Vacuum storage container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

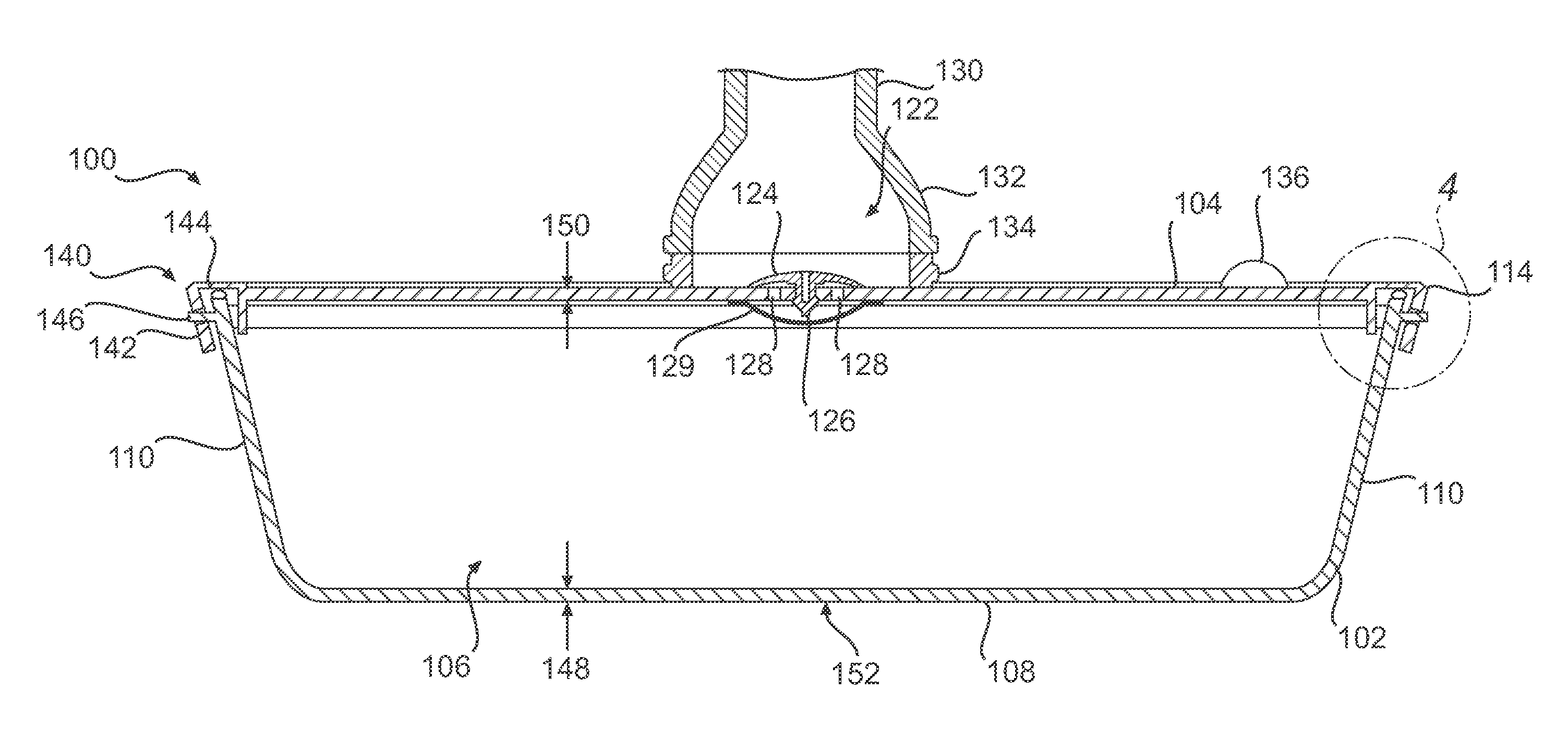

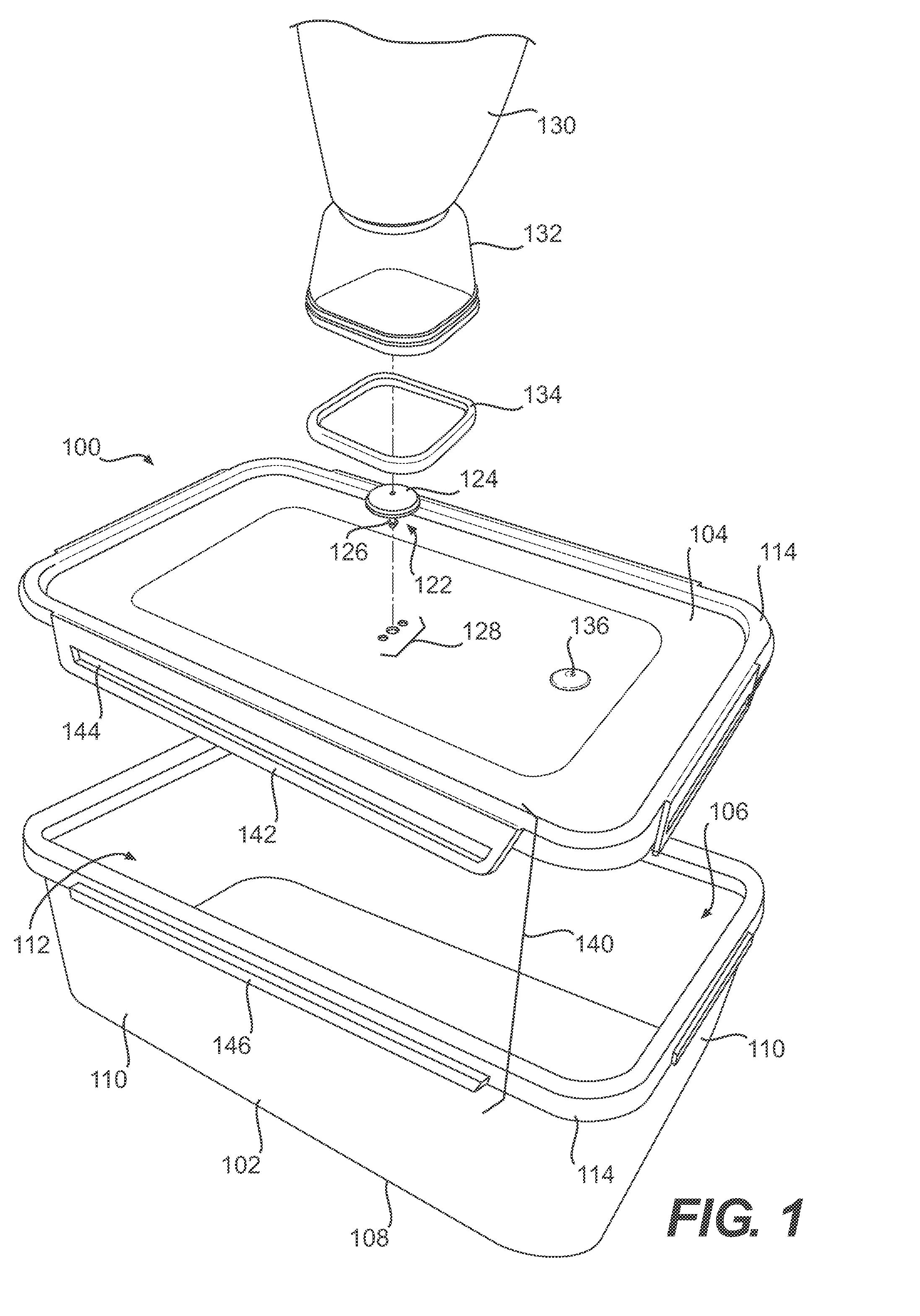

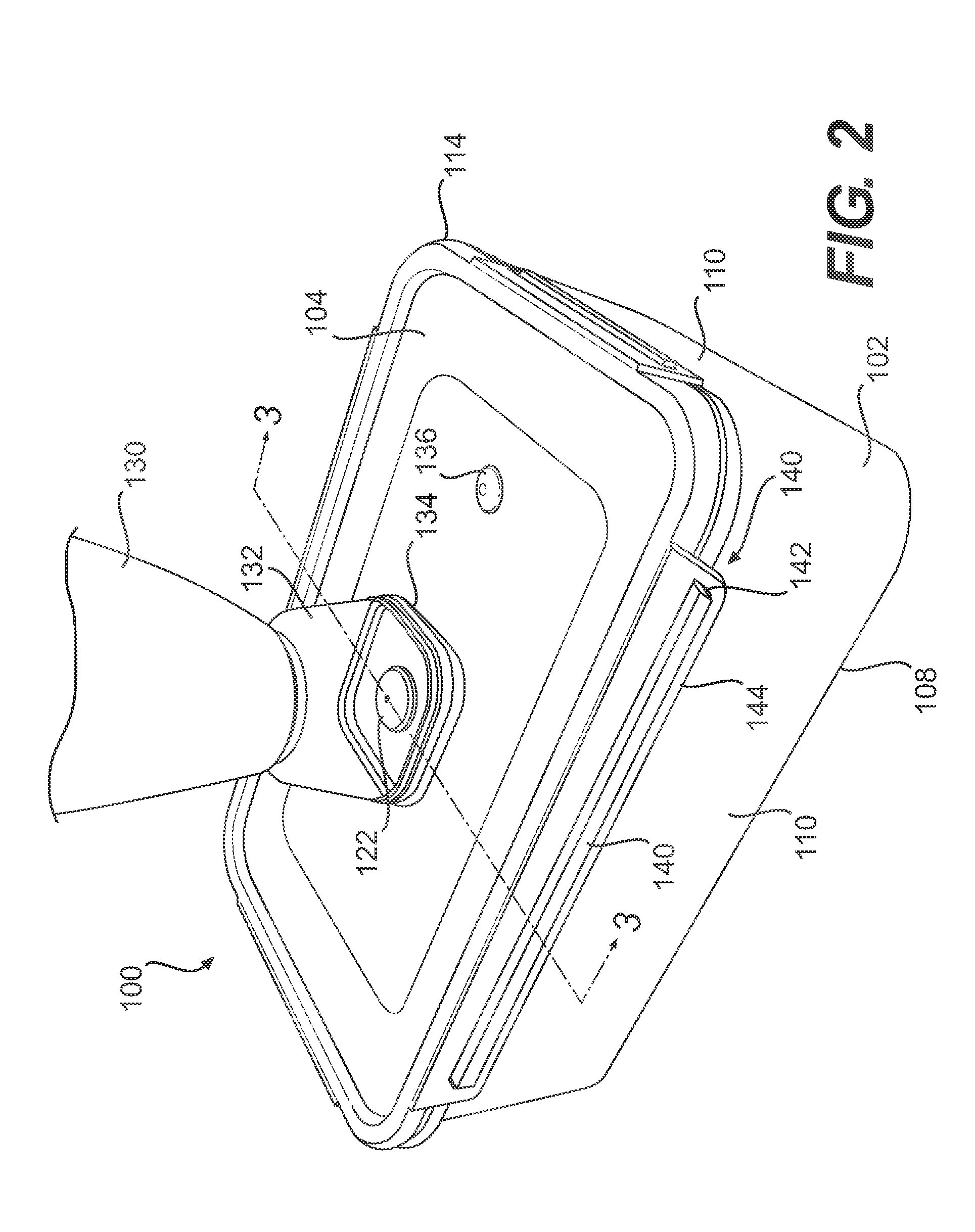

[0023]Now referring to the Figures, wherein like reference numbers refer to like elements, there is illustrated in FIGS. 1 and 2 the parts of a vacuum storage container 100 including a base 102 and a detachable lid 104 that can be connected to the base. To receive items for storage, the base 102 is shaped to provide a void or storage cavity 106. In the illustrated embodiment, the base 102 is rectangular and includes a flat, centrally located bottom panel 108 and four straight, generally upright side panels 110. In some embodiments, the upright side panels can actually angle slightly outward to facilitate nested stacking of multiple bases together. The space opposite the bottom panel 108 and surrounded by the top edges of the side panels 110 provides an opening 112 for accessing the storage cavity. The side edges of each of the side panels 110 are interconnected to bound the storage cavity 106, with the exception of the opening 112, and thereby provide the rectangular shape of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com