Light emitting device and method for producing same

a light emitting device and light source technology, which is applied in the direction of discharge tube luminescent screen, discharge tube/lamp details, luminescent compositions, etc., can solve the problems of difficult control of the amount of resin to be applied, difficult control of the color temperature of the light emitting device, and color irregularities, etc., to reduce color irregularities, high emission power, and color reproducibility good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

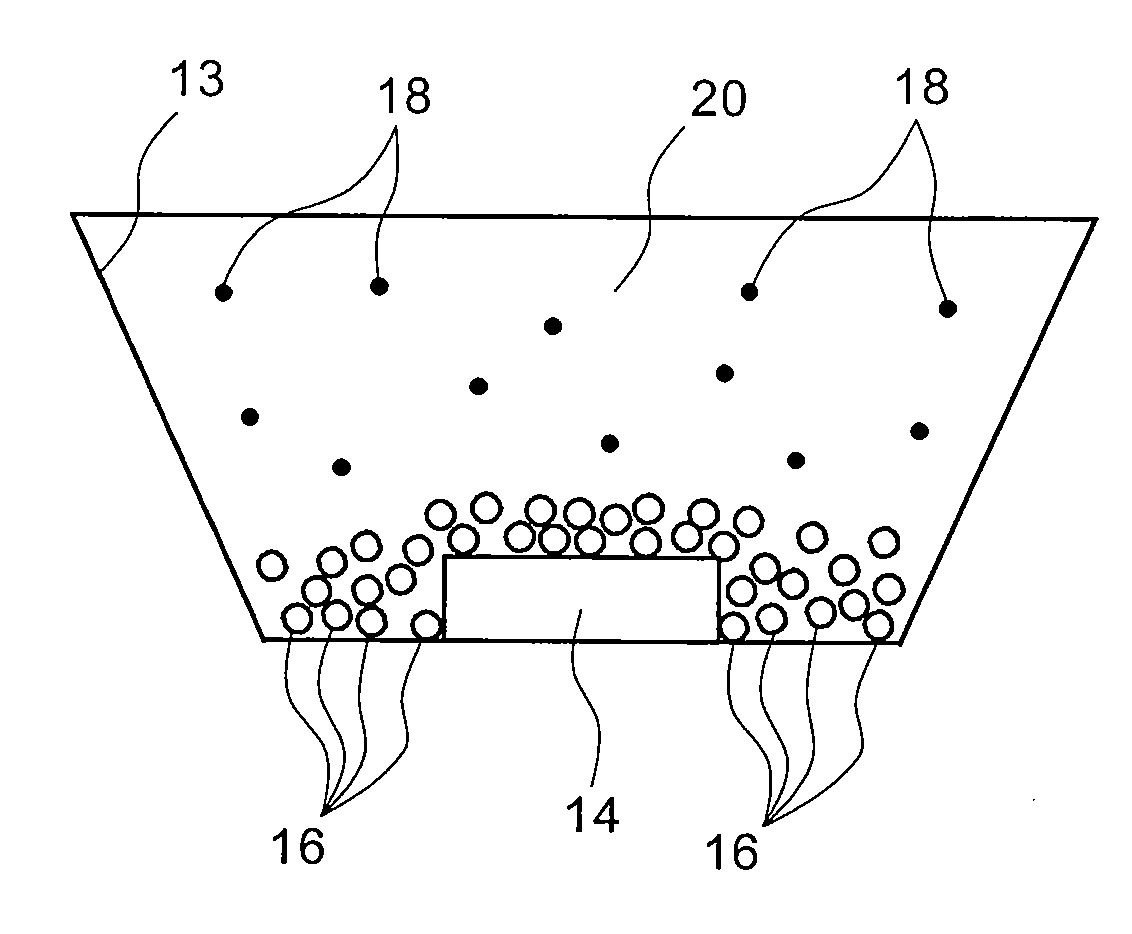

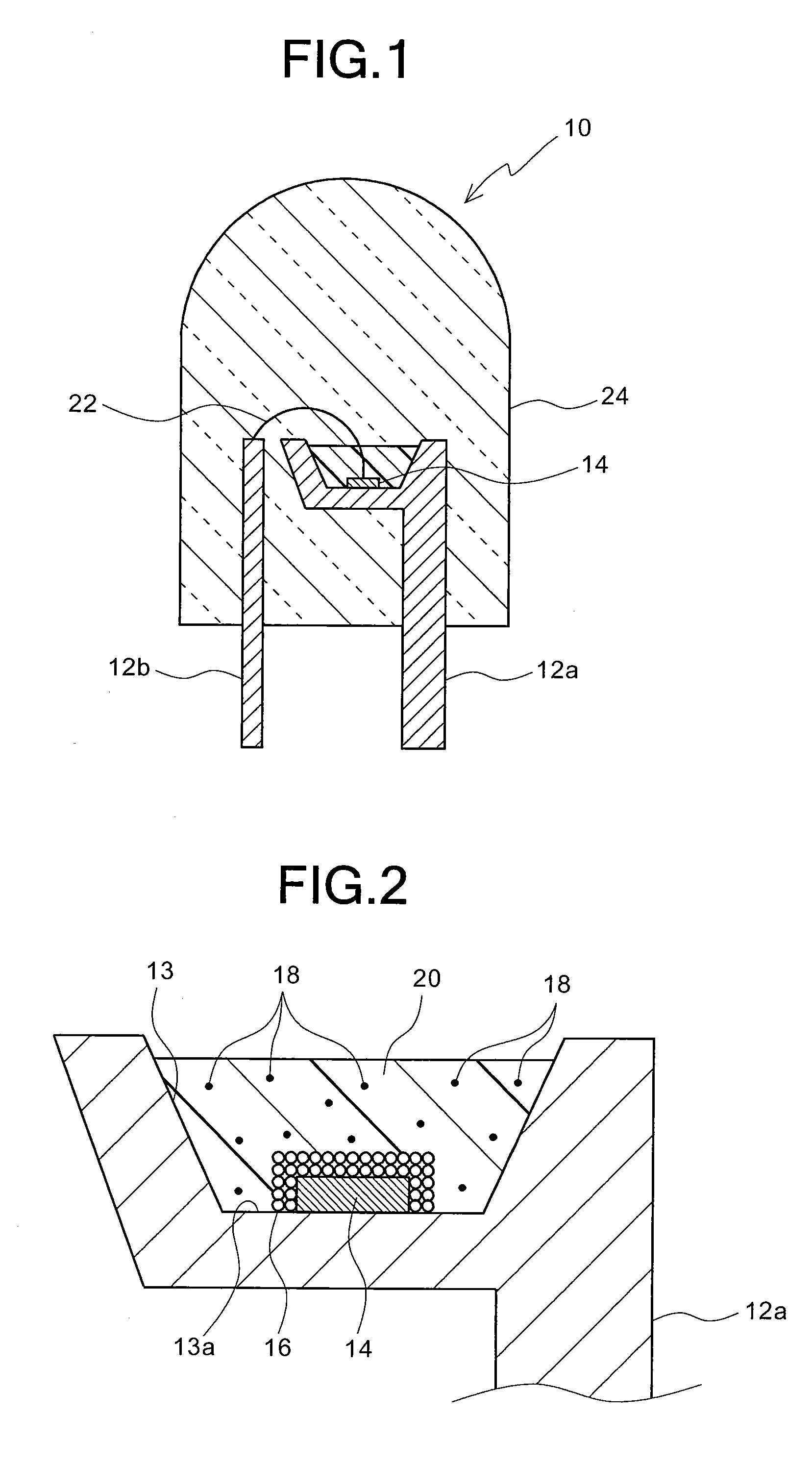

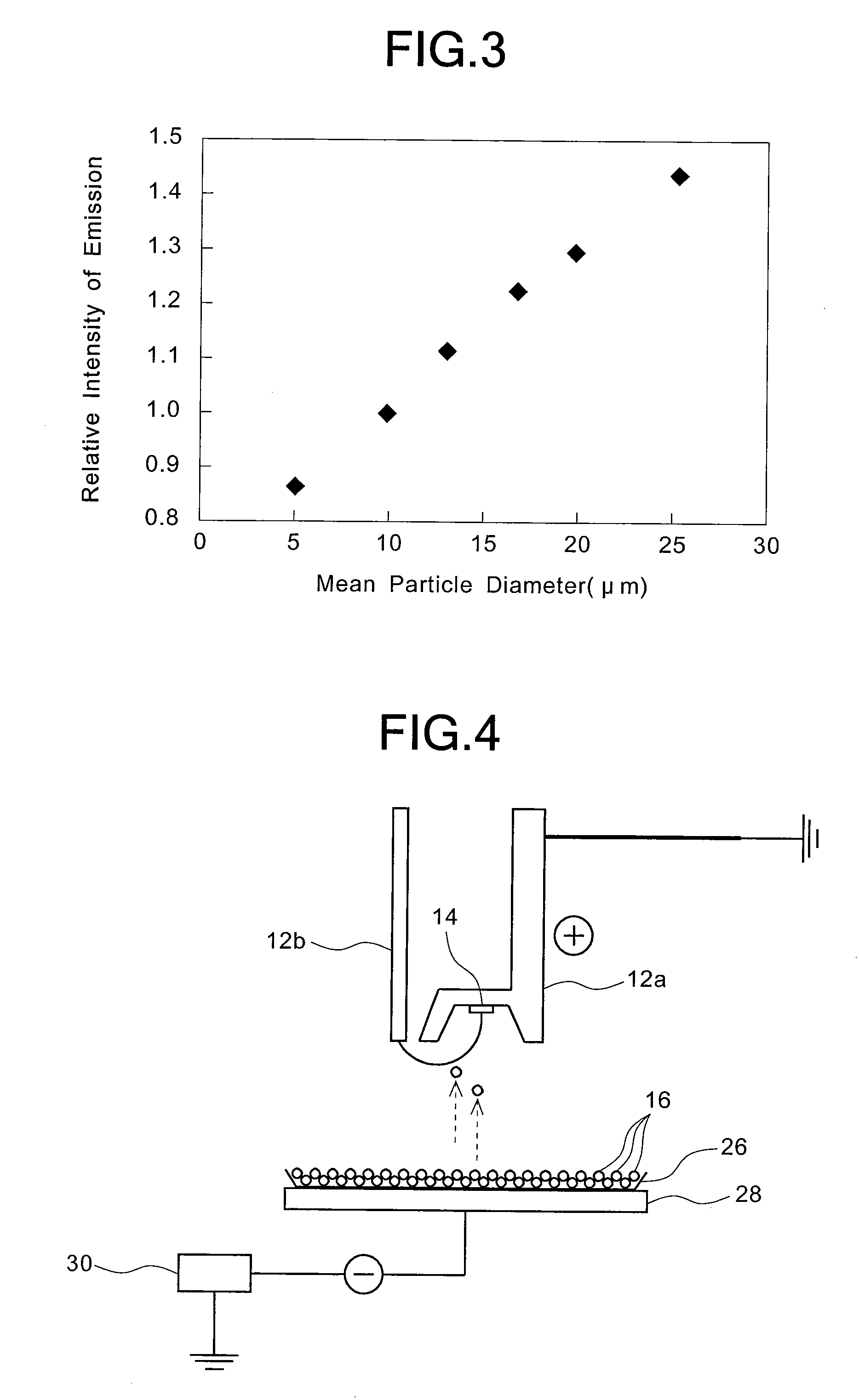

[0048]FIG. 1 is a sectional view schematically showing the first preferred embodiment of a light emitting device according to the present invention, and FIG. 2 is an enlarged sectional view of a cup portion of one of a pair of lead frames, on which a light emitting element of the light emitting device of FIG. 1 is mounted. As shown in FIGS. 1 and 2, the light emitting device 10 in this preferred embodiment comprises: a pair of lead frames 12a and 12b arranged at an interval; a light emitting element 14 which is mounted on the bottom face 13a of a cup (recessed portion) 13 formed in the tip end portion of one lead frame 12a; large phosphor particles 16 which are arranged so as to cover the surface of the light emitting element 14; a sealing member 20 containing small phosphor particles 18, which is filled in the cup 13 of the lead frame 12a so as to cover the large phosphor particles 16; and a transparent mold member 24 which covers the tip end portions of the lead frames 12a and 12b...

second preferred embodiment

[0061]Since a light emitting device and a method for producing the same in the second preferred embodiment are substantially the same as those in the first preferred embodiment, except for the preferred materials of the large phosphor particles 16 and small phosphor particles 18, the duplicate descriptions thereof are omitted.

[0062]Although the large phosphor particles 16 and the small phosphor particles 18 may be made of the same material or different materials, they may be made of such materials that light observed from the outside becomes white light if they are combined with the light emitting element 14.

[0063]Furthermore, if a resin material is used as the material of the sealing member 20, it is difficult for the phosphor particles to be precipitated, so that it is possible to prevent irregular color due to the precipitation of the phosphor particles in the resin, since the phosphor particles to be dispersed in the resin are the small phosphor particles 18.

[0064]Examples of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com