Insect Screen Structures

a technology of insect screens and structures, applied in the field of insect screens, can solve the problem of time-consuming installation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

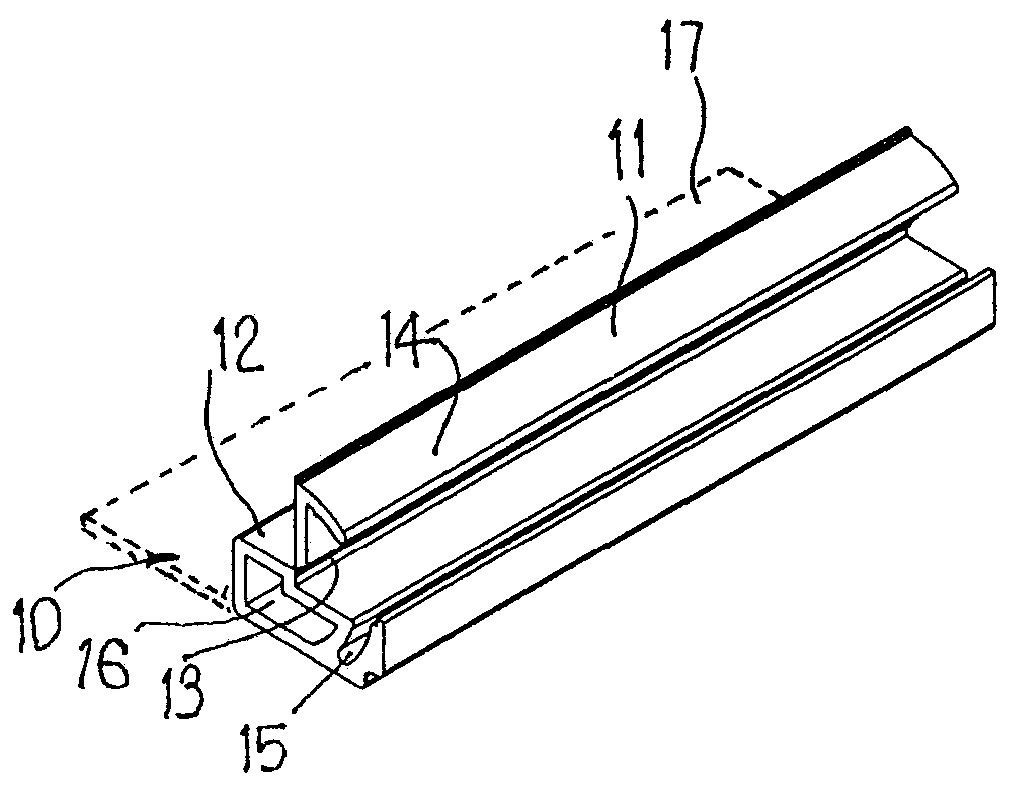

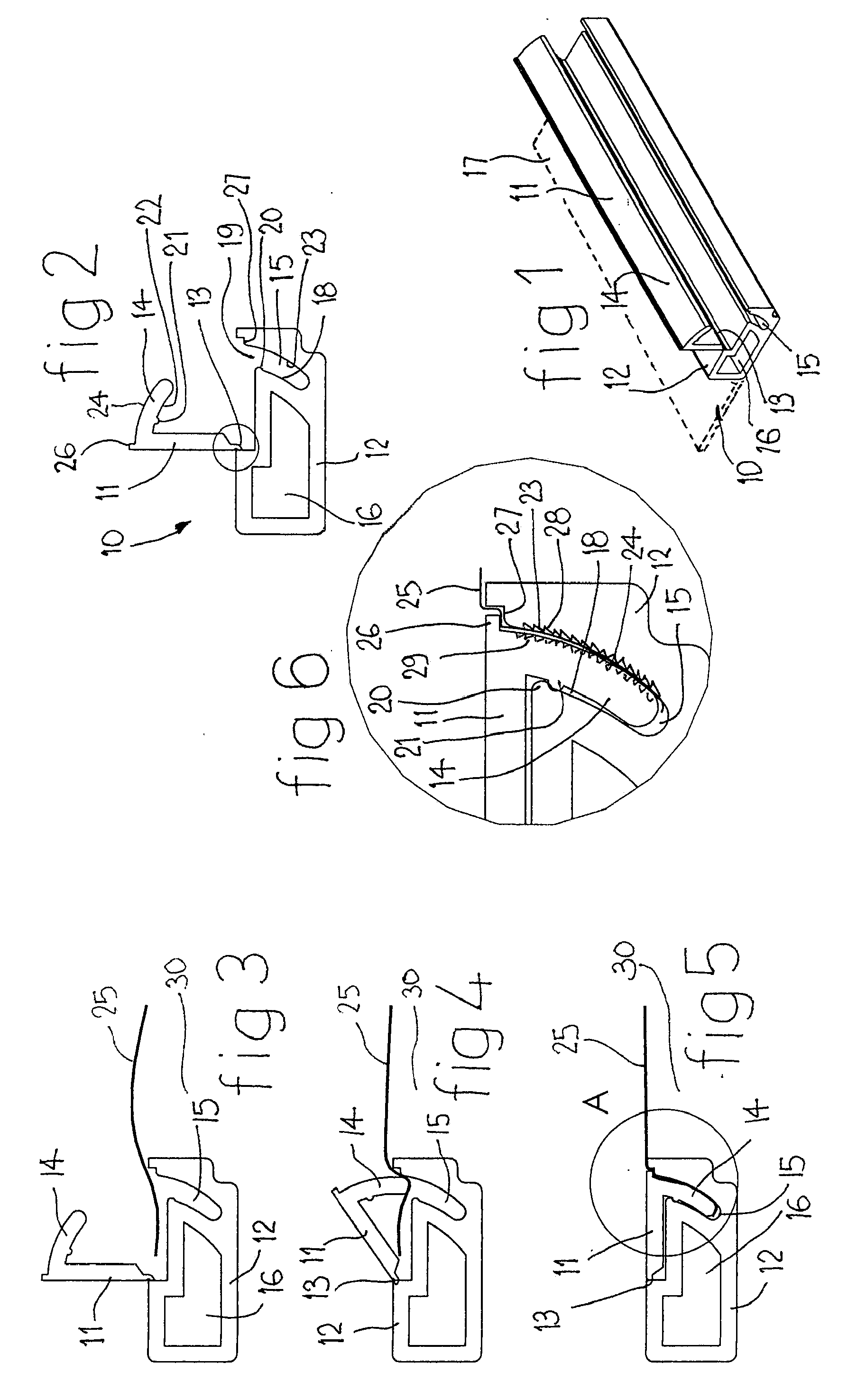

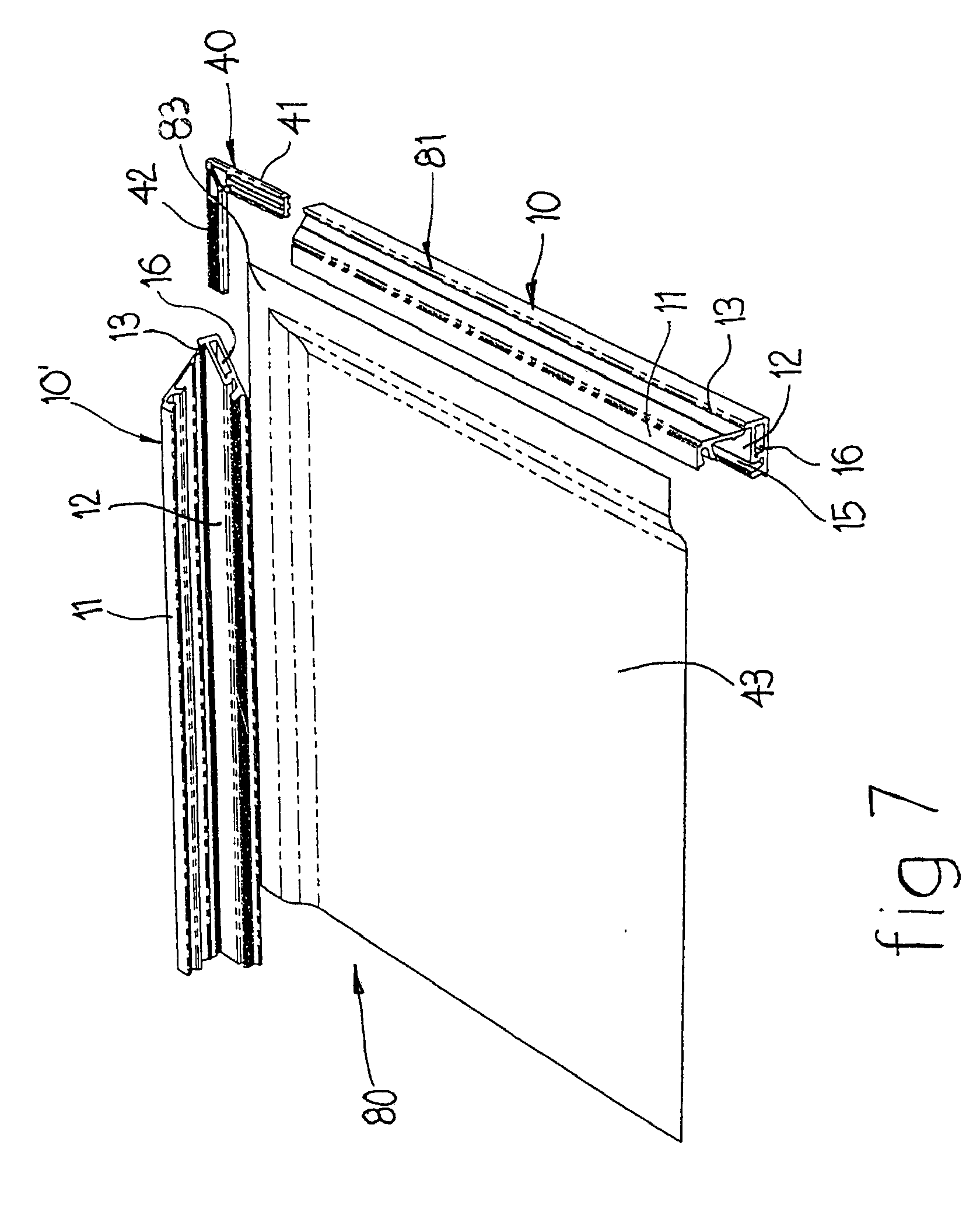

[0021]Referring to the drawings, FIG. 1 illustrates an extruded elongate section 10, which may be formed into a frame an engagement member capable of being used as is or assembled to form. The section 10 is conveniently formed in one piece with a first part 11 and a second part 12 connected by a plastics material hinge line 13. The first part 11 includes a longitudinally extending wall formation 14 that is complementary in shape to an elongate groove 15 formed in the second part 12 wherein in a first position, the wall formation 14 can be fully removed from the groove 15 (FIG. 1) or in a second position, the wall formation 14 can be fully engaged in the groove 15 (FIGS. 5, 6). Movement of the first part 11 between the aforesaid positions occurs by pivoting the first part 11 relative to the second part 12 about the hinge line 13. While a one piece construction as illustrated in the drawings is preferred, it is equally possible to make the two parts 11, 12 individually or as separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com