Method and system for layerwise production of a tangible object

a tangible object and production method technology, applied in the direction of additive manufacturing, coatings, pretreated surfaces, etc., can solve the problems of limiting the speed of the production process, affecting the production efficiency of tangible objects, so as to achieve the effect of fast production of tangible objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

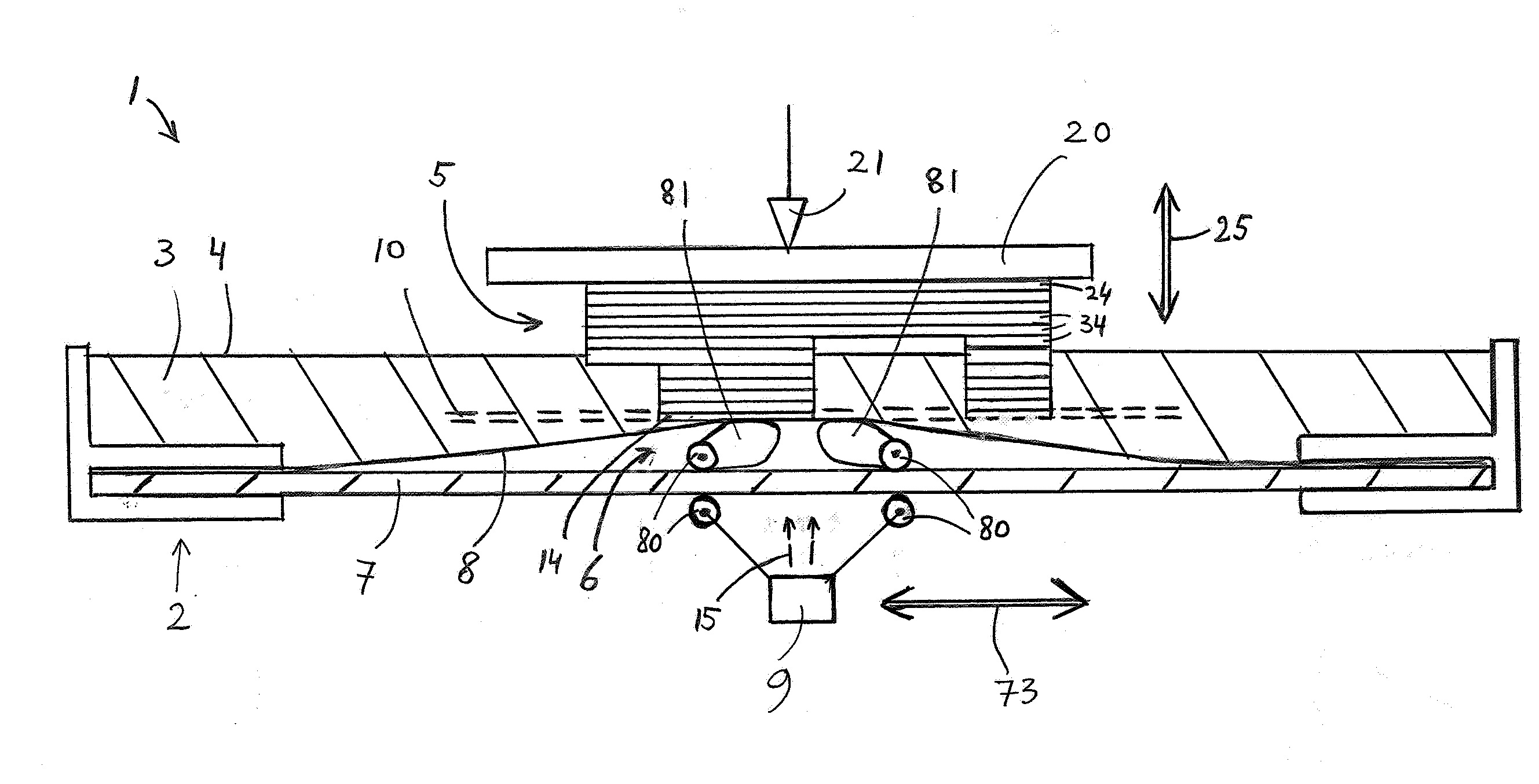

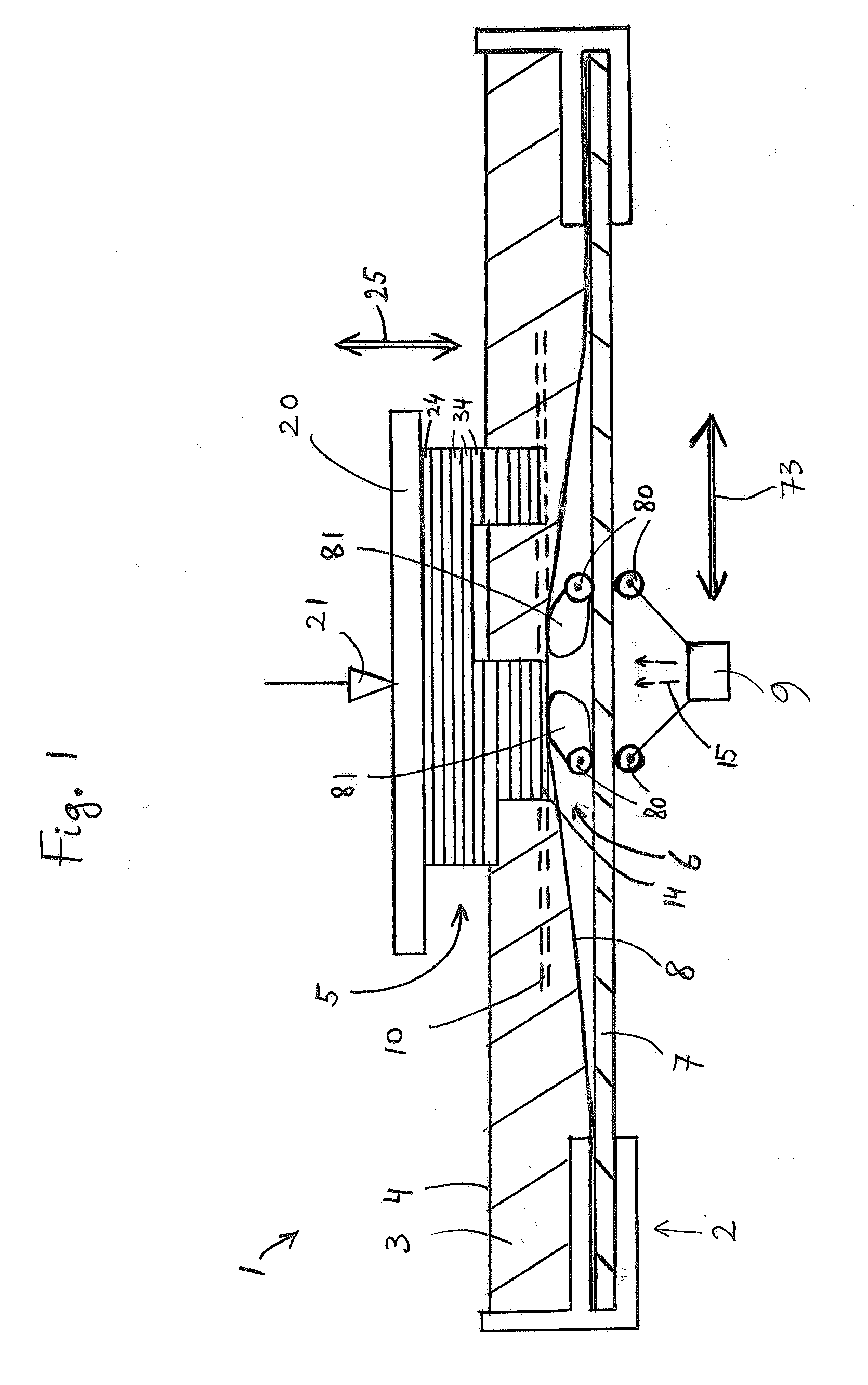

