Cover assemblies for covering objects

a technology for covering objects and assemblies, applied in the field of covering assemblies, can solve the problems of dirt being transferred from the cover to the object being covered, cumbersome and unsightly, and difficult to fit on the known cover, and achieve the effect of convenient and rapid deployment of the covering member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

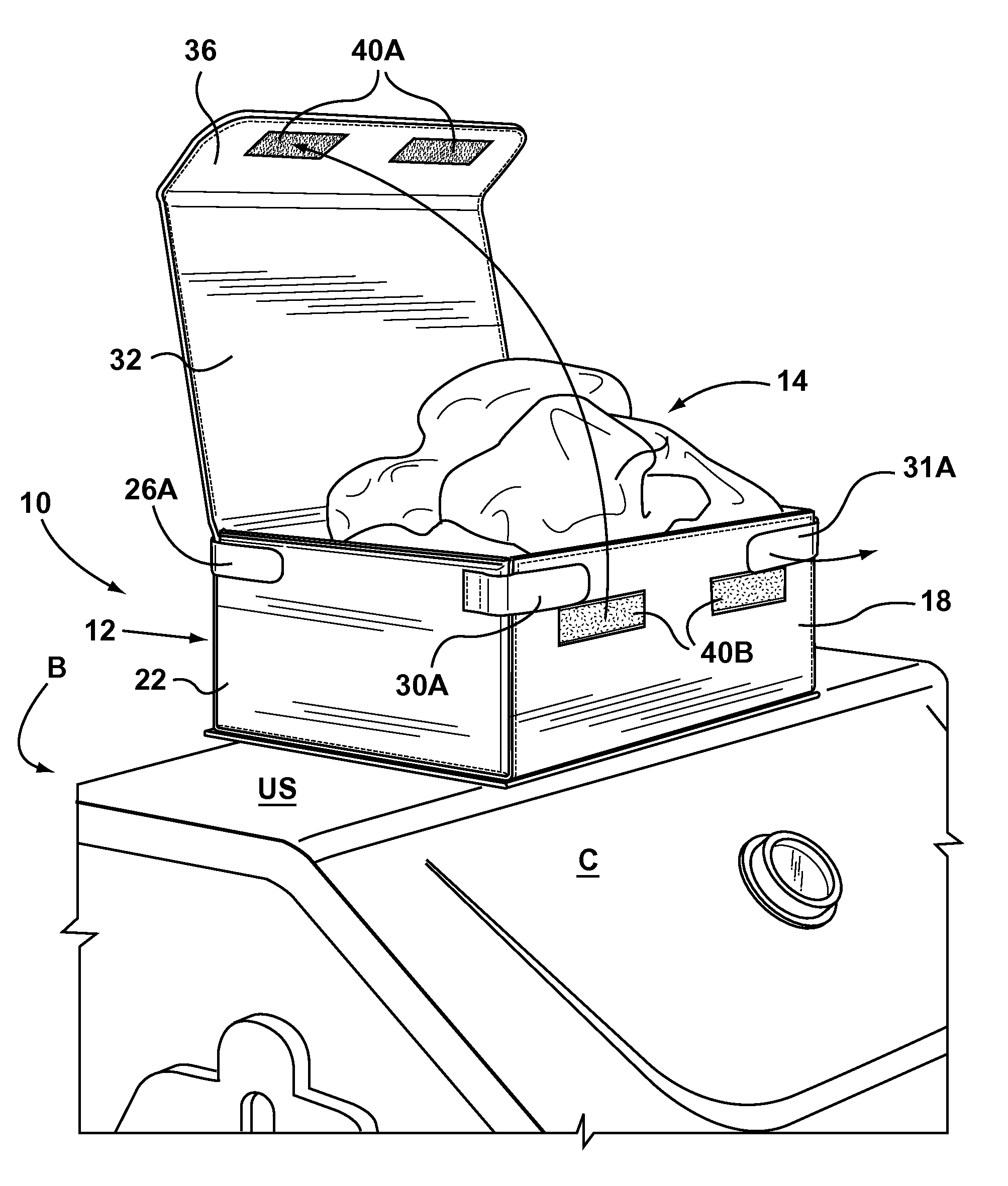

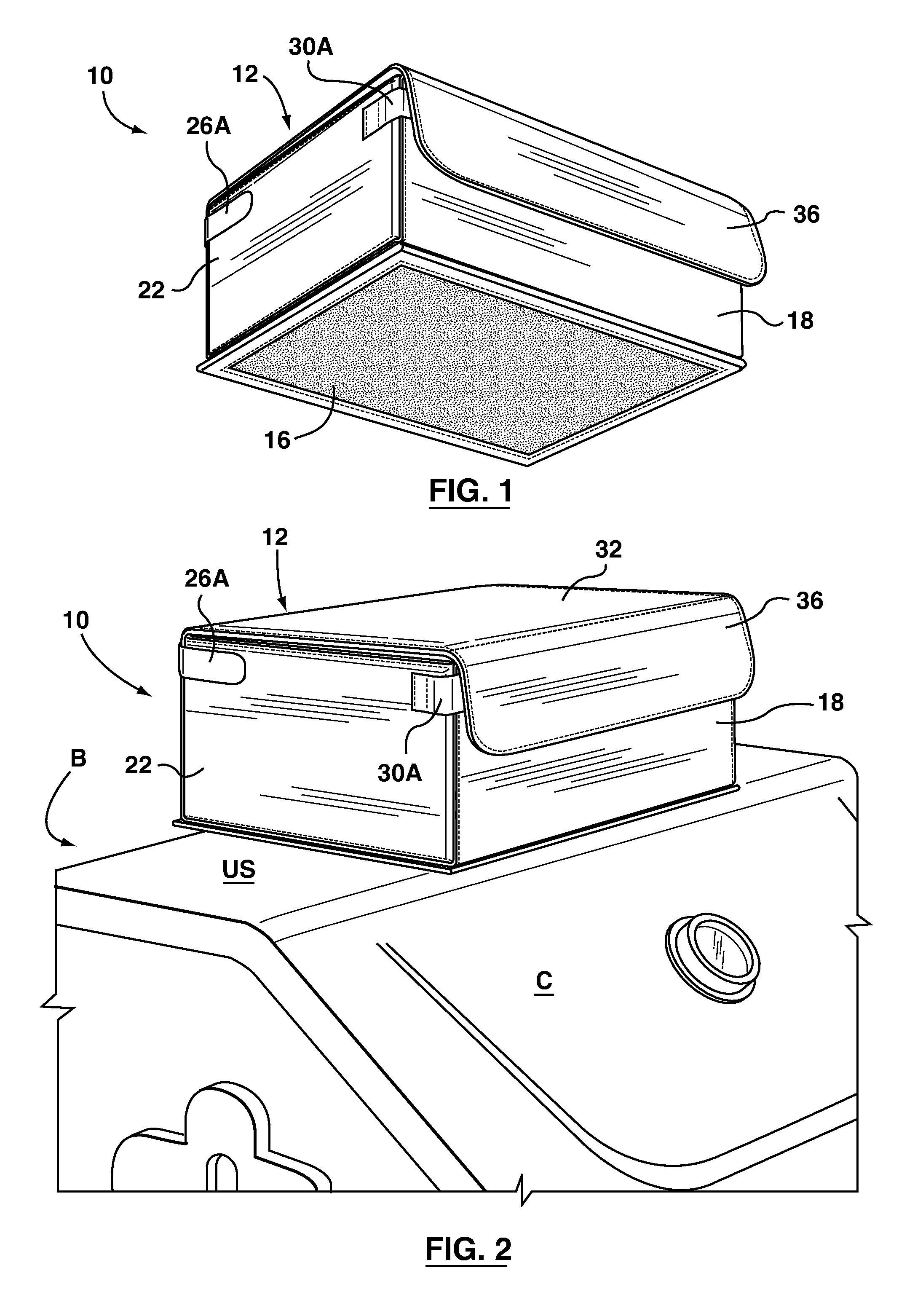

first embodiment

[0136]In another embodiment (not shown), the walls may be held in the erected configuration by an actuating member in the form of a cord extending around the upper ends of the walls and passing through apertures therein. The cord may be provided with a slider which retains the walls in the erected configuration, and can be slid back to permit the container walls to fall outwardly to the collapsed configuration to expose the covering member 14. Conversely, to return the container to the erected configuration, a user would pull the cord and slide the slider along the cord to abut the front wall of the container. A lid similar to lid 32 in the first embodiment may be provided. An example of such an arrangement is shown in U.S. Patent Application Publication No. 20070283946 A1, which is co-owned by the assignee hereof.

