Boat engine cooling system

a cooling system and engine technology, applied in the direction of motor-driven power plants, marine propulsion, vessel construction, etc., can solve the problems of clogging engines, broken blocks, fixed or replaced, and 100% effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

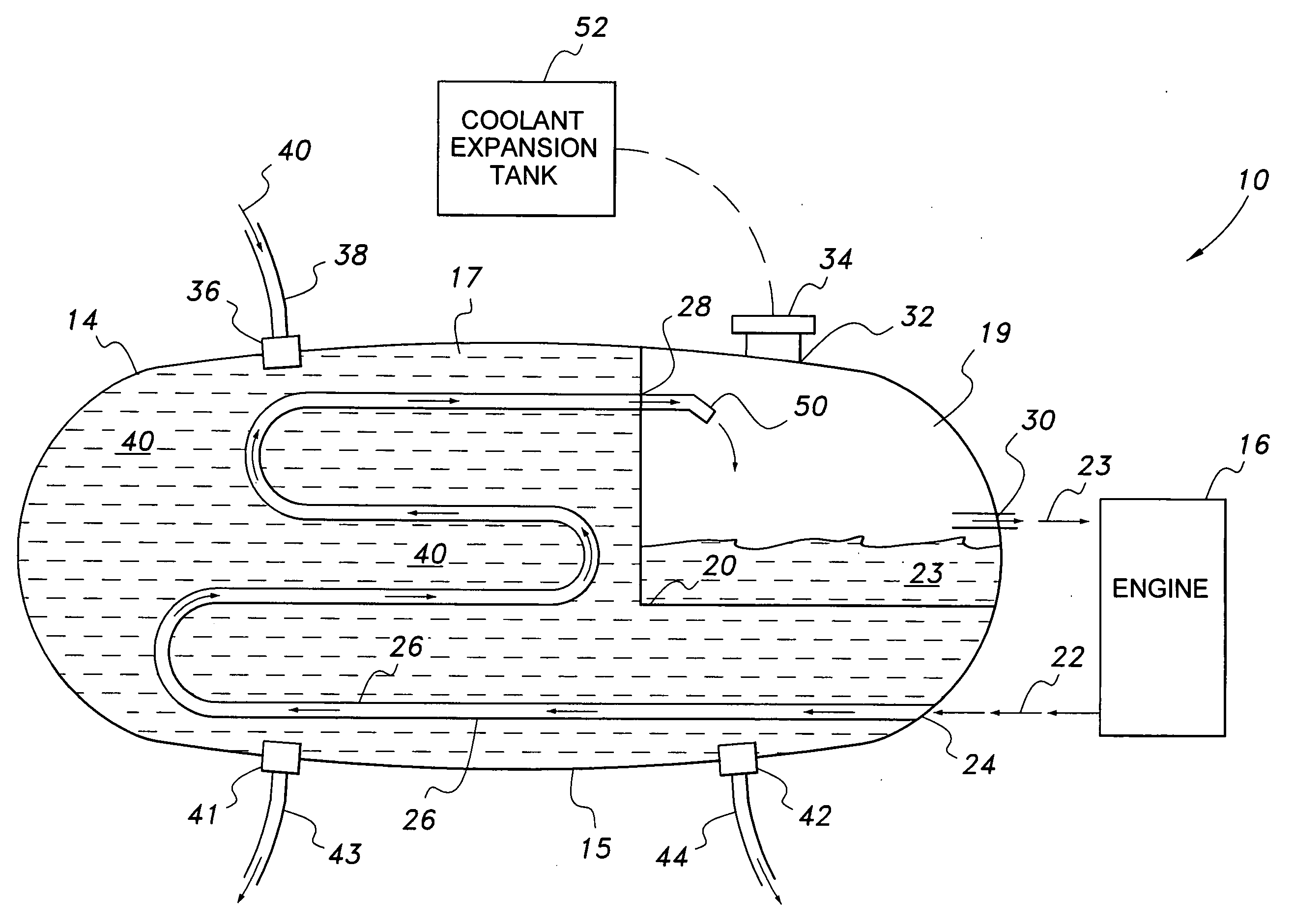

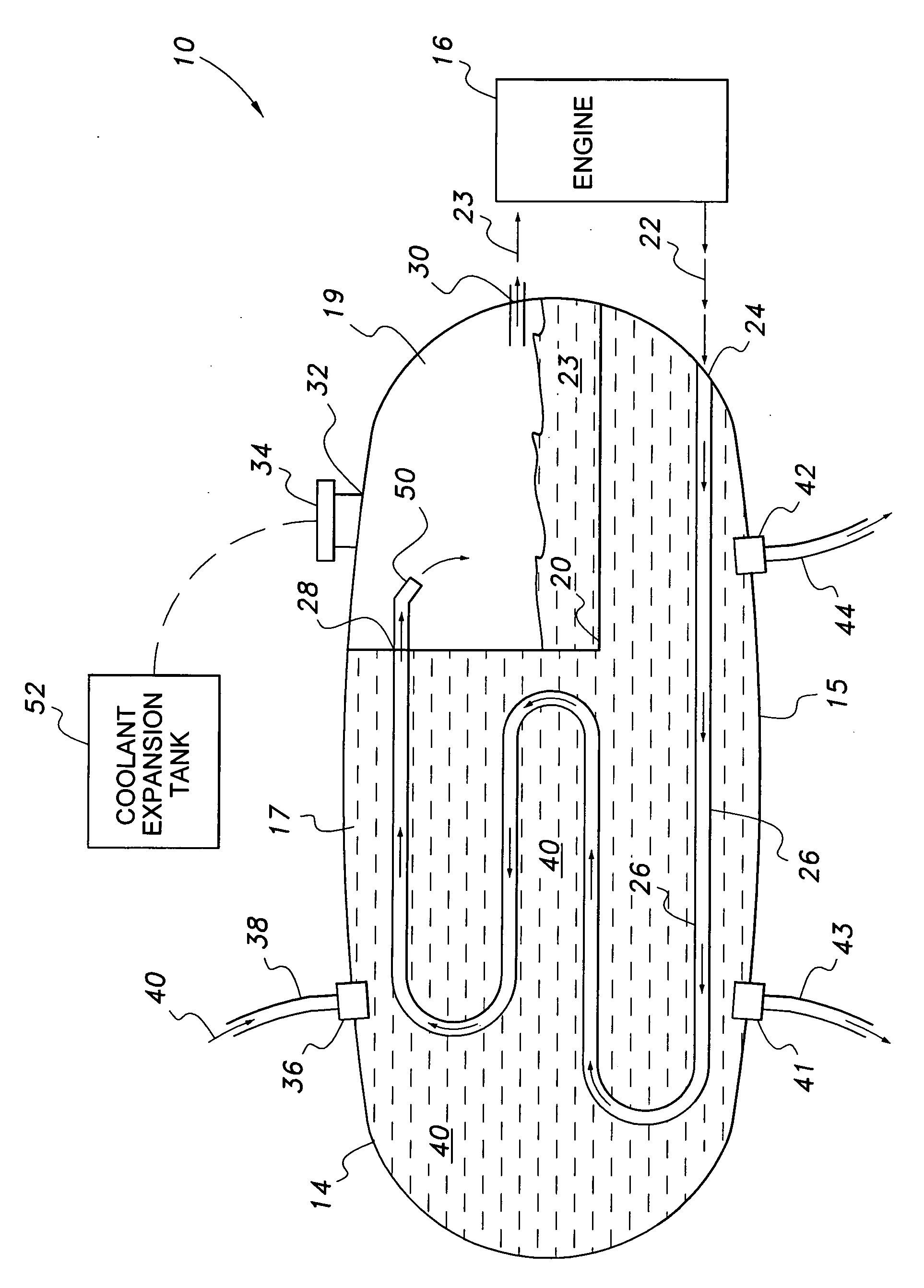

[0014]The boat engine cooling system 10 provides cooling of the engine 16 of a boat or other nautical craft through injection of both chemical engine coolant, such as antifreeze, and environmental water; i.e., the water the boat is passing through. The boat engine cooling system is preferably applied to an inboard engine 16. It should be understood that the system 10 and engine 16 shown in the sole drawing FIGURE may be used with any type of marine propulsion system, whether an inboard or outboard engine.

[0015]The boat engine cooling system 10 includes a hollow tank 14. As shown in the drawing, the hollow tank 14 defines a reservoir. Hollow tank 14 is mounted within or on the boat and is connected to the boat engine 16, as will be described below in greater detail. An engine coolant inlet port 24, an engine coolant outlet port 30, a water inlet port 36 and a pair of water outlet ports 41, 42 are all formed through an outer wall 15 of the hollow tank 14. A pressure relief port 32 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com