Breech seal for air gun

a technology of air guns and seals, which is applied in the field of barrels and breech seals, can solve the problems of reducing smoothness and difficult shooting accuracy of air guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

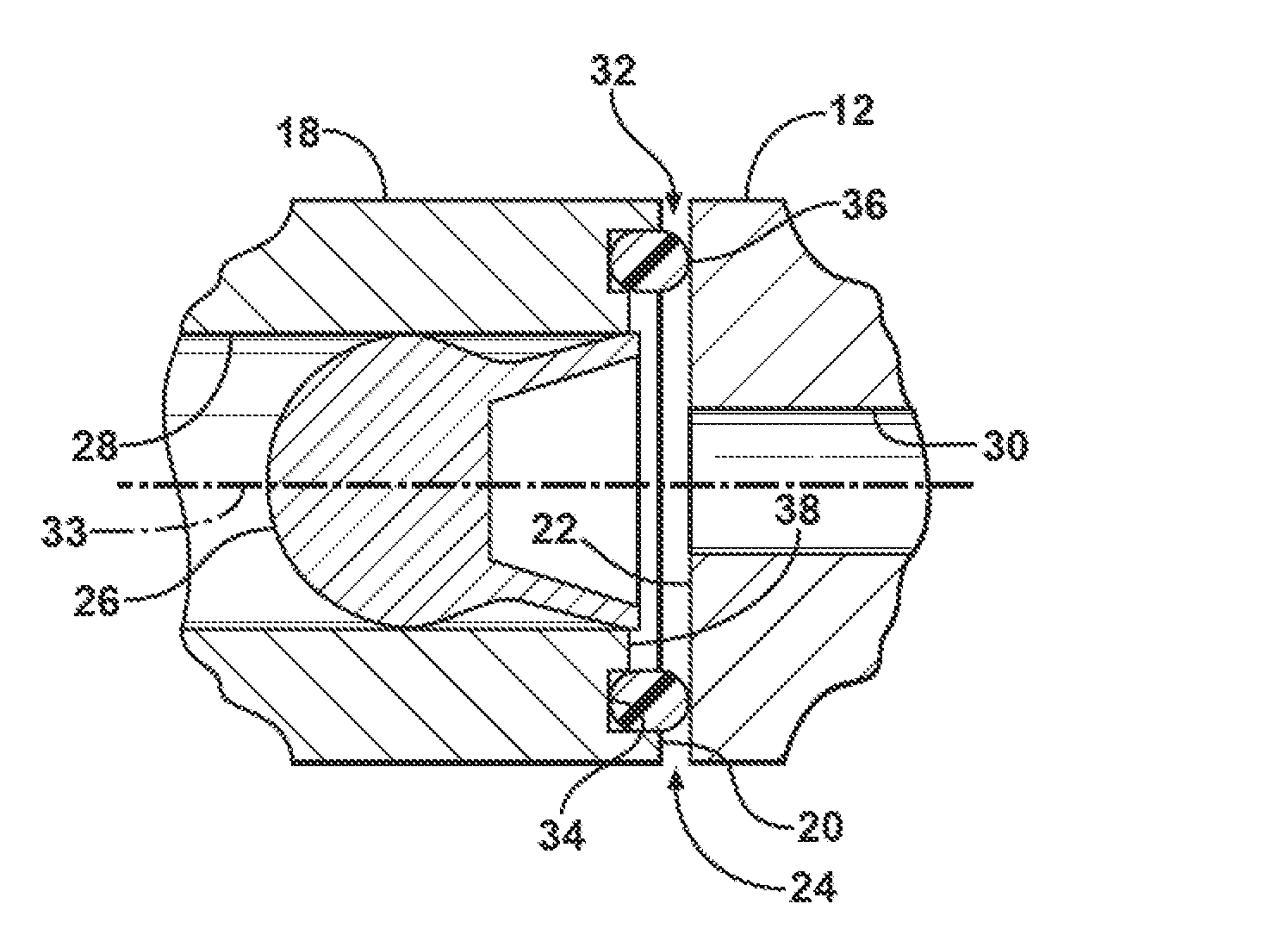

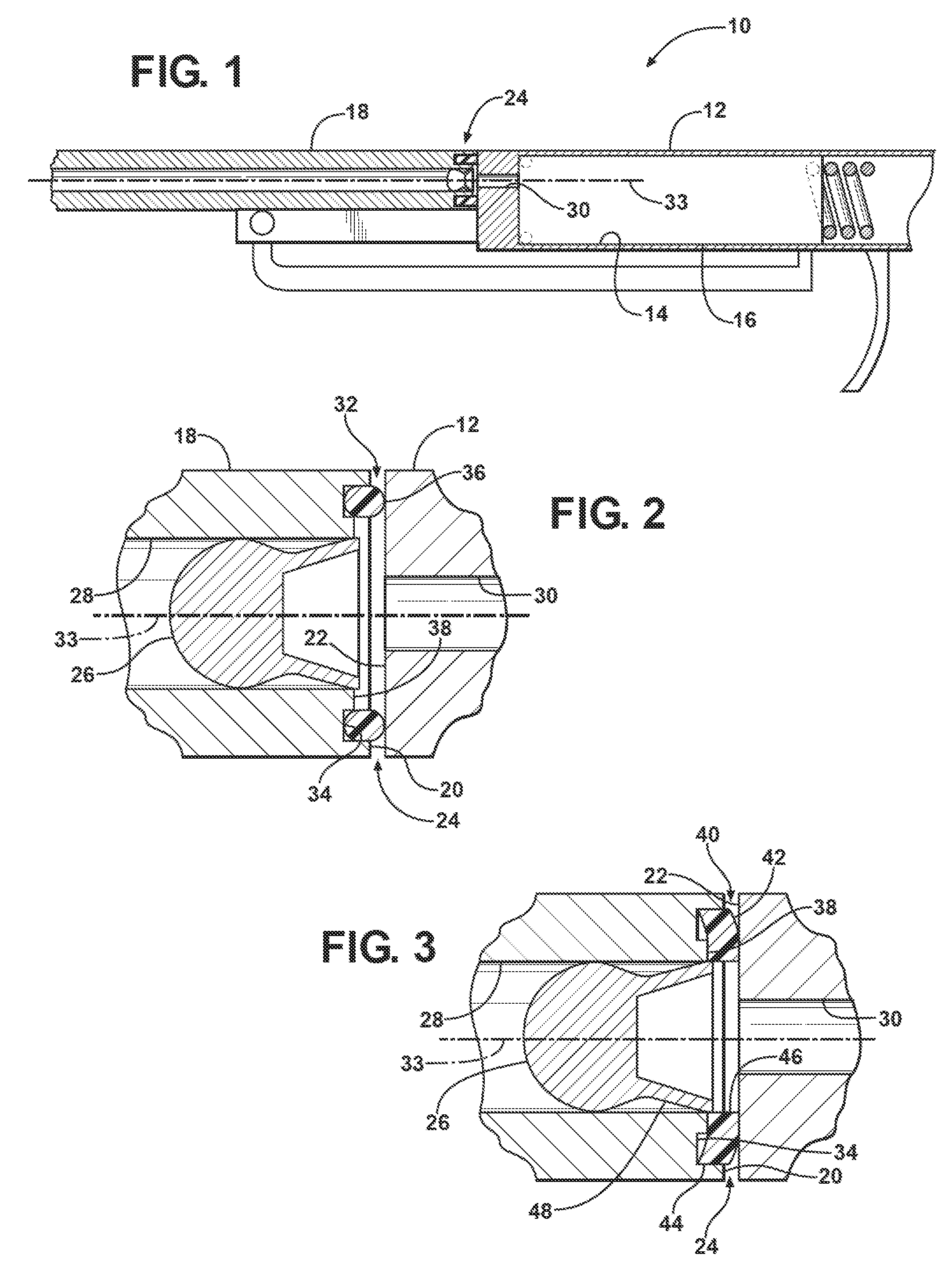

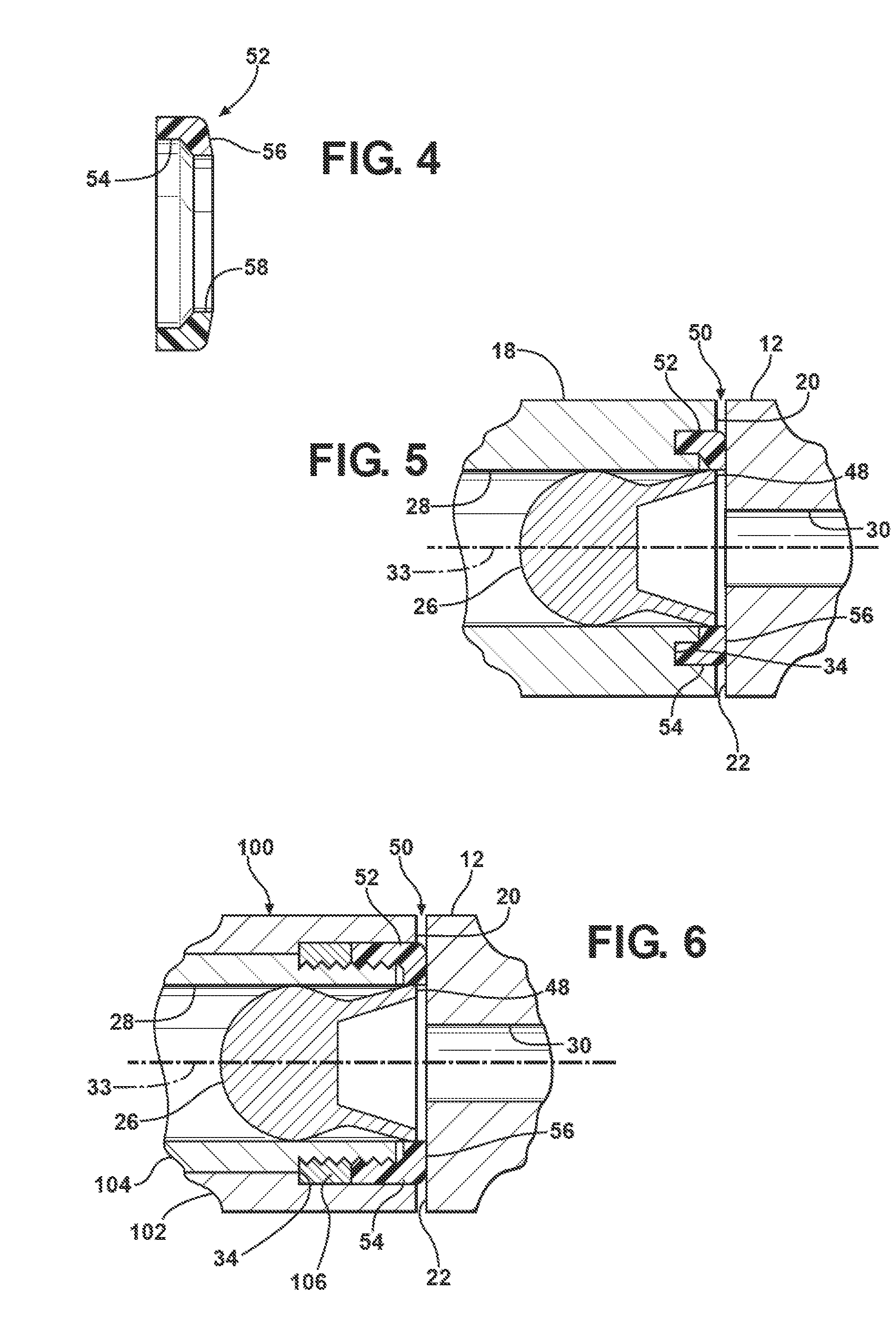

[0018]Referring to FIGS. 1 and 2, a break barrel air gun 10 includes a receiver 12 defining an internal compression chamber 14 for generating a quantity of compressed gas upon powered translation of a piston 16 within the chamber 14. The piston 16 may be powered by a coil spring, a gas spring, compressed gas, or some other power source suitable for the air gun 10. A barrel 18 is pivotally mounted on an end of the receiver 12, such that a barrel face 20 defined on a rearward end of the barrel 18 is pivoted away from a breech face 22, which is defined on a forward rend of the receiver 12, to provide access to a breech 24, whereby a pellet 26 can be loaded into the breech 24. When closed to place the barrel face 20 in general parallel-spaced opposition with the breech face 22, a barrel bore 28, which extends along a longitudinal axis 33, is placed in general axial alignment with a gas transfer port 30 that is defined in the breech face 22, by which compressed air is delivered from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com