Package with releasable film access opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

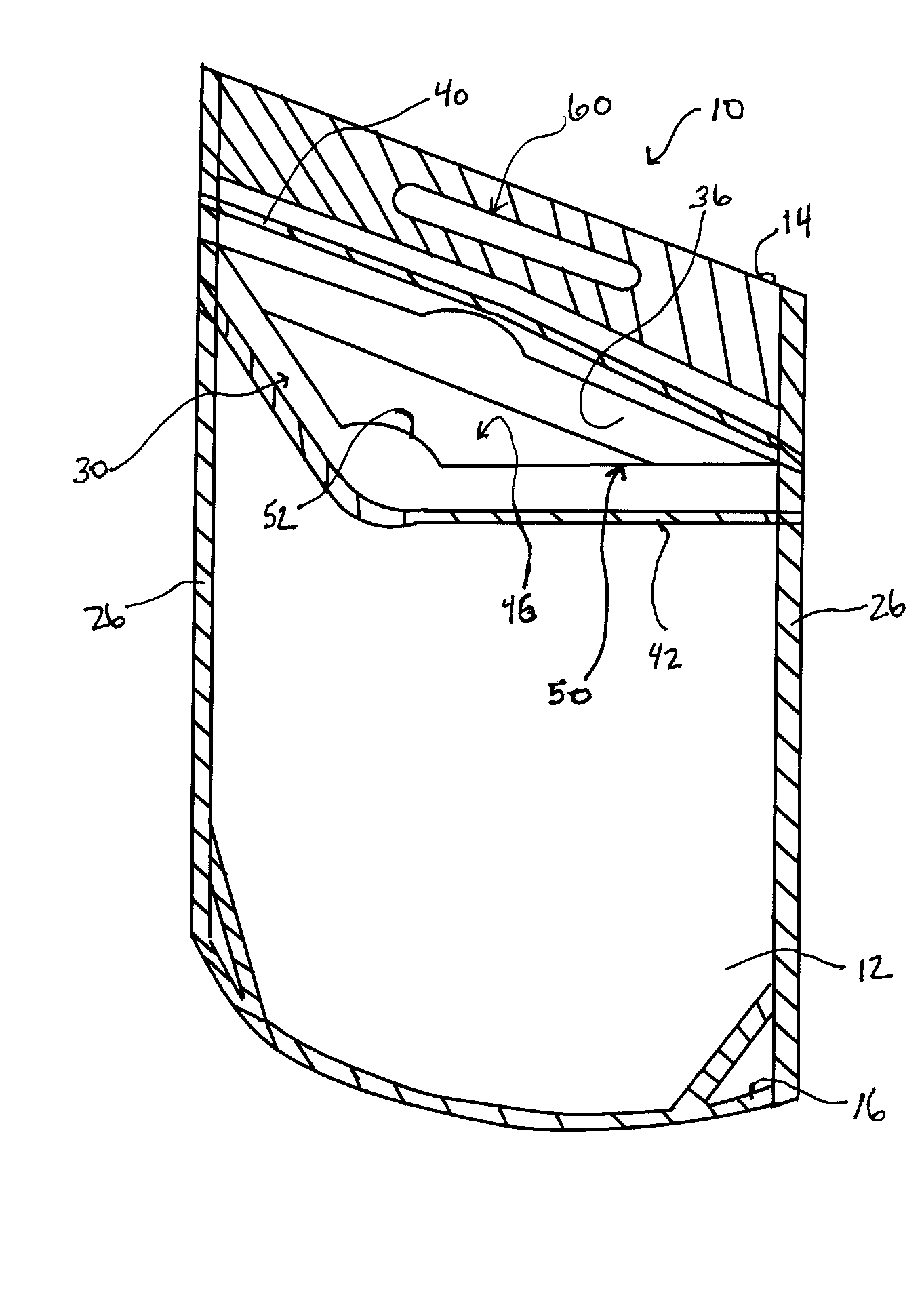

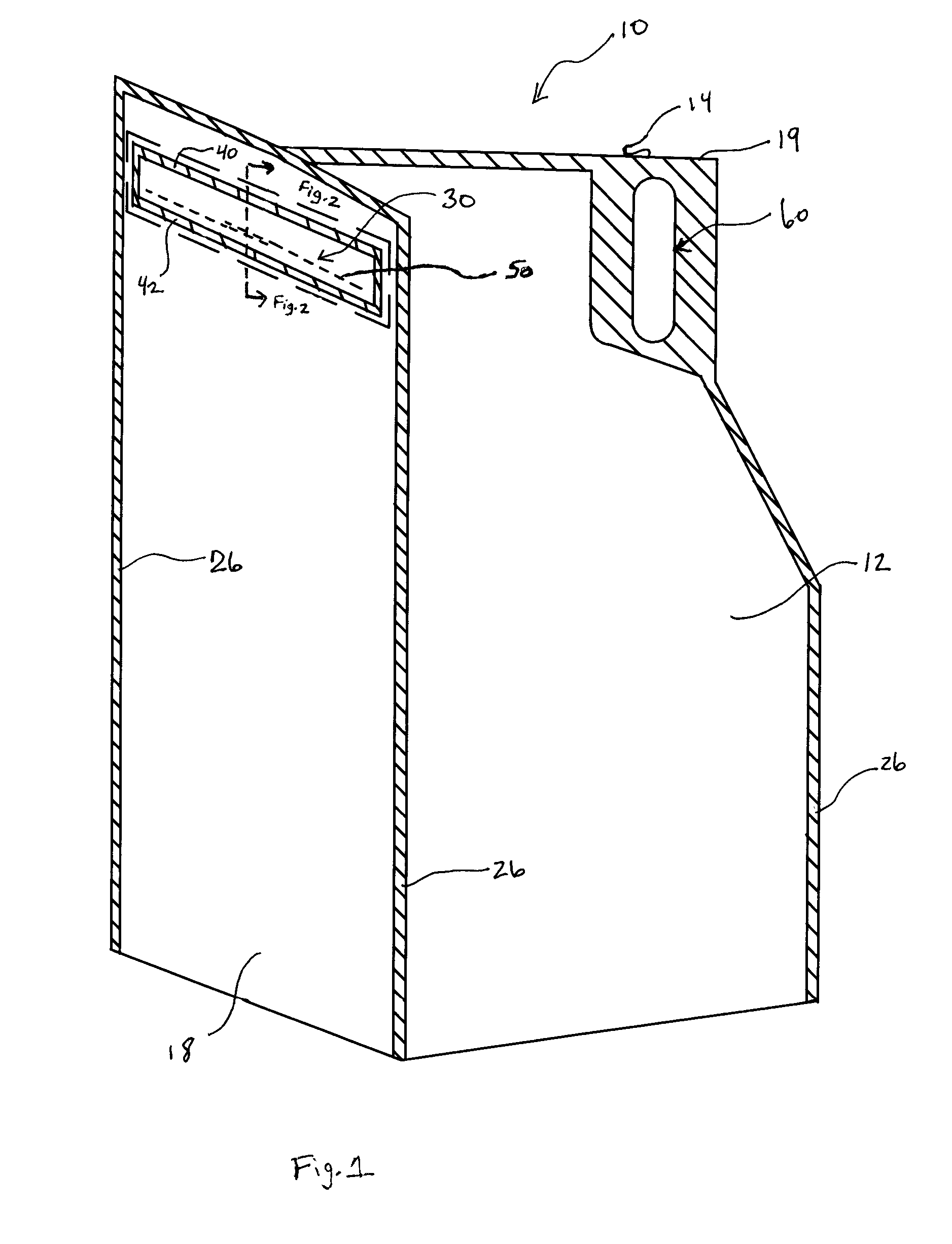

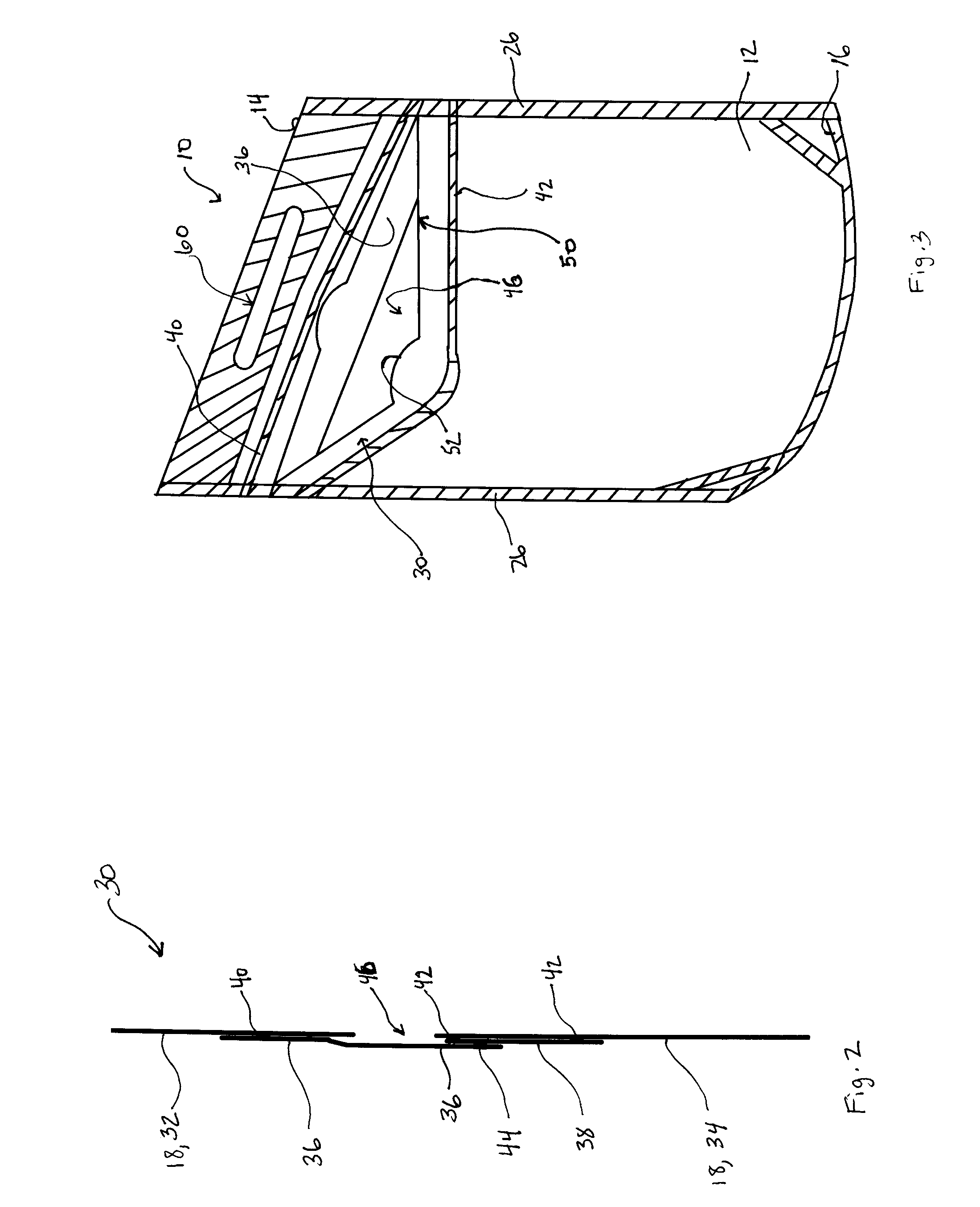

[0018]Referring generally to FIGS. 1-6a, a flexible package 10 in accordance with the present invention, and the steps for forming the flexible package 10, are shown. The package 10 generally includes a front panel portion 12 and a back panel portion 14. The package 10 can further include a bottom panel portion16 and one or more side panel portions 18. Panel portions 12-18 can be joined to form or define an inner cavity of the main package 10 for holding, transporting, or otherwise containing material contents. Each of the panel portions can include internal sealant surfaces. The joining of the front and back panels 12, 14 can create corresponding side or seal edges 26, and top 19 and bottom 21 seals. Alternatively, the panels can be formed of a single web material and folded or formed to define the distinct panel portions. The cross-hatching in the figures is generally used to denote sealing and / or panel edges or folds.

[0019]The package panel portions are generally constructed of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com