Snow removal vehicle

a road vehicle and snow technology, applied in snow cleaning, way cleaning, construction, etc., can solve the problems of ineffective vehicle function, inability to displace reserves, and insufficient melting systems, so as to reduce the amount of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

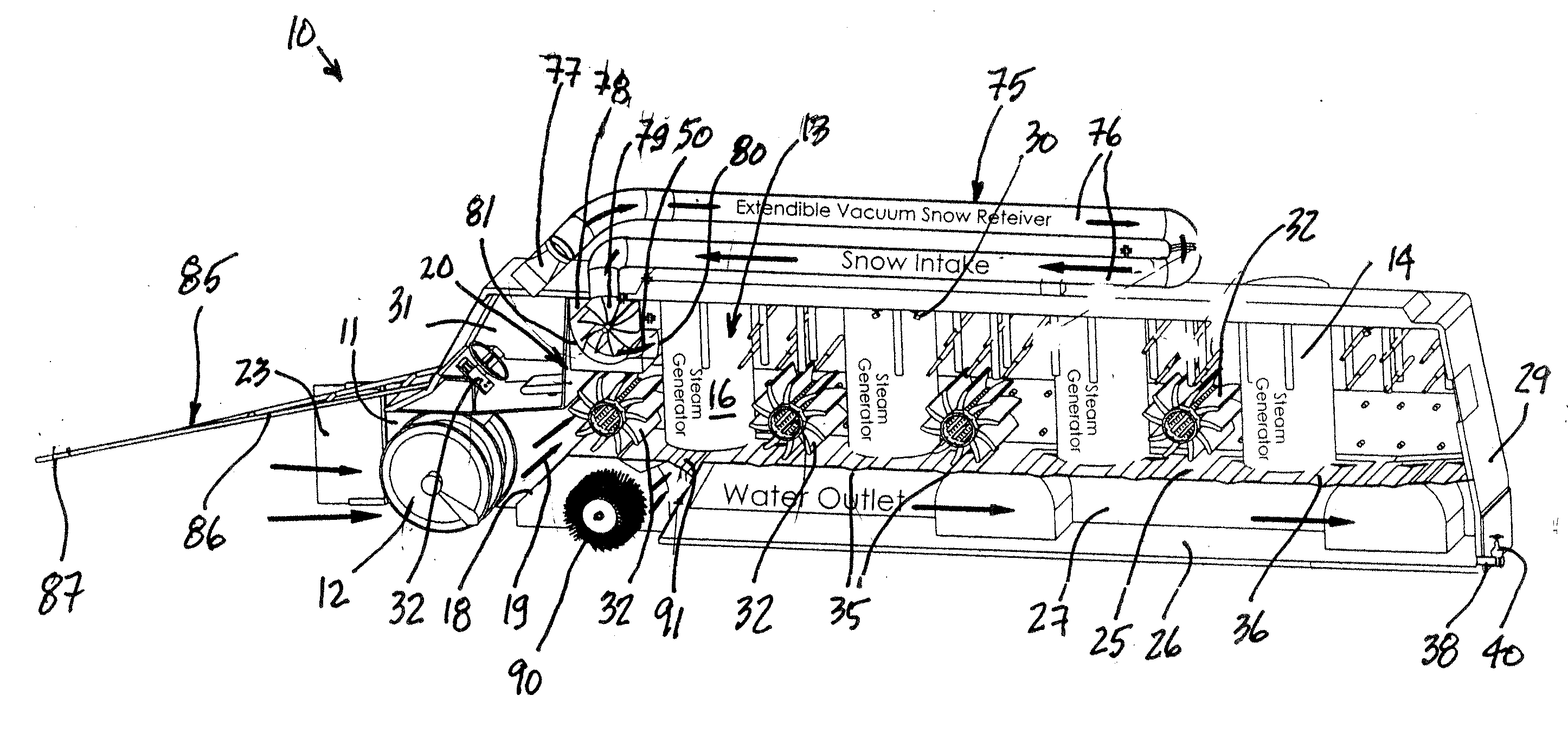

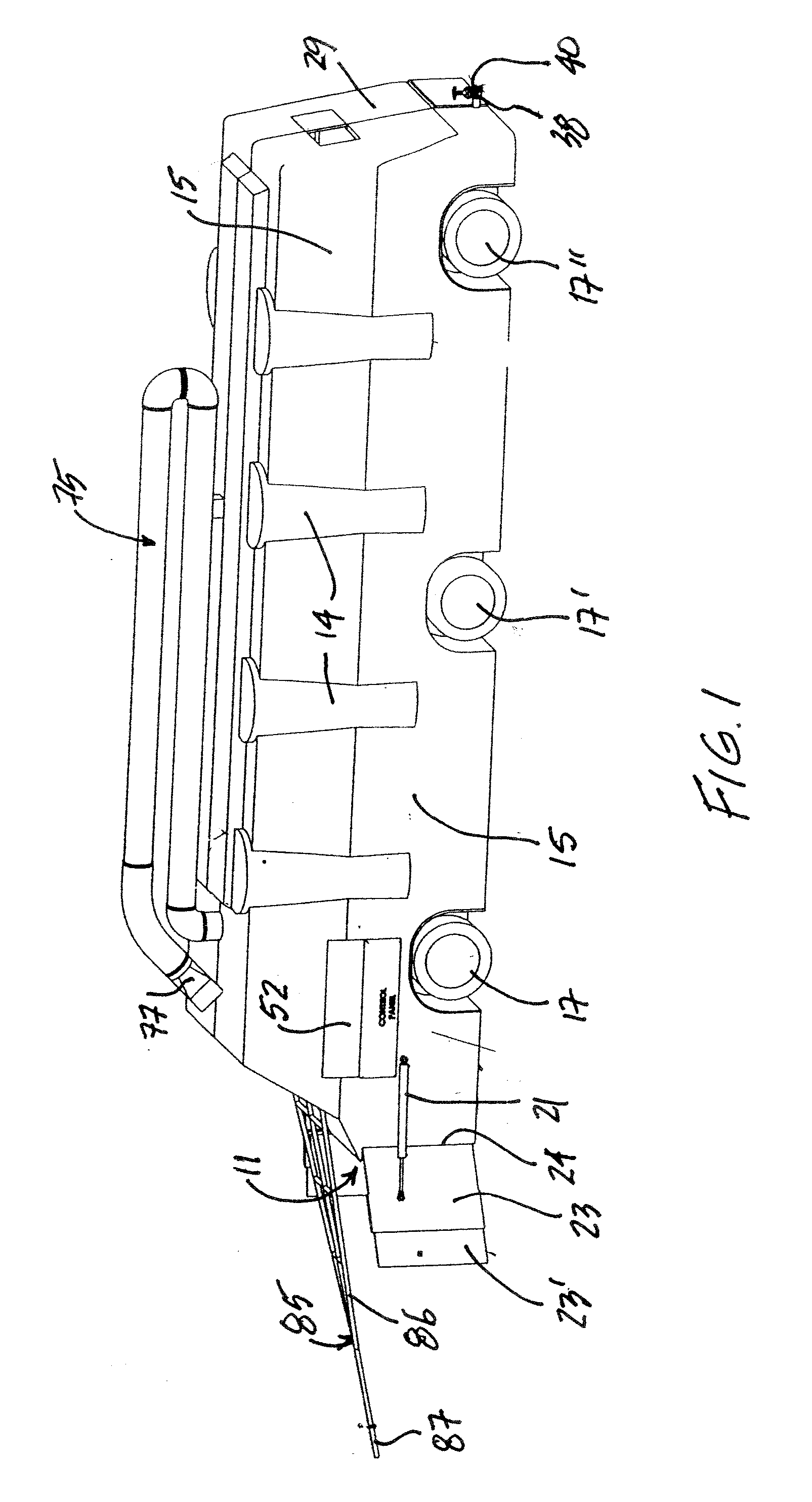

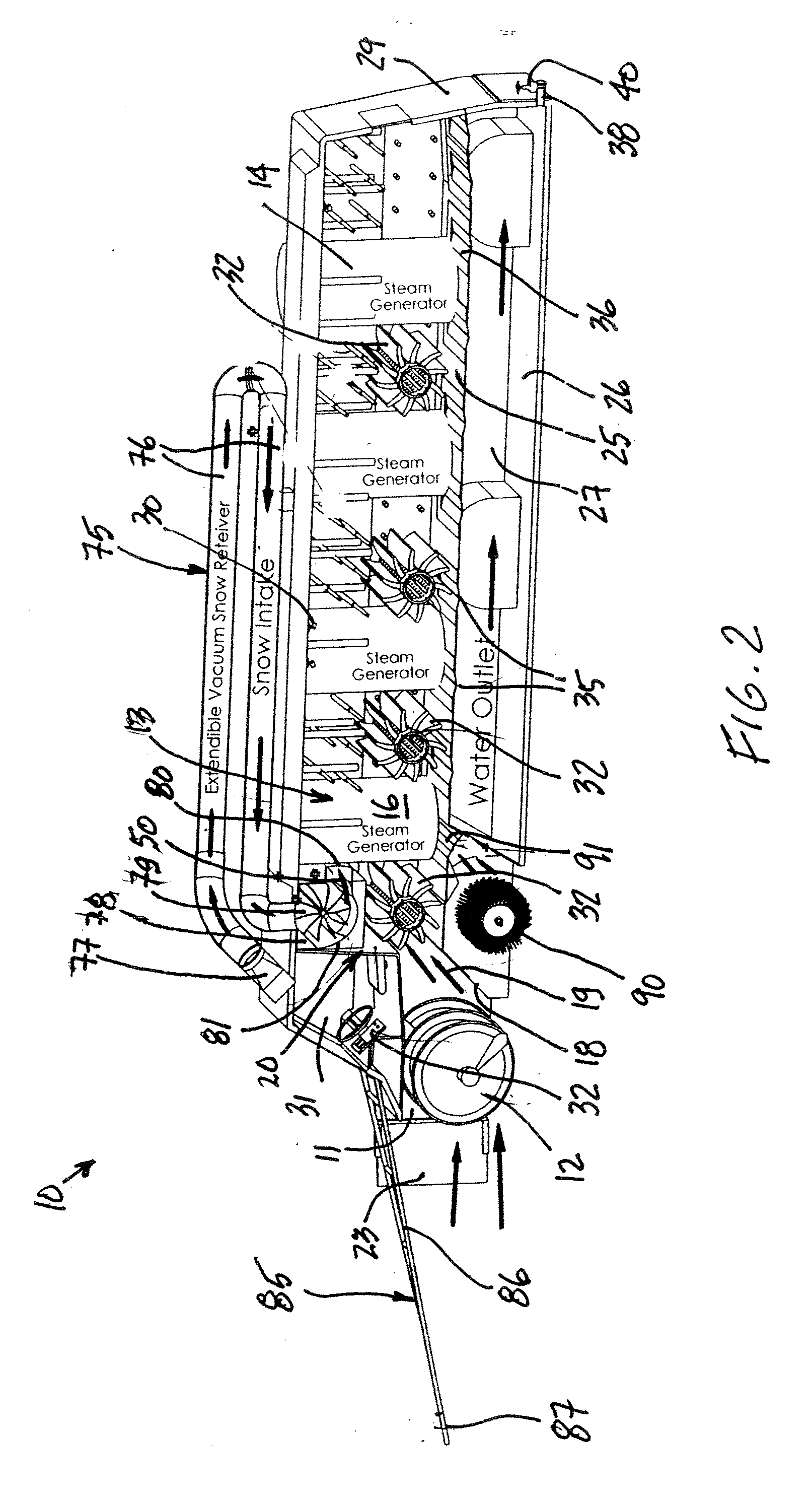

[0026]Referring to the drawings and more particularly to FIGS. 1 and 2, there is shown generally at 10 the snow removal vehicle of the present invention. As shown in FIGS. 1 and 2, the front end of the vehicle has a front entry opening 11 in which an auger means in the form of an auger screw 12 is mounted and driven at high speed whereby to eject snow positioned thereagainst rearwardly into the vehicle body 13. A plurality of steam generators 14 are mounted integral with the side walls 15 of the vehicle body 13. The vehicle body 13 defines therein an enclosed snow melting chamber 16 as shown in FIG. 2 and it communicates with the front entry opening 11. The vehicle body is also insulated. The vehicle 10 is supported on three sets of wheels 17, 17′ and 17″, but could also be supported on tracks or other propelling means, not shown.

[0027]As shown in FIG. 2, the front entry opening 11 is provided with a snow guiding ramp 18 rearwardly of the snow auger screw 12 whereby to guide project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com