High-pressure pneumatic apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

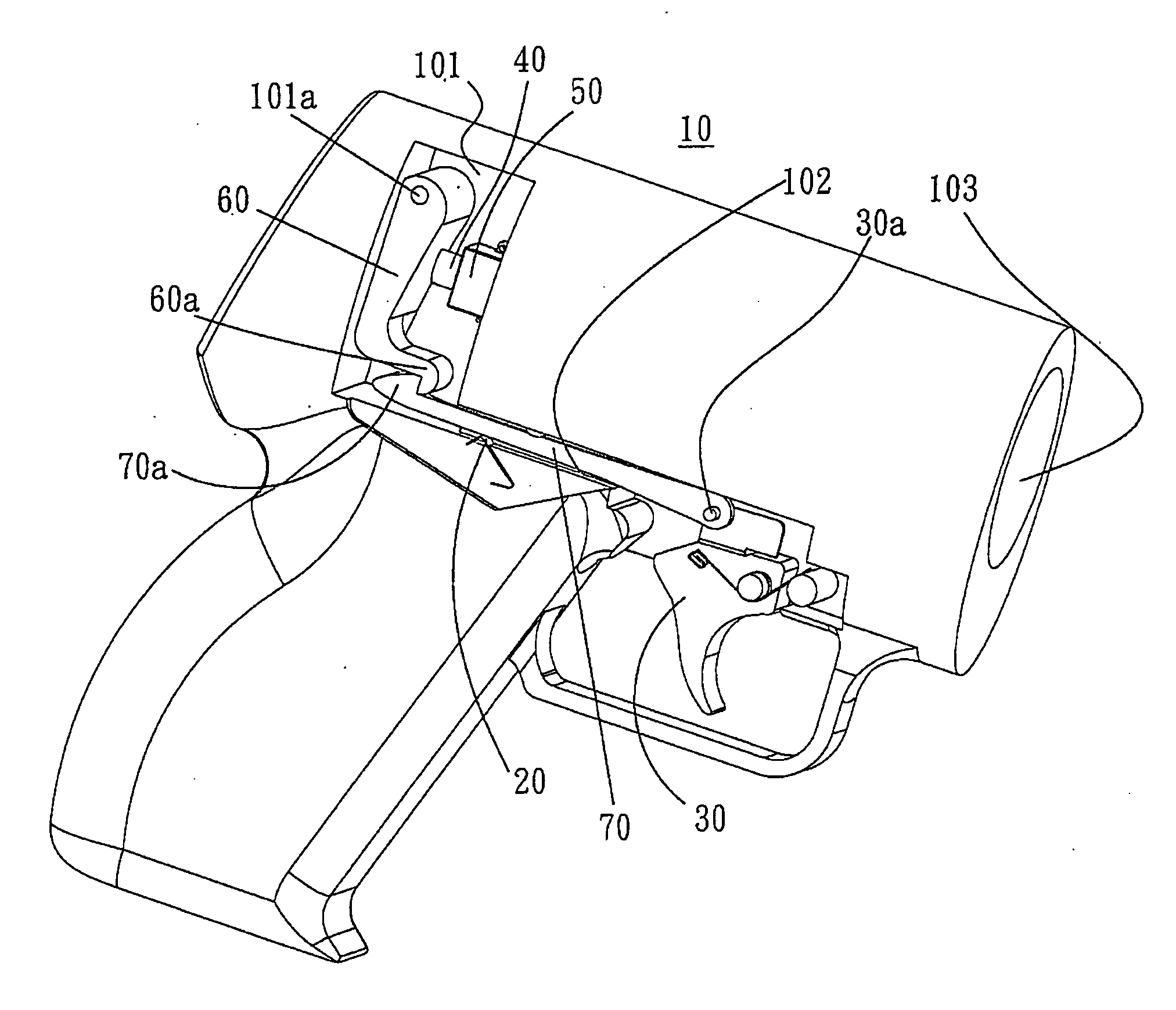

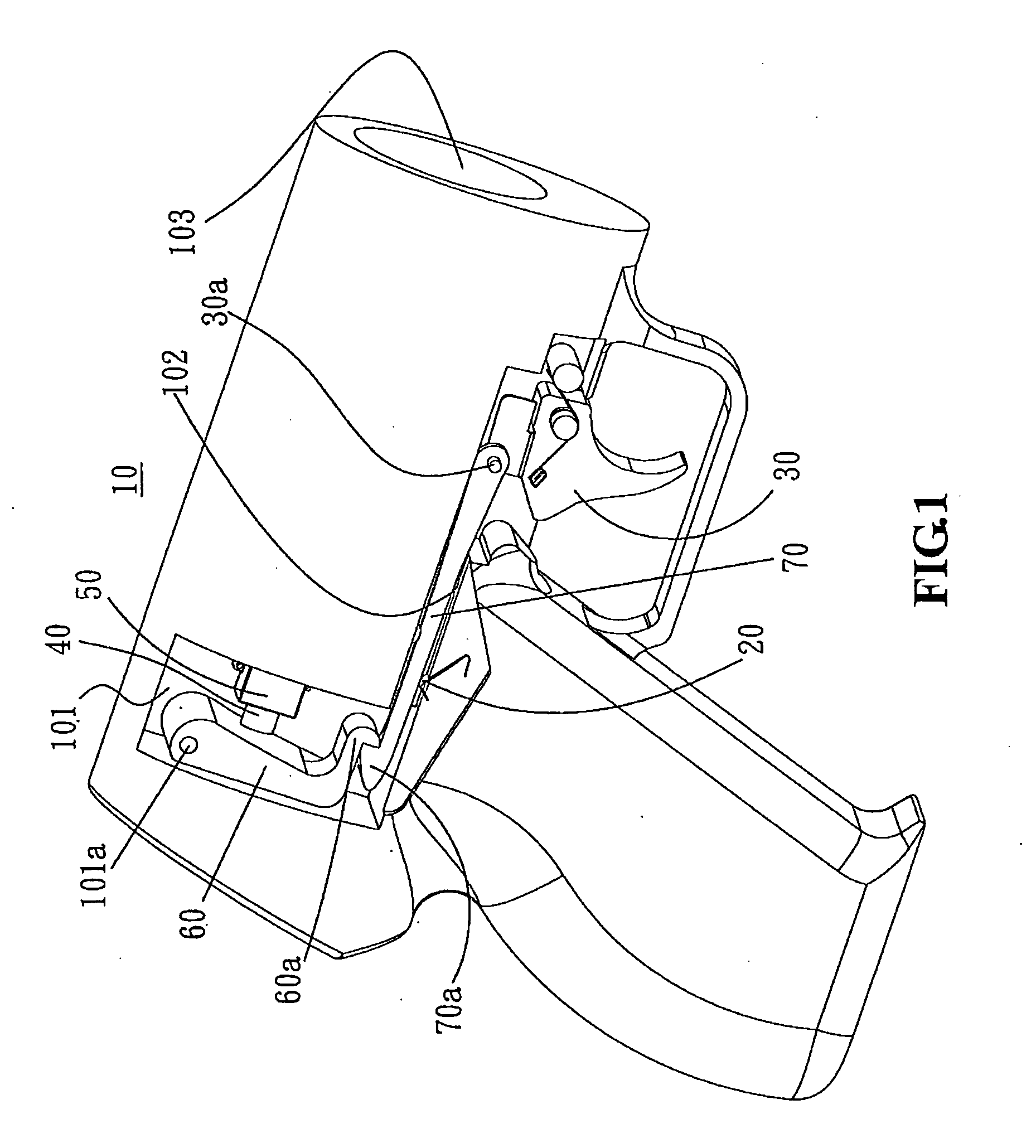

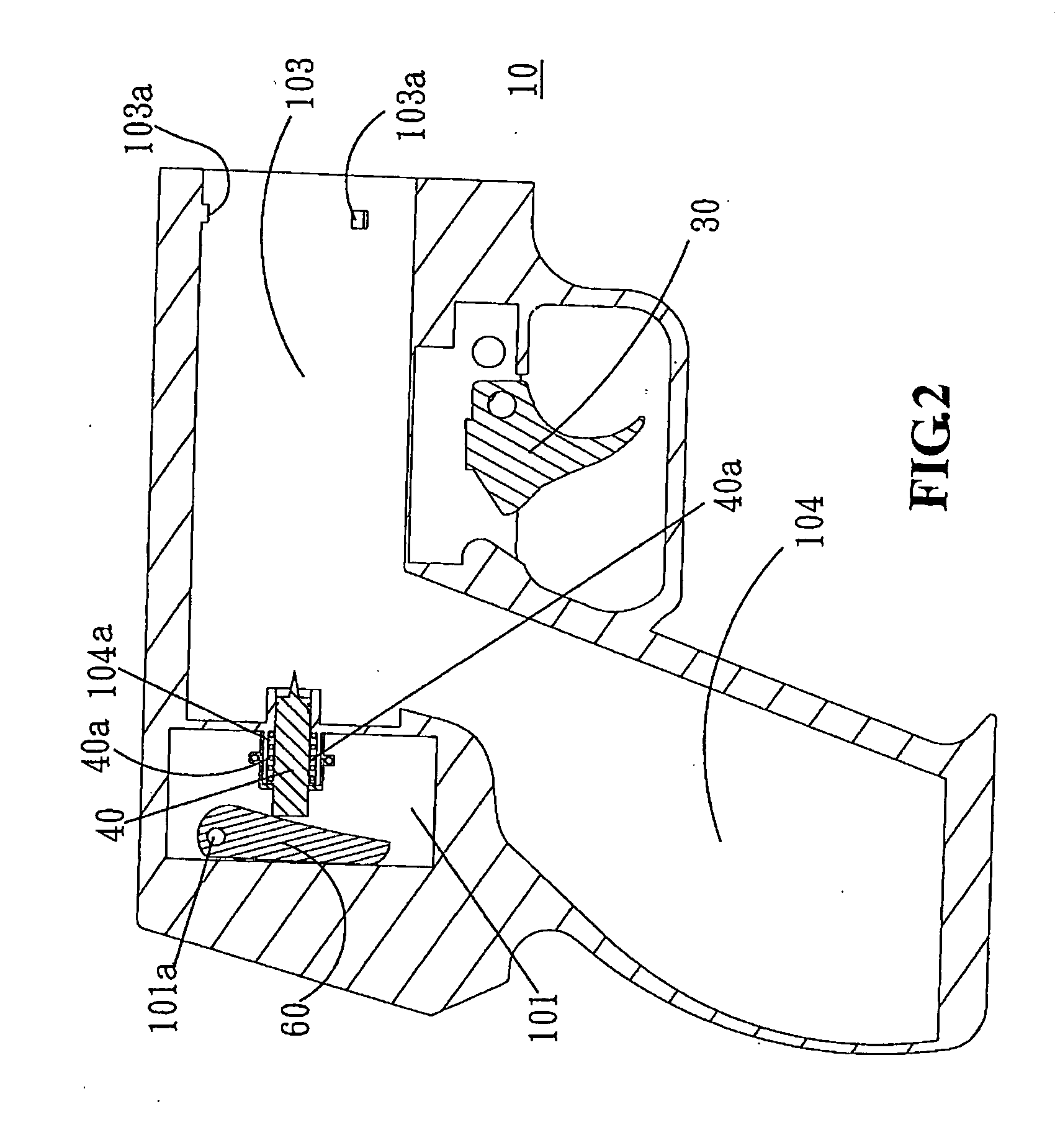

[0020]An improved high-pressure pneumatic apparatus comprises an actuation gun 10, a gas-pressure device 80, and a recessed disk 95.

[0021]Referring to FIGS. 1 and 2, the actuation gun 10 mainly includes a recess 101 and a forwardly extended shaft slot 102 in communication with the recess 101. A tension spring 20 is inserted in a bottom of the shaft slot 102, slightly protruding out of the shaft slot 102. In addition, a trigger 30 is disposed at a distal end of the shaft slot 102. Referring to FIG. 2, the actuation gun 10 includes a barrel gas chamber 103 at a front portion thereof. The barrel gas chamber 103 is in communication with a handle internal chamber 104. A hole in communication with the recess 101 is defined at a rear of the barrel gas chamber 103. A tube protrudes from an edge of the hole to form a tube slot 104a. A strike pin 40 and a spring 40a can be inserted through the tube slot 104a, and a cover 50 having a through hole can cover the tube slot 104a. Besides, a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com