Weaving Machine Comprising Pneumatic Weft Insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

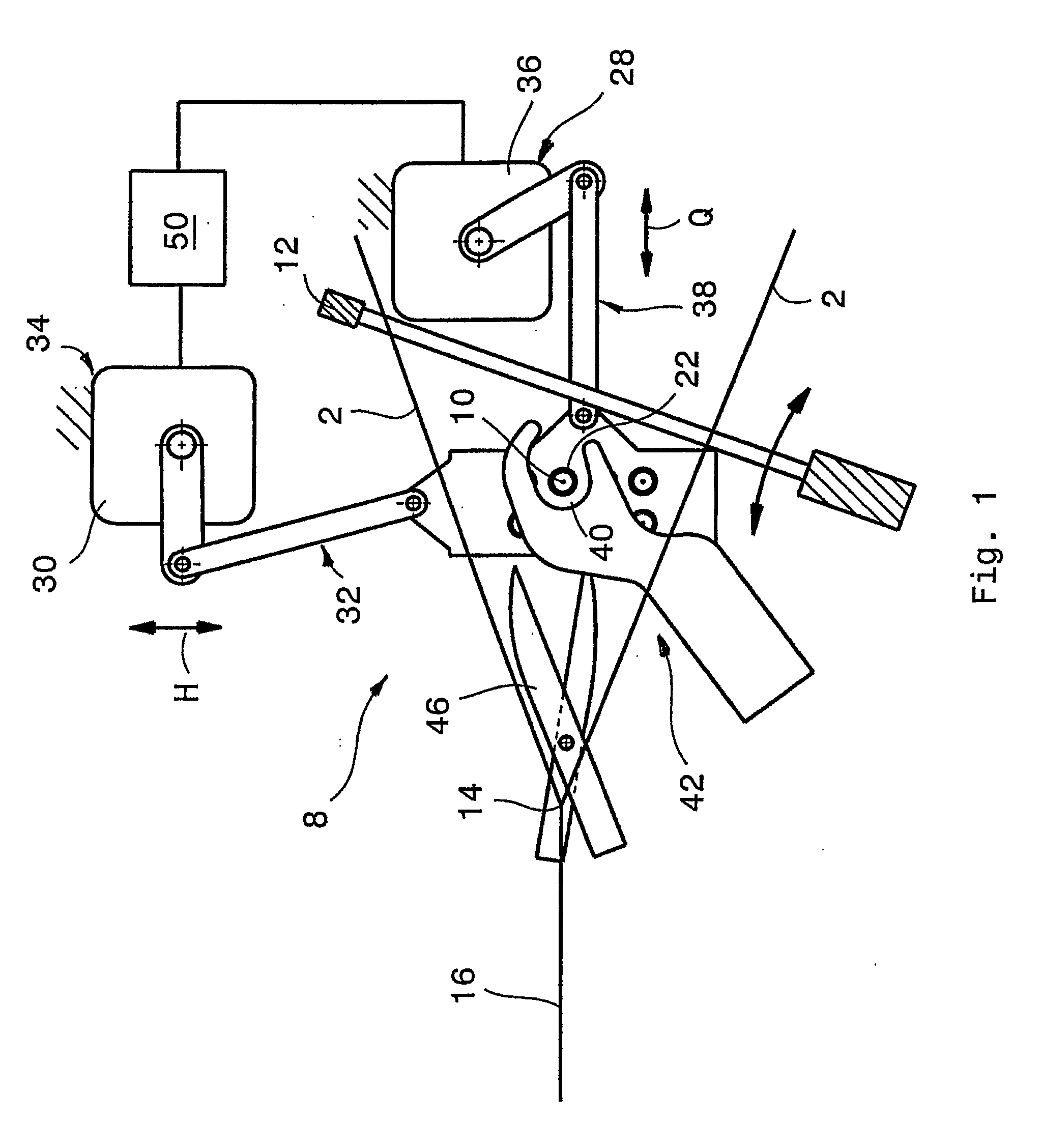

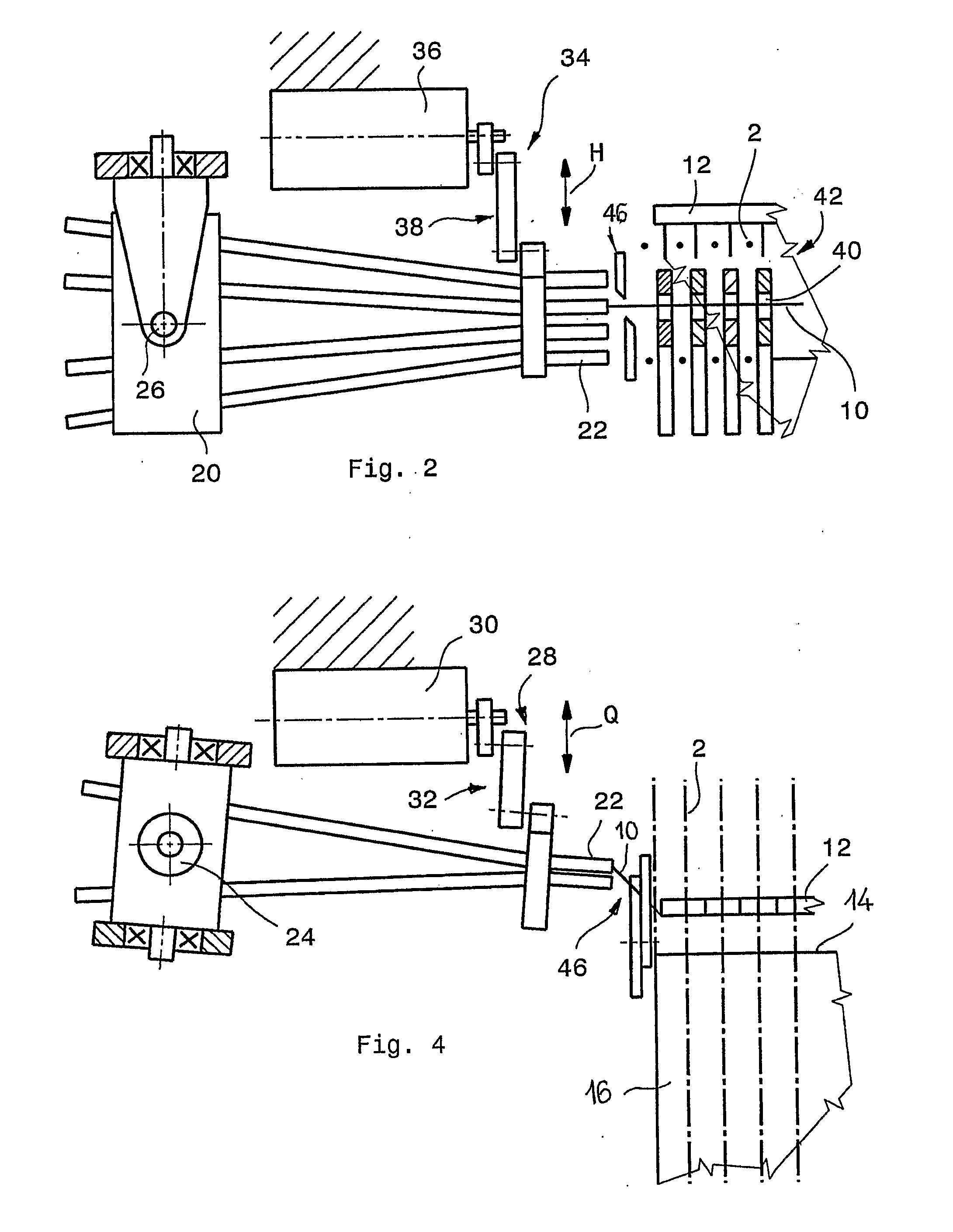

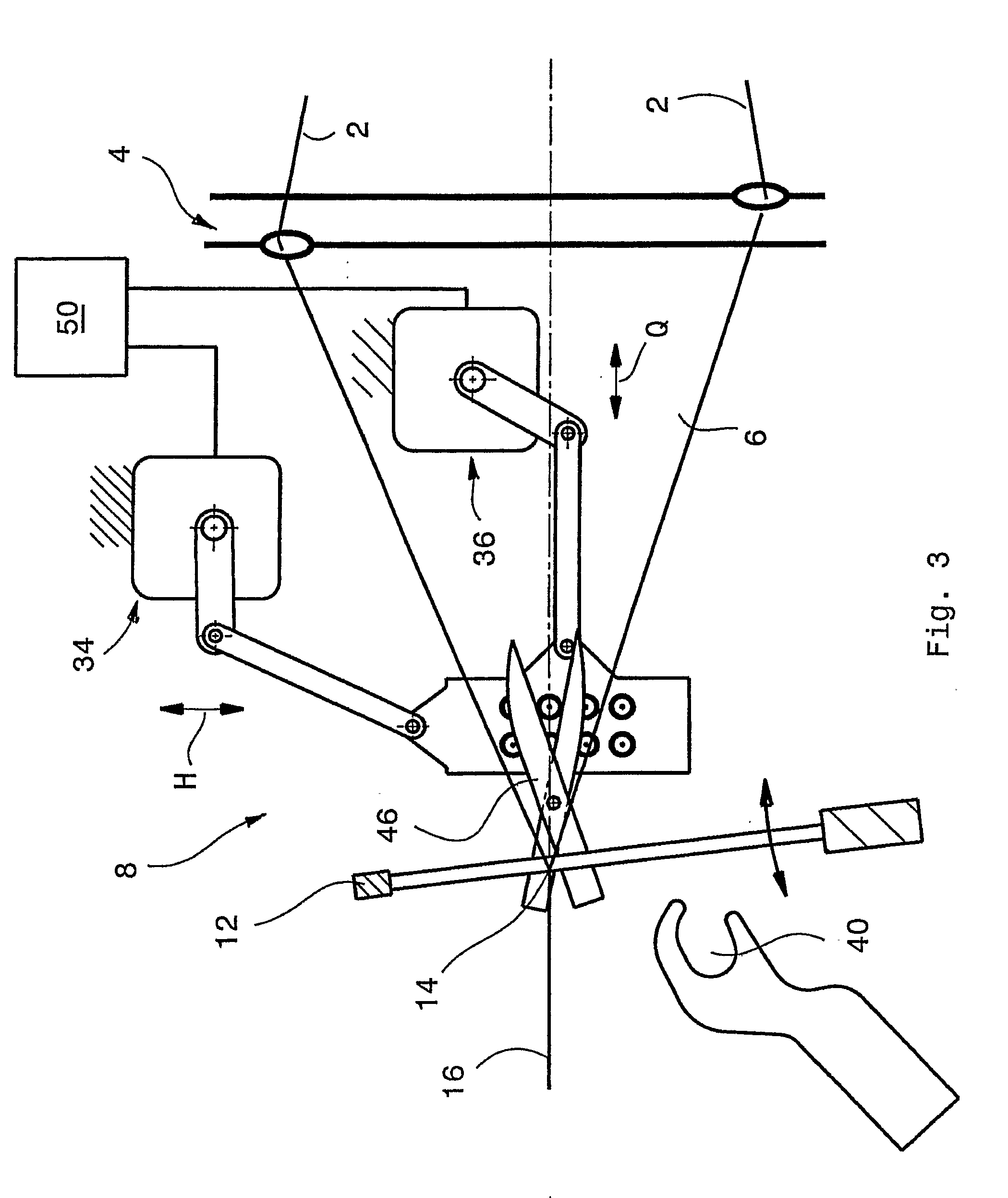

[0019]FIGS. 1 to 4 show the weft insertion region of a weaving machine in a diagrammatic illustration, only the parts important for the present invention being shown. All the other features of the weaving machine are state of the art.

[0020]FIGS. 1 and 3 show the weaving region of a weaving machine, at which warp threads 2 are moved by means of a shedding device 4, for example a Jacquard device, to an open shed 6, into which a weft thread 10 is inserted by means of a weft insertion device 8. By means of a reed 12, the weft thread 10 is beaten up at a beating-up edge 14, so that a cloth web 16 is obtained.

[0021]The weft insertion device 8 is designed pneumatically and has a nozzle block 20 which, in the present example, has eight blow nozzles 22 which, according to FIG. 4, are arranged in pairs in transverse direction Q, according to FIG. 2 four pairs of such blow nozzles being arranged one above the other in the vertical direction H. The nozzle block 22 is arranged pivotably via a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com