Advanced Capillary Force Vaporizers

a technology of capillary force and vaporizer, which is applied in the direction of steam generation using steam absorption, lighting and heating apparatus, heating types, etc. it can solve the problems of insufficient robustness of devices, inconvenient use of pressurized liquid sources, and prone to leakage, so as to improve the reliability and the effect of improving the respons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

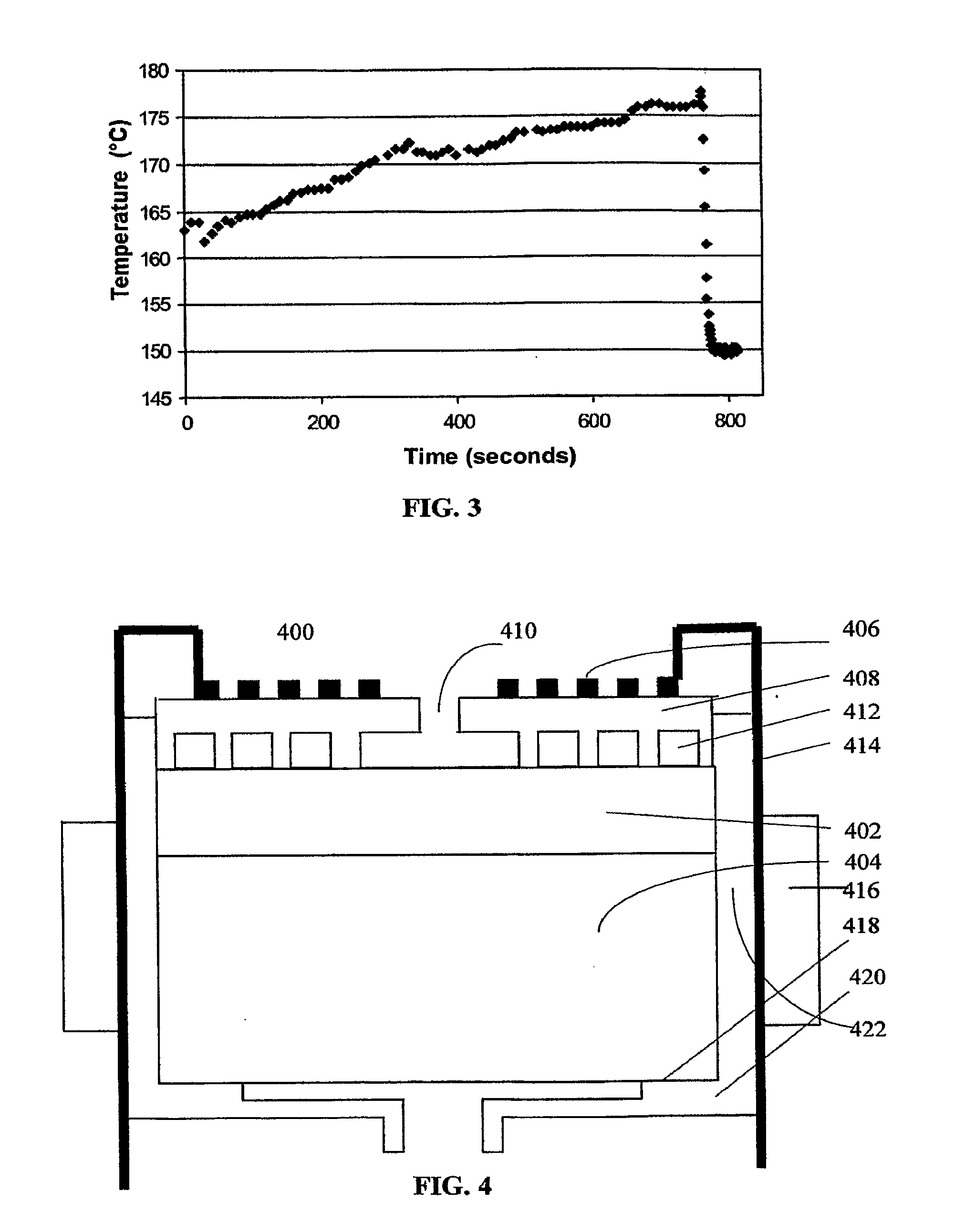

[0014]In early applications that involved the use of capillary devices, a liquid was fed into or positioned within the device at or near atmospheric pressure. The liquid feed was generally a fuel or combustible material, and the purpose for the capillary pump or capillary vaporization module was the generation of flames for cooking or for providing light. Accordingly, the devices were typically operated at temperatures that exhibited flame temperatures up to about 1090° C. (2000° F.), with the surface of the device reaching temperatures in excess of about 350° C. (660° F.). However, these prior art devices were prone to failure modes due to combustion of the very materials they attempted to vaporize and burn. Often, the devices would become clogged with the liquid fuel feed being used. Worse yet, many devices were prone to cracking due to constraints placed upon device components by the very nature of the peripheral glaze used in attempts to seal and pressurize the device.

[0015]Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap