Fastening member and external wall construction structure

a technology of fastening member and external wall, which is applied in the direction of walls, constructions, covering/linings, etc., can solve the problems of limited precision with which the exterior wall boards are put up, difficulty in avoiding the presence of gaps between the exterior wall boards and the elastic material in such an external wall construction structure, and impaired elasticity, etc., to achieve reliable locking and fixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

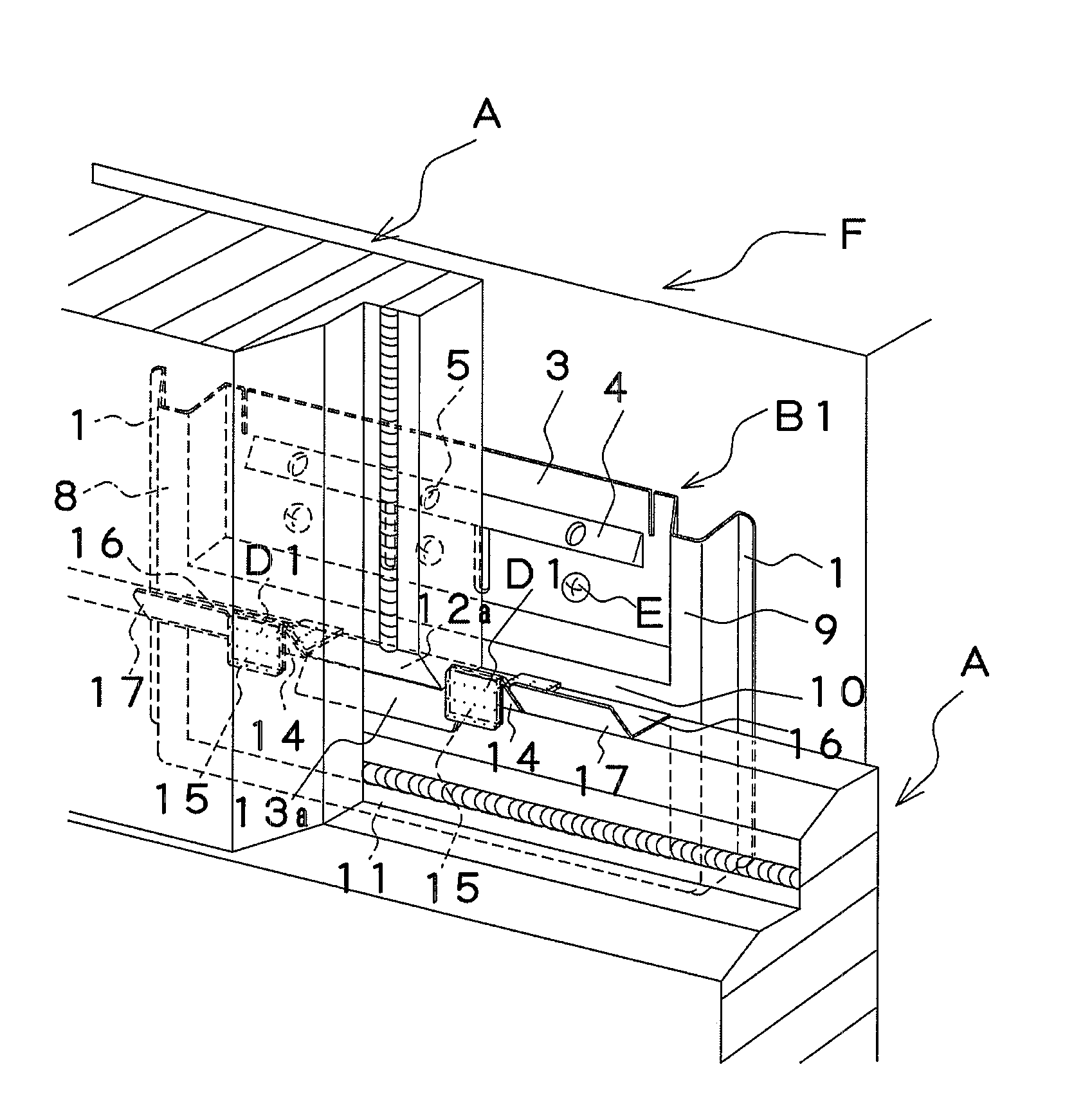

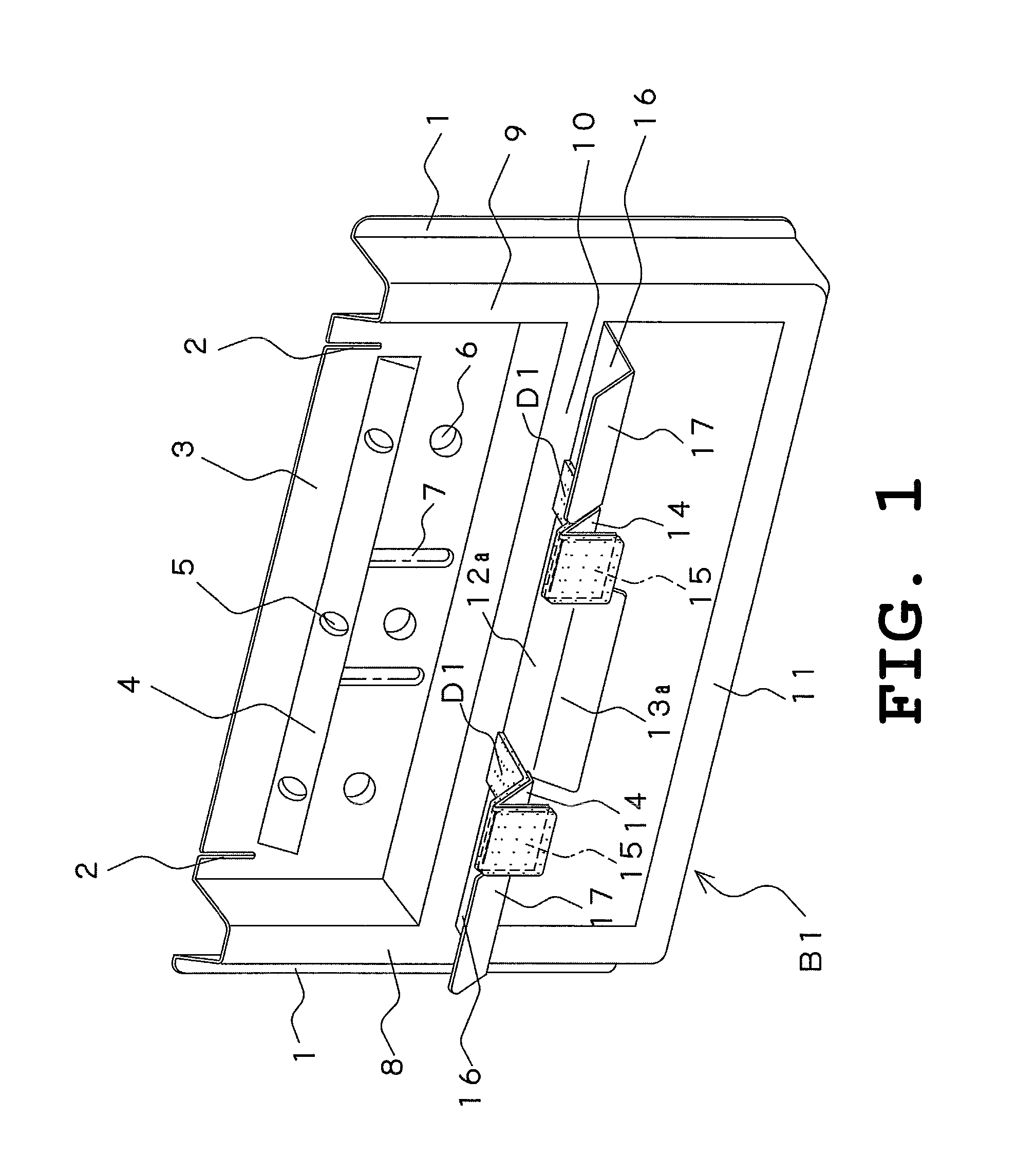

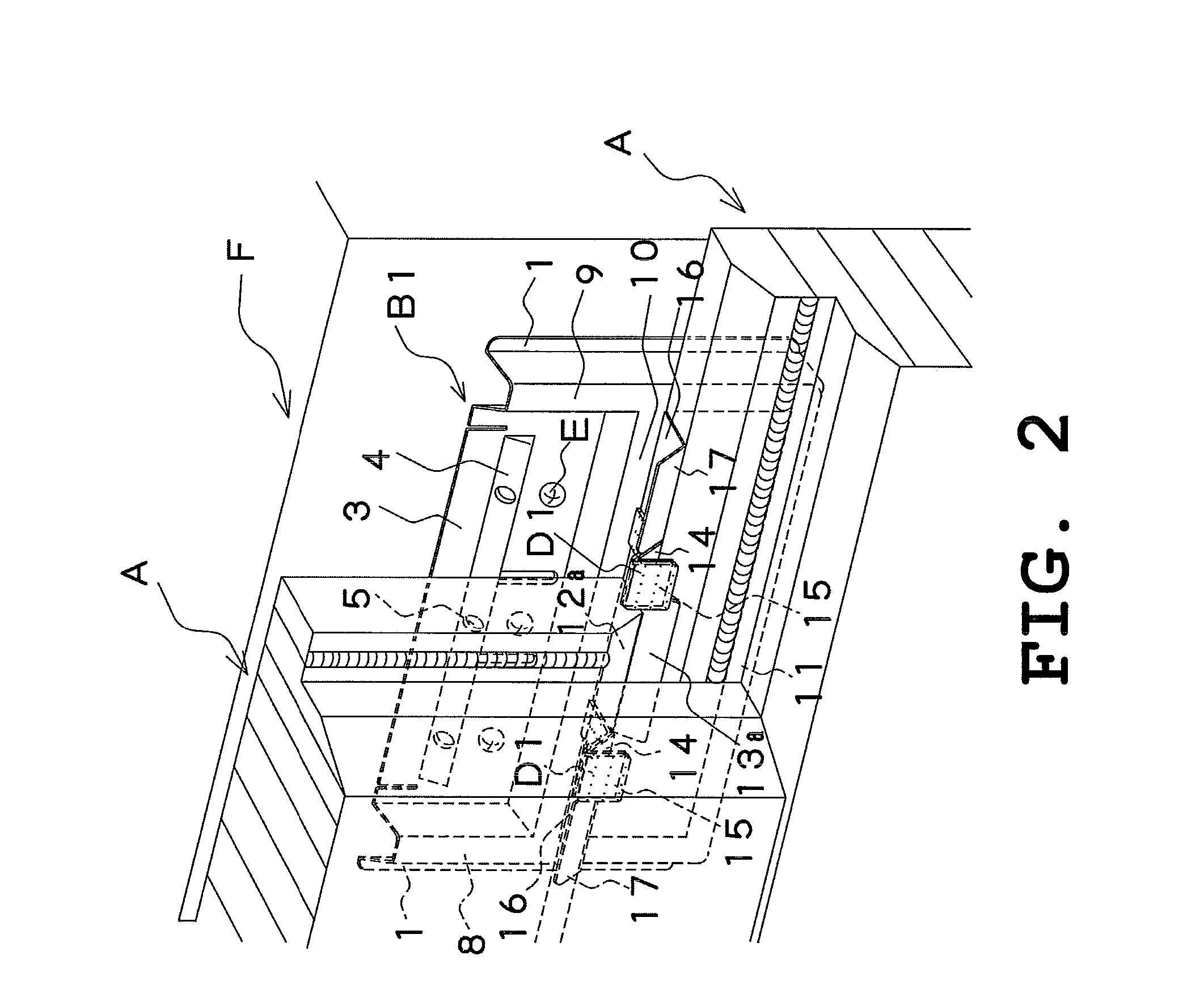

[0049]FIG. 1 is a diagram illustrating an embodiment of a fastening member according to the present invention.

[0050]A fastening member B1 illustrated in FIG. 1 is manufactured out of a Galvalume steel sheet having a thickness of 0.8 mm. At the left and right sides, the fastening member B1 comprises a left support portion 8 and a right support portion 9 that abut each the back surface of an exterior wall board when the board is fastened.

