Modified ethylene-vinyl alcohol copolymer, gas barrier resin, and molded article of the same

a technology of ethylenevinyl alcohol and ethylenevinyl alcohol, which is applied in the direction of synthetic resin layered products, pipes, tyre parts, etc., can solve the problems of interior bending fatigue resistance, heat resistance and bending fatigue resistance, and achieve superior gas barrier properties, and heat resistance and bending fatigue resistance. the effect of superiority

Inactive Publication Date: 2010-02-25

YOKOHAMA RUBBER CO LTD

View PDF13 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0016]The modified ethylene-vinyl alcohol copolymer of the present invention is superior in gas barrier property, heat resistance, and bending fatigue resistance. Because the modified ethylene-vinyl alcohol copolymer of the present inve

Problems solved by technology

Ethylene-vinyl alcohol copolymers have superior gas barrier property, b

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 7

[0053]80 parts by weight of anhydrous maleate-modified EPM (Tafmer® MP-0620 made by Mitsui Chemicals, Inc.) were added to 100 parts by weight of the modified ethylene-vinyl alcohol copolymer of Example 3 and melt kneaded to prepare a gas barrier resin. Upon evaluation, the resin had a bending fatigue number of 52000, melting temperature of 160° C., and air permeability coefficient of 32.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Login to view more

Abstract

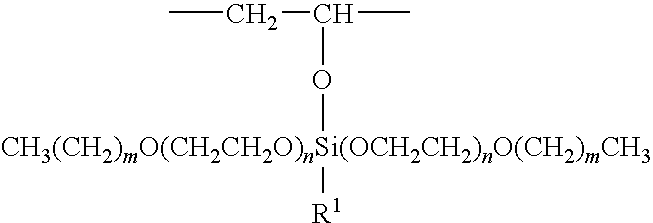

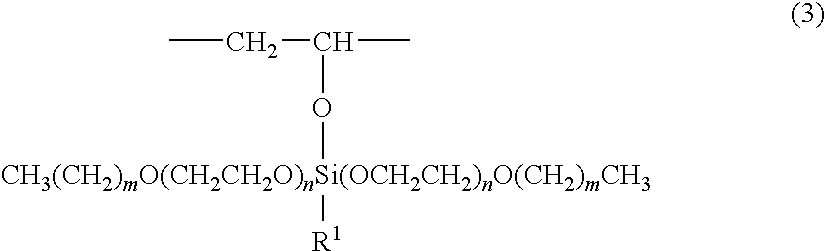

Ethylene-vinyl alcohol copolymers have superior gas barrier properties, but are inferior in bending fatigue resistance. The present invention improves bending fatigue resistance without reducing the gas barrier property and heat resistance. An ethylene-vinyl alcohol copolymer having an ethylene content of 20 to 50 percent by mole is modified by incorporating 0.01 to 1% mol of a structural unit expressed by the following formula (3):

wherein, n indicates an integer of 2 to 5, m indicates an integer of 10 to 20, and R1 indicates a C1 to C20 aliphatic hydrocarbon group provided that R1 may contain a mercapto group, thioester group, sulfenamide, vinyl group, methacryloxy group, or acryloxy group. The modified ethylene vinyl alcohol copolymer may be used as a gas barrier resin and this gas barrier resin may be shaped or laminated and used in various applications such as in pneumatic tires and hoses.

Description

TECHNICAL FIELD[0001]The present invention relates to a modified ethylene-vinyl alcohol copolymer, more particularly relates to a gas barrier resin comprising the modified ethylene-vinyl alcohol copolymer and a molded article prepared from the same, particularly a pneumatic tire and a hose.BACKGROUND ART[0002]Ethylene-vinyl alcohol copolymers have superior gas barrier property, but have the defect that they are interior in bending fatigue resistance. To improve on this, there is known a method of modifying an ethylene-vinyl alcohol copolymer with an epoxy compound. See Japanese Unexamined Patent Publication No. 2003-231715.SUMMARY OF INVENTION[0003]Technical Problem[0004]However, if modifying an ethylene-vinyl alcohol copolymer with an epoxy compound, the bending fatigue resistance will be improved, but the gas barrier property and heat resistance (melting point) will tend to drop. The present invention addresses the matter of improving the drawback of an ethylene-vinyl alcohol copo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B32B27/08C08F210/02

CPCB32B27/08B32B27/30B60C1/0008C08F8/42B60C2005/145F16L2011/047F16L11/08C08F8/02C08F216/06B32B27/18B32B27/20B32B27/26B32B27/285B32B27/302B32B27/304B32B27/306B32B27/308B32B27/32B32B27/34B32B27/365B32B27/40B32B1/00B32B1/08B32B2250/24B32B2270/00B32B2307/306B32B2307/50B32B2307/7242B32B2597/00B32B2605/00Y10T428/31573Y10T428/31913Y10T428/31855C08F210/02C08F230/08C08J5/00

Inventor MOROOKA, NAOYUKI

Owner YOKOHAMA RUBBER CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap