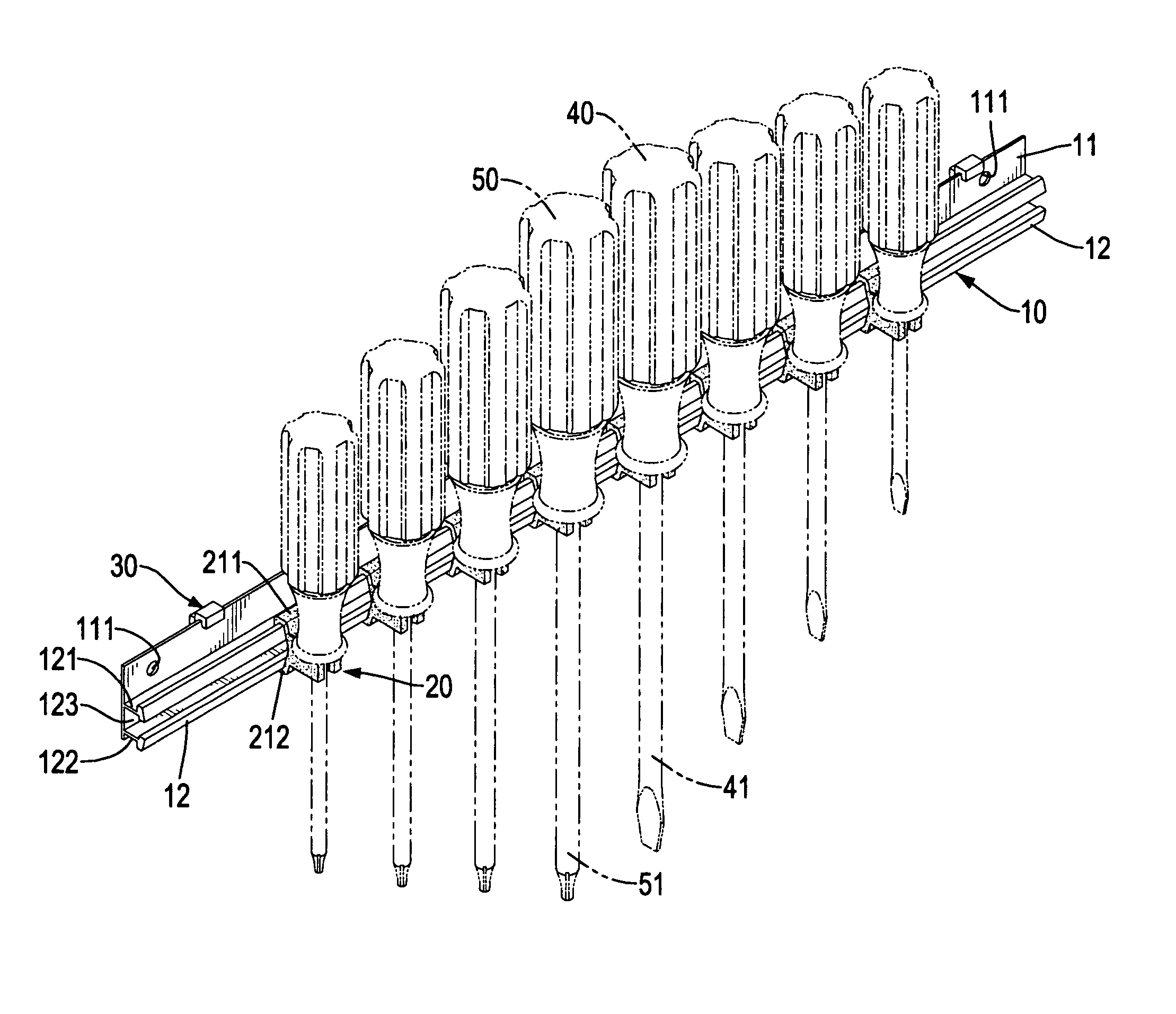

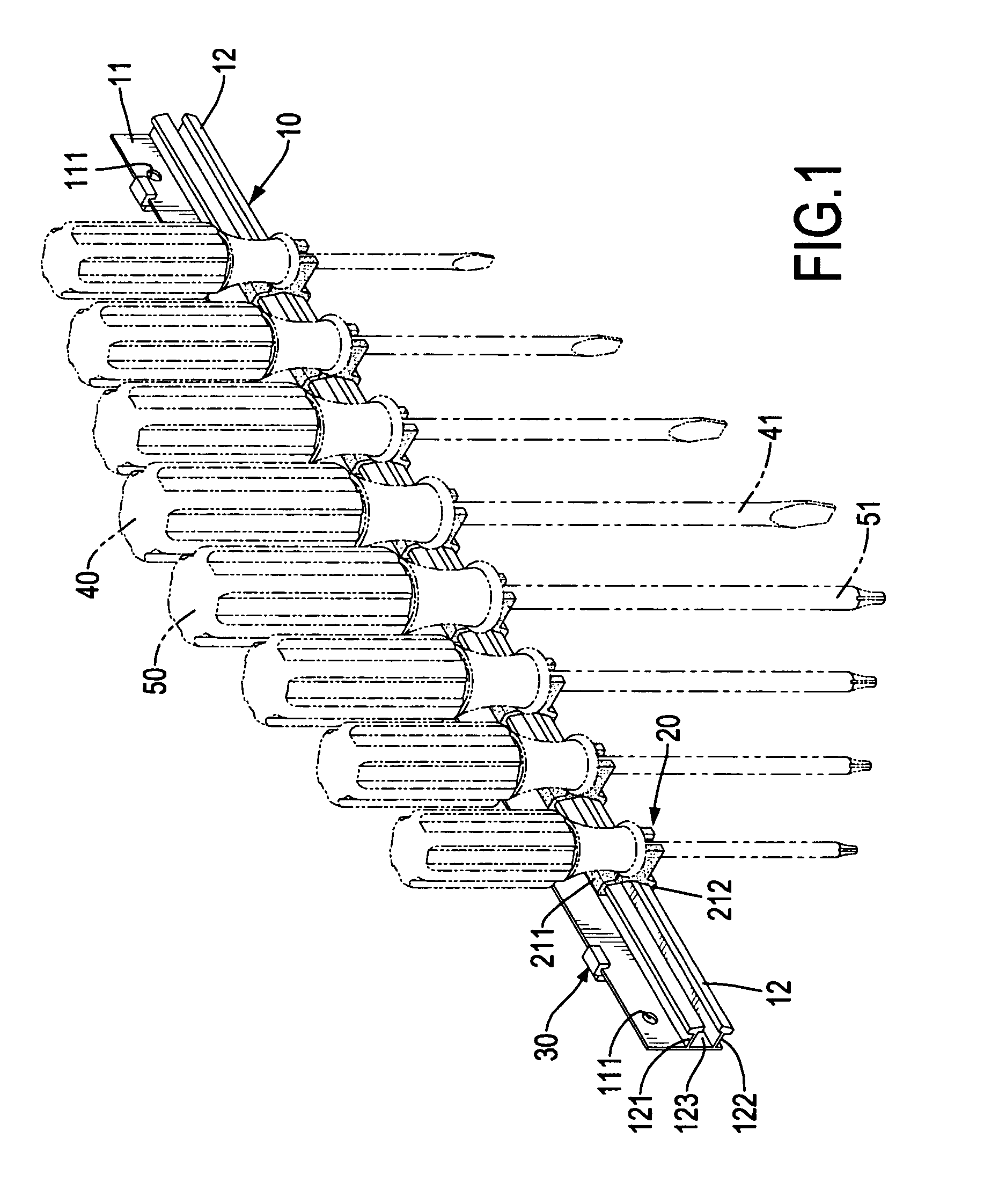

Tool suspension assembly

a technology of tool suspension and assembly, which is applied in the field of tool suspension assembly, can solve the problems of inconvenient and versatile use of the conventional tool suspension assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

In the first embodiment, each tool holder (20) may further have two connecting tabs (224) and a reinforced tab (225). The connecting tabs (224) are respectively connected to the lateral tabs (223) and to the clamp (21) of the tool holder (20). The reinforced tab (225) is laterally formed between and connected to middle portions of the clamp (21), the tool mount (22) and the connecting tabs (224). With the arrangement of the reinforced tab (225), the structural strength of the tool holder (20) is enhanced. With the arrangement of the connecting tabs (224) and the reinforced tab (225), the tool mount (22) is connected to the clamp (21).

second embodiment

With reference to FIGS. 7 to 9, in the second embodiment, each tool holder (22A) further has two connecting tabs (224A) mounted between the tool mount (22A) and the clamp (21A) of the tool holder (20A) to connect the tool mount (22A) to the clamp (21A).

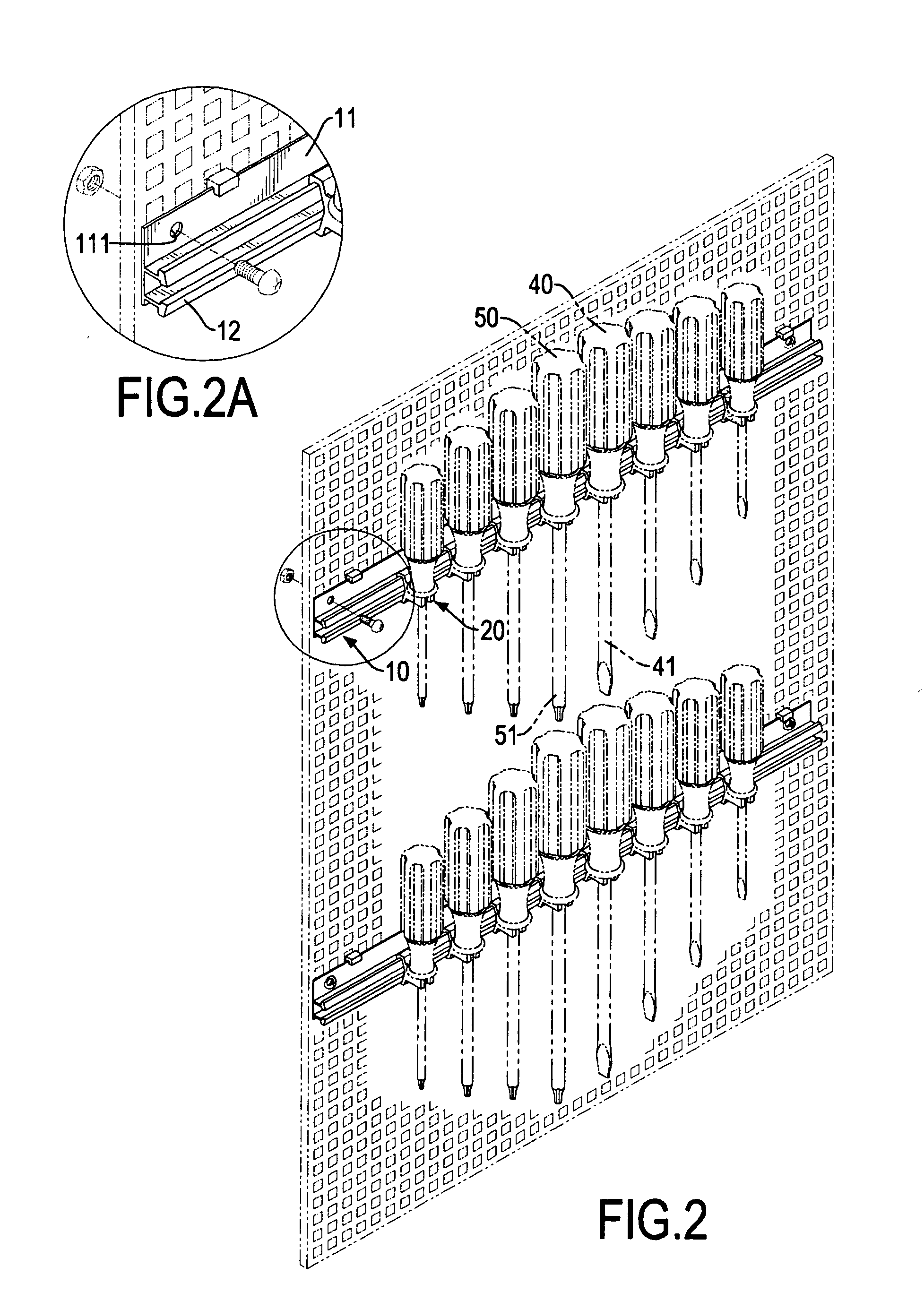

With reference to FIGS. 6 and 6A, the hanging elements (30) are attached to the rear side of the back board (11), and each hanging element (30) having a hanging board (31), two base hooks (32) and a panel hook (33). The hanging board (31) has a top, a bottom, a front side attached to attached to the rear side of the back board (11) and a rear side. The base hooks (32) are formed respectively on the top and bottom of the hanging board (31), protrude from the front side of the hanging board (31) and are mounted over and hook on a top edge and a bottom edge of the back board (11) in respective. The panel hook (33) is formed on and protrudes from the rear side of the hanging board (31) to be inserted into or engage a hole defined in a han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com