[0051]In the area flanked by the left support portion 8 and the right support portion 9, the fastening member B1 comprises a base plate portion 3 that constitutes a mount portion to be fixed to a building frame; a central support portion 10 that abuts the back surface of an exterior wall board when the board is fastened; a central horizontal raised portion 12a that is erected in a horizontal direction, frontward from the lower end of the central support portion 10; a downwardly bent portion 13a bent downwards from the front end of the central horizont...

embodiment 2

[0073]FIG. 4 is a diagram illustrating another embodiment of a fastening member according to the present embodiment.

[0074]The fastening member B2 illustrated in FIG. 4 is identical to the fastening member B1 illustrated in FIG. 1 except that herein a waterproof material D2 comprises bentonite and EPDM, and has elasticity. Specifically, the fastening member B2 is also formed out of a Galvalume steel sheet, and comprises flange portions 1, cutouts 2, a base plate portion 3, a bulging portion 4, nail openings 5, screw holes 6, ribs 7, a left support portion 8, aright support portion 9, a central support portion 10, a lower support portion 11, a central horizontal raised portion 12a, a downwardly bent portion 13a, upwardly bent portions 14, front plate portions 15, bearing portions 16 and upper-board locking portions 17. The waterproof material D2 is provided on the left and right ends of the central horizontal raised portion 12a, the top surfaces of the upwardly bent portions 14 and th...

embodiment 3

[0084]FIG. 7 is a diagram illustrating yet another embodiment of a fastening member according to the present embodiment.

[0085]The fastening member B3 illustrated in FIG. 7 is identical to the fastening member B1 illustrated in FIG. 1, except that herein a downwardly bent portion 13b has a black tape adhered thereto. Specifically, the fastening member B3 is also formed out of a Galvalume steel sheet, and comprises flange portions 1, cutouts 2, a base plate portion 3, a bulging portion 4, nail openings 5, screw holes 6, ribs 7, a left support portion 8, a right support portion 9, a central support portion 10, a lower support portion 11, a central horizontal raised portion 12a, upwardly bent portions 14, front plate portions 15, bearing portions 16 and upper-board locking portions 17. A waterproof material D1 is provided on the left and right ends of the central horizontal raised portion 12a, the top surfaces of the upwardly bent portions 14 and the front surfaces of the front plate po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com