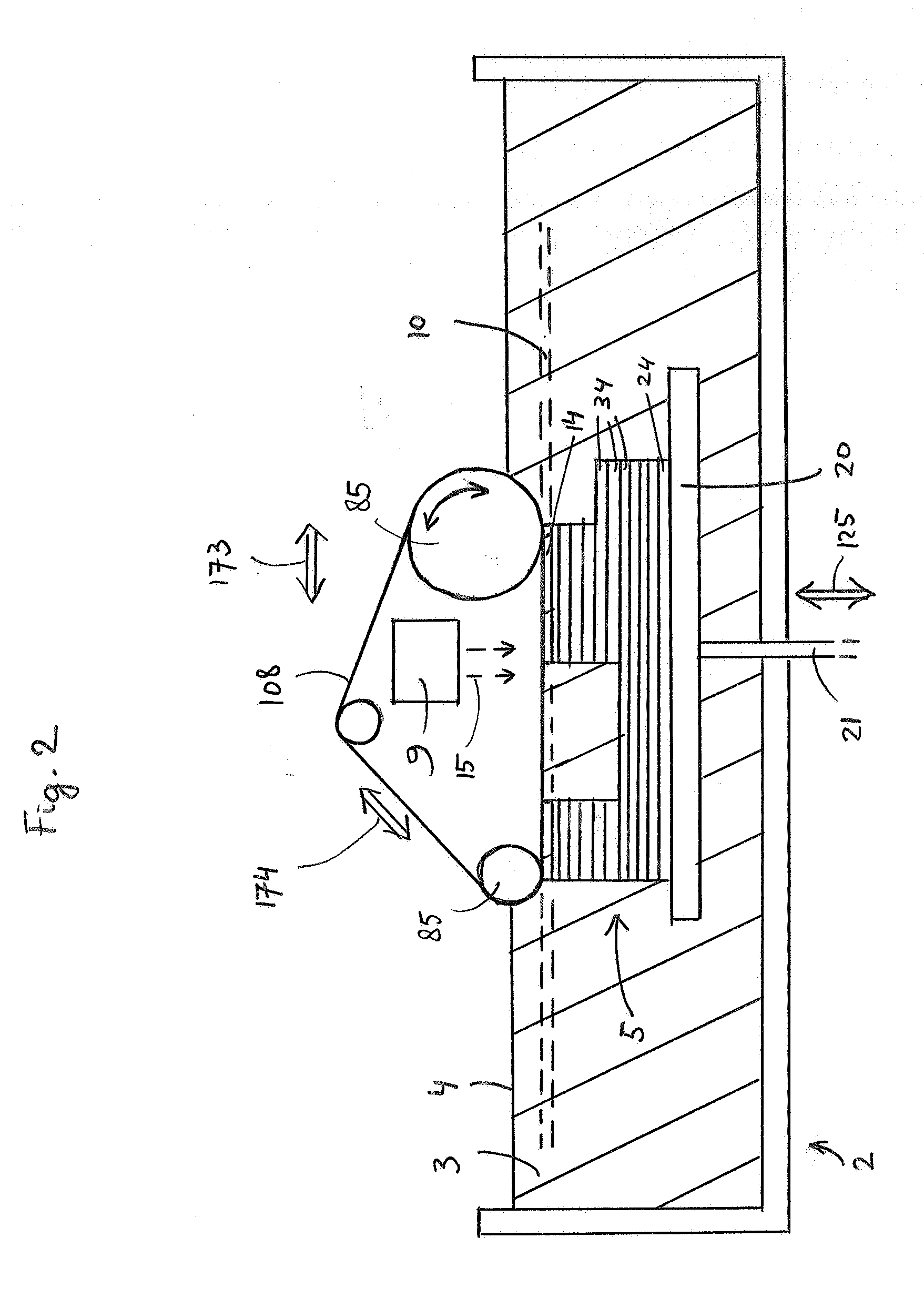

[0020]Each of the examples of FIGS. 1-5 relates to a system according to claim 9 that can perform an example of a method according to claim 1. In the respective figures sometimes the same reference signs are used for similar or identical parts or aspects of the systems.

[0021]Hence, each of the examples of FIGS. 1-5 relates to a system for layerwise production of a tangible object, the system comprising:

[0022]a liquid reservoir for containing a liquid therein;

[0023]a construction shape for being in contact with the liquid in the liquid reservoir;

[0024]solidifying means for solidifying a predetermined area of a layer of the liquid, said liquid layer adjoining the construction shape, so as to obtain a solid layer of the tangible object, the solid layer thus having a predetermined shape;

[0025]separating means for separating said solid layer from said construction shape;

[0026]moving means for moving, relative to one another, the separated solid layer and the construction shape to a prede...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com