Heat exchangers having baffled manifolds

a technology of baffled manifolds and heat exchangers, which is applied in the direction of indirect heat exchangers, refrigeration components, lighting and heating apparatus, etc., can solve the problems of poor heat exchanger efficiency, maldistribution in the evaporator, and lack of efficiency, so as to prevent maldistribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

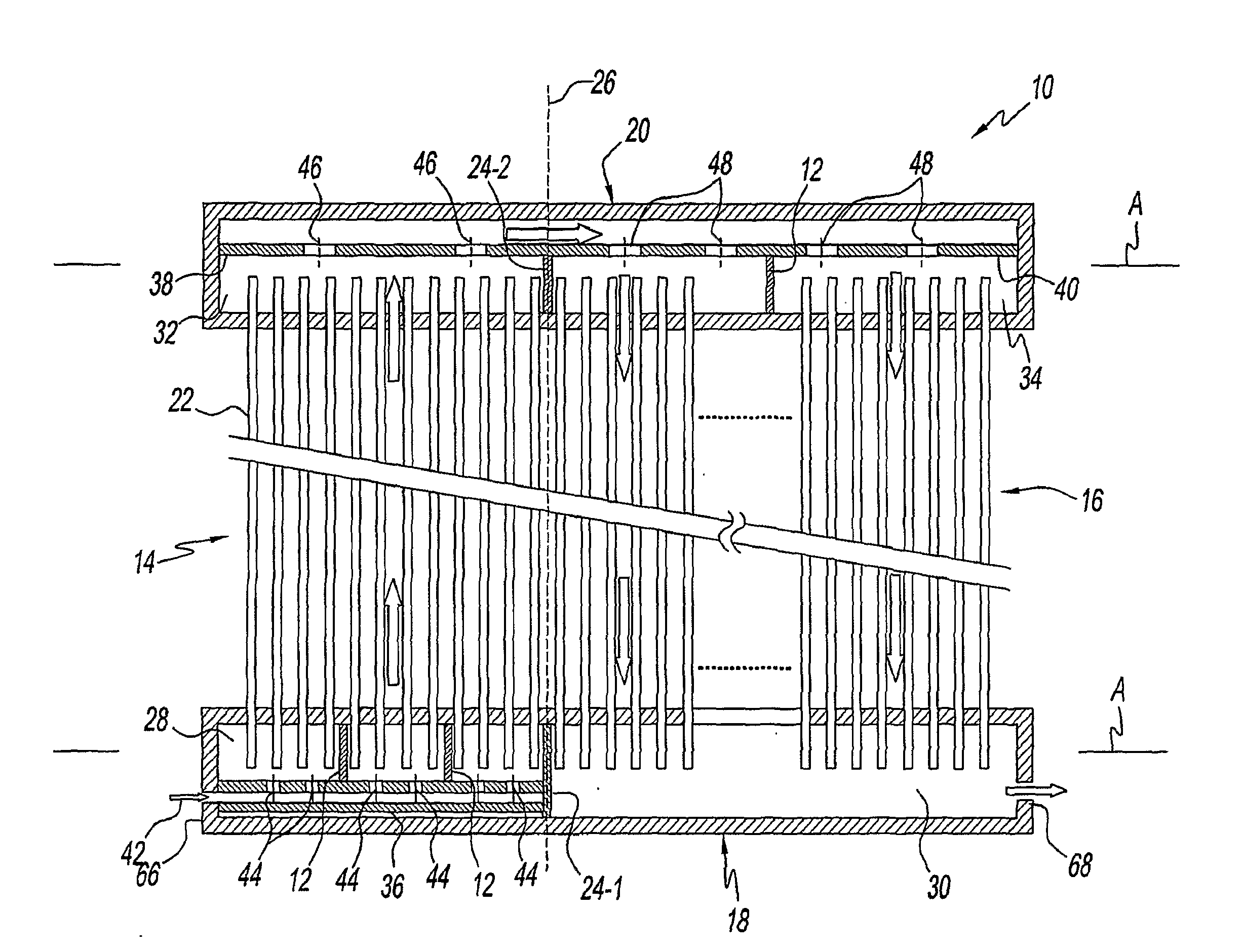

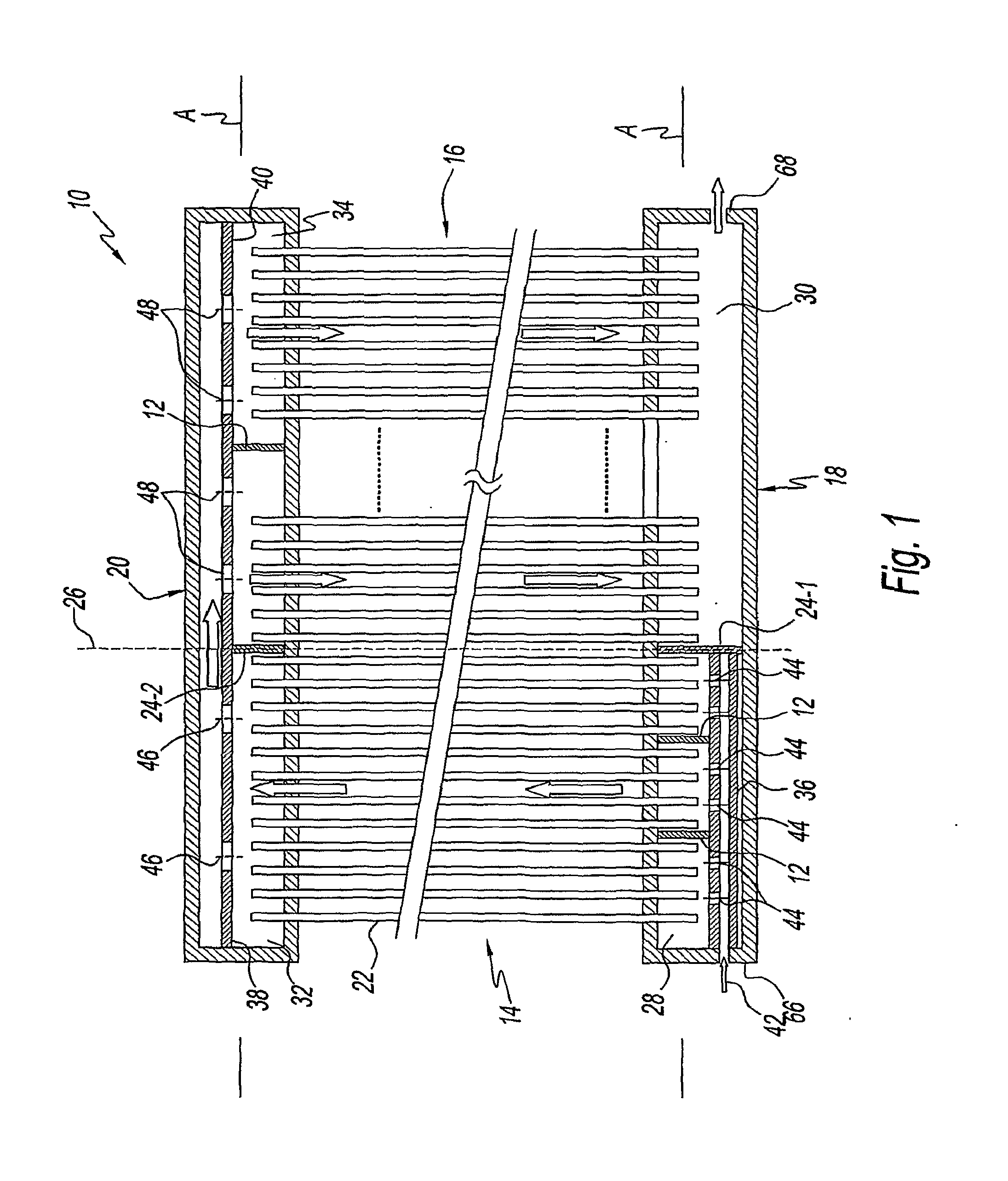

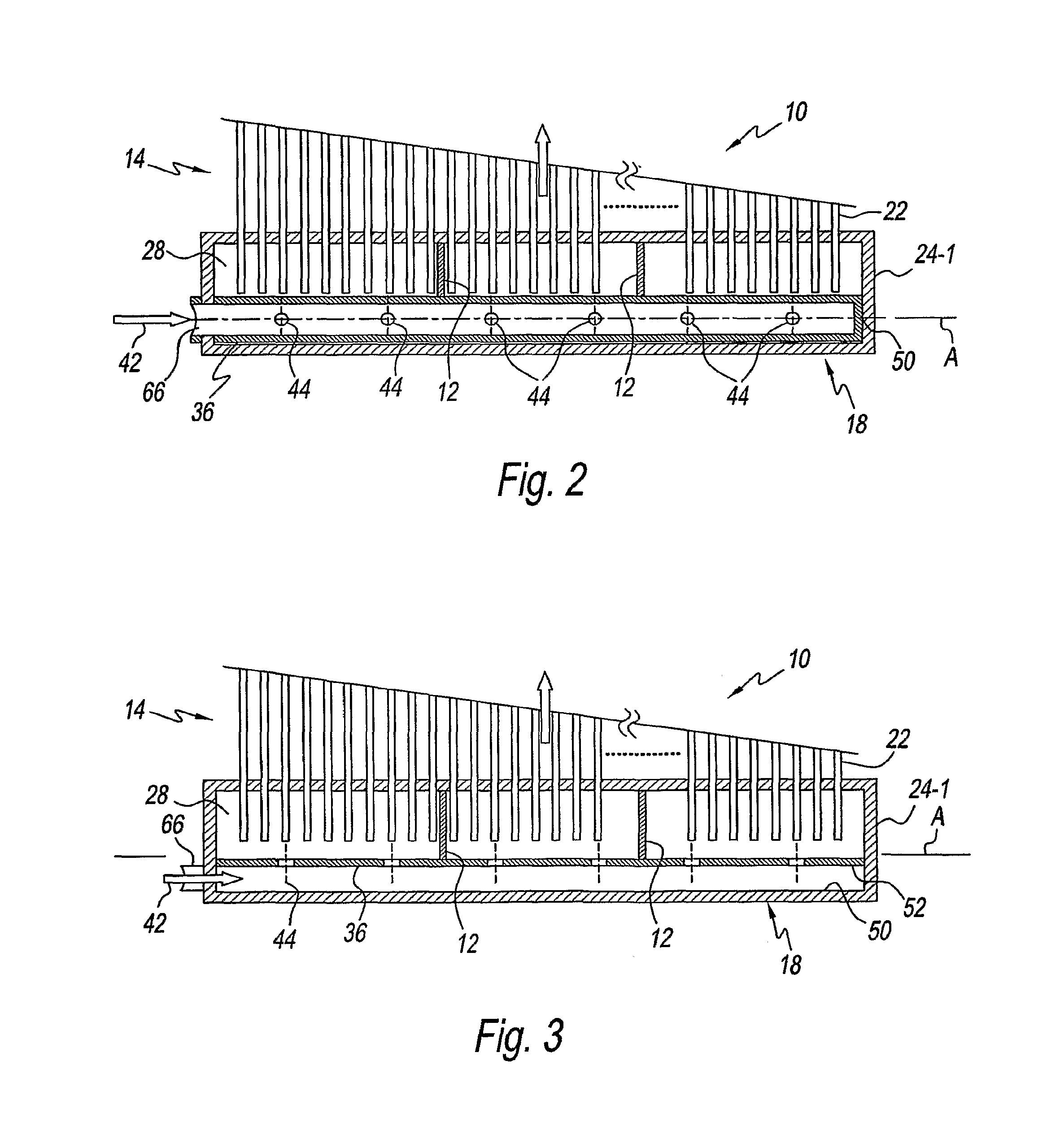

[0018]Referring now to the figures and in particular to FIG. 1, an exemplary embodiment of parallel path heat exchanger according to the present disclosure is shown and is generally referred to by reference numeral 10. Heat exchanger 10 includes one or more baffles 12 within one or more manifolds 18, 20. Advantageously, baffles 12 are configured to limit the movement of the fluid along an axis (A) of manifold 18, 20, which mitigates separation of the two-phase fluid and ensures uniform distribution within the channels of heat exchanger 10.

[0019]For purposes of clarity, FIG. 1 illustrates heat exchanger 10 as a multi-pass heat exchanger having a first pass 14 and a second pass 16. Of course, it is contemplated by the present disclosure for baffles 12 to find equal use with any parallel path heat exchanger having more or less than two passes.

[0020]Heat exchanger 10 includes a first manifold 18 and a second manifold 20 that are in fluid communication with one another by way of a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com