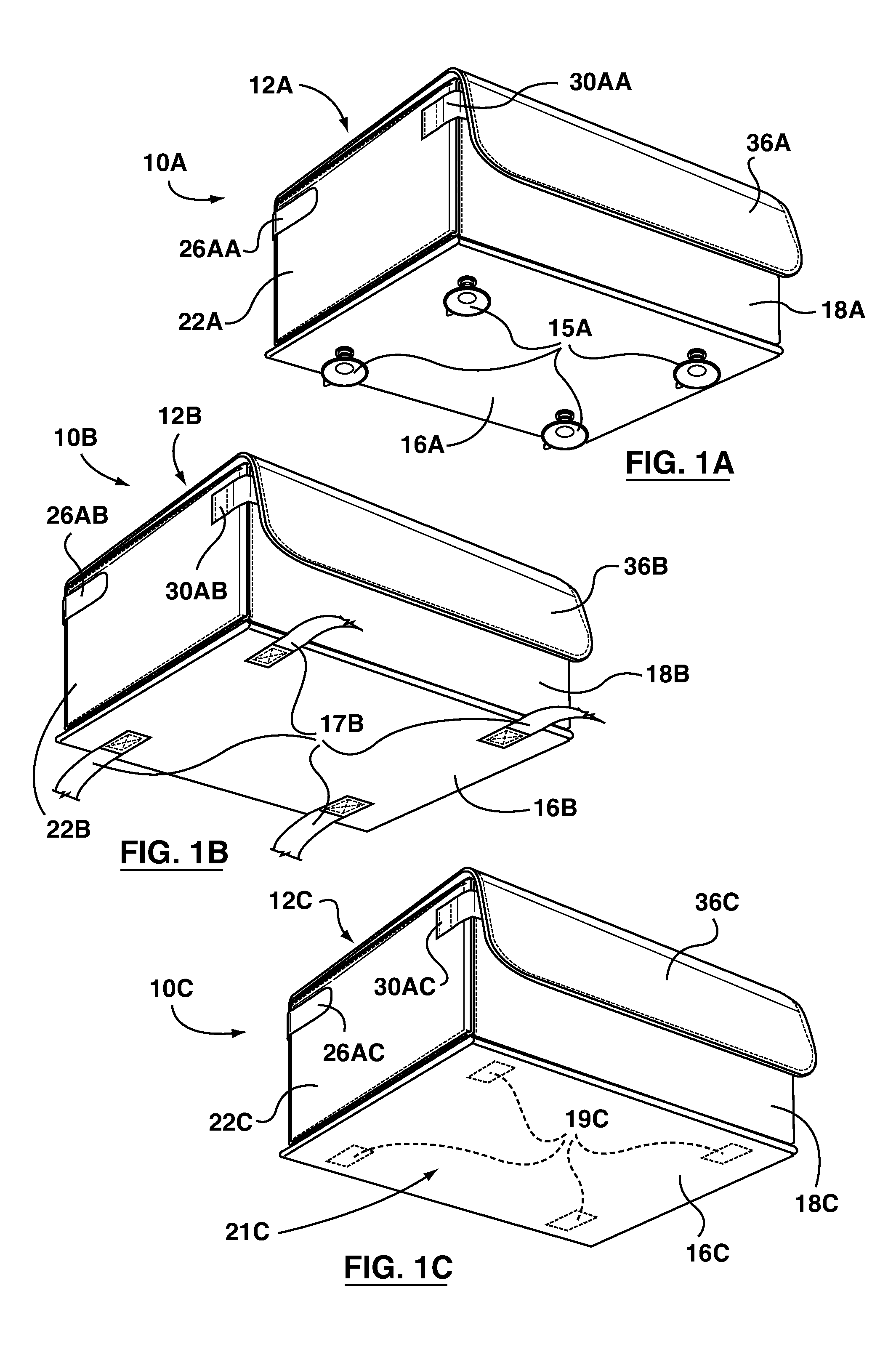

[0137]In the exemplary embodiments 10, 10A, 10B and 10C so far described, the respective container 12, 12A, 12B, 12C has taken the form of a rectangular parallelepiped. Ot...

embodiment 1900

[0139]The container 1902 is a clamshell container, comprising a first clamshell portion 1908 and a second clamshell portion 1910 pivotingly secured to one another at respective inner edges 1912, 1914 thereof. In the illustrated embodiment 1900, the first clamshell portion 1908 and the second clamshell portion 1910 are made from a flexible fabric material, and are pivotingly secured to one another by way of a living hinge 1916 (FIG. 20). The closed configuration of the clamshell container 1902 is defined by the first clamshell portion 1908 and the second clamshell portion 1910 being in facing relation to one another as shown as shown in FIGS. 18 and 19; this closed configuration serves as a containment configuration for containing the covering member 2104. By pivoting the clamshell portions 1908, 1910 away from one another about the living hinge 1916, the container 1902 can be moved into an open configuration to permit deployment of the covering member 2104. The container includes a ...

third embodiment

[0187]In FIGS. 30E and 30F, a cover assembly for covering a notional watercraft 3050 according to an aspect of the present invention, is indicated generally at 3000E. The cover assembly 3000E comprises a container in the form of an upright bag 3002E and a covering member 3004E. The covering member 3004E has a size and shape corresponding to those of the notional watercraft 3050 to be covered, but aside from this difference is substantially identical to the cover assembly 2900E. The predetermined position of the covering member 3004E, which is secured to the container 3002E, is the portion that will cover the seat of the notional watercraft 3050, and the predetermined position of the notional watercraft 3050 is the seat thereof. In FIG. 30E, the cover assembly 3000E is shown anchored on the seat of the notional watercraft 3050 with the upright bag 3002E in the closed configuration and thereby containing the covering member 3004E. FIG. 30D shows the cover assembly 3000E with the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com