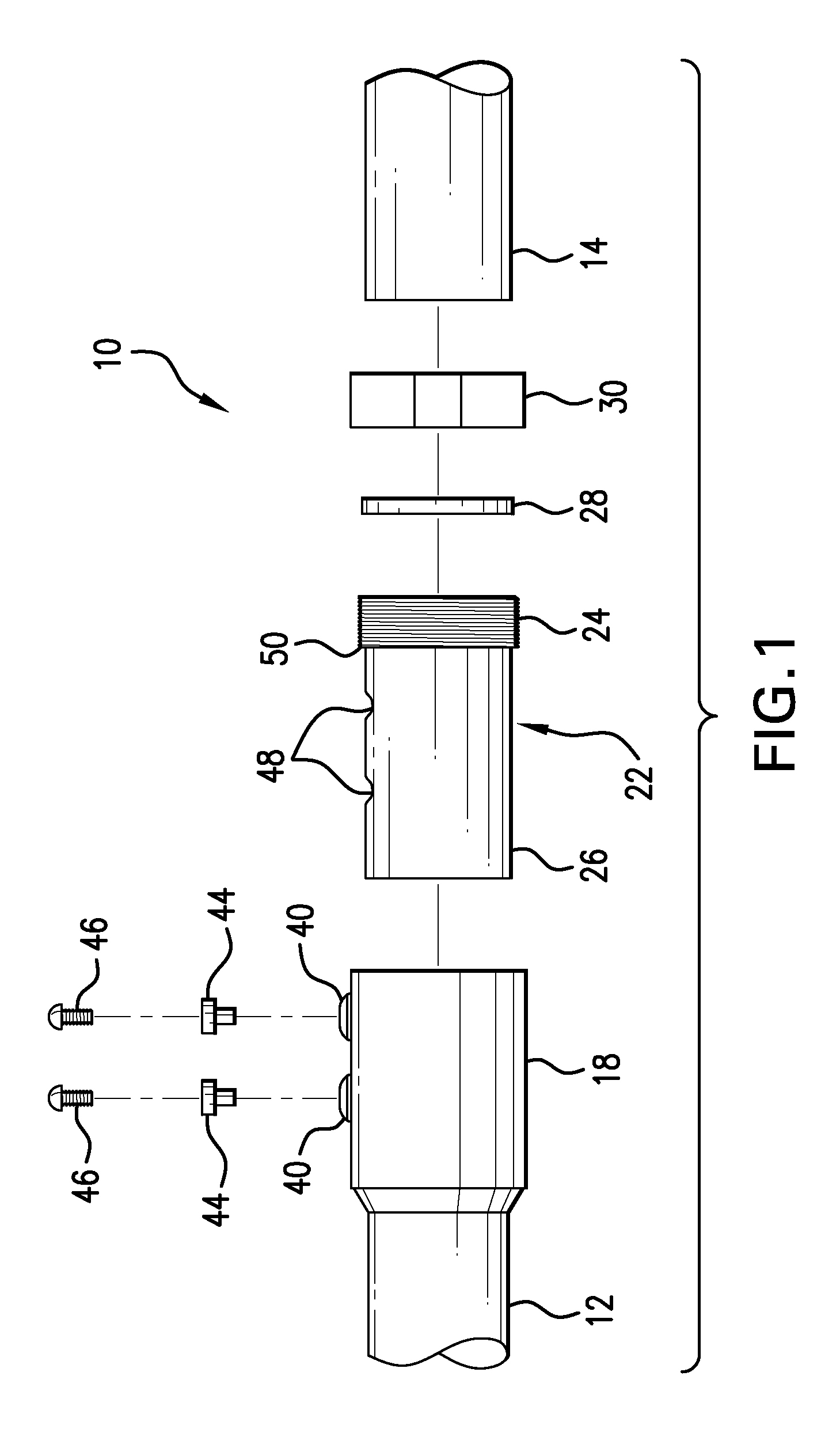

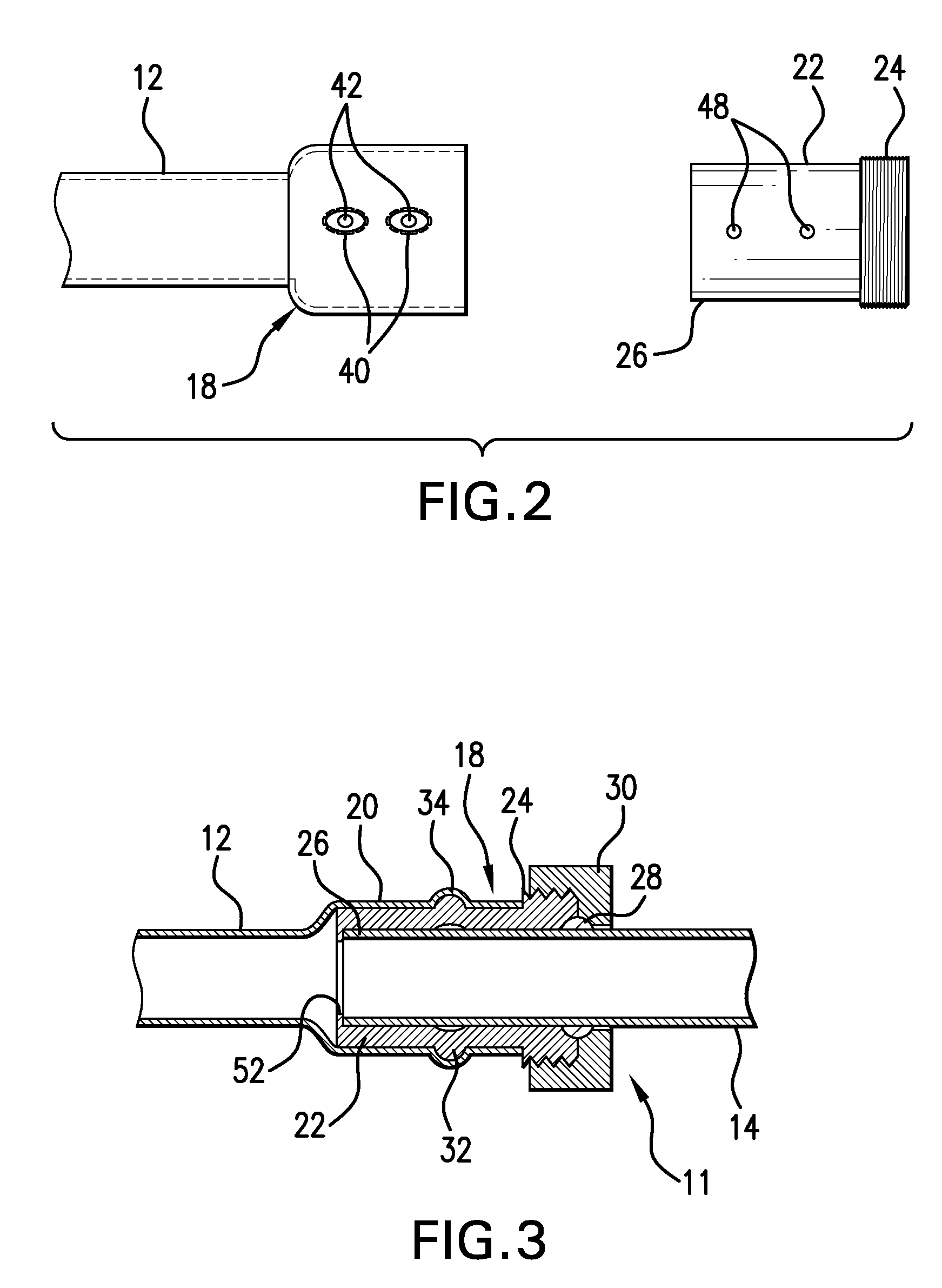

[0018]With reference to the drawing figures, there appears a conduit joint construction 10 (FIG. 1) according to a first embodiment and a conduit joint construction 11 (FIG. 3) for connecting two conduit sections 12, 14 in coaxial, end-to-end fashion. The conduit 12 has at least one receiving end 18. The receiving end 18 is defined by a swaged or bell portion 20. The bell portion 20 has an enlarged diameter with respect to the conduit 34 is designed to receive a connector sleeve 22. The conduit is preferably electrical metallic tubing and may be formed of steel, aluminum or aluminum alloy, or other metal or metal alloy. Other conduit materials are also contemplated, such as PCV and other plastics.

[0019]The connector sleeve 22 has an externally threaded end 24 and an insertion end 26. Furthermore, the connector sleeve 22 defines an axial channel or bore having an internal diameter sized to receive an end of the second conduit 14. The insertion end 26 of the connector sleeve 22 can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com