Tie-down cleat for a moving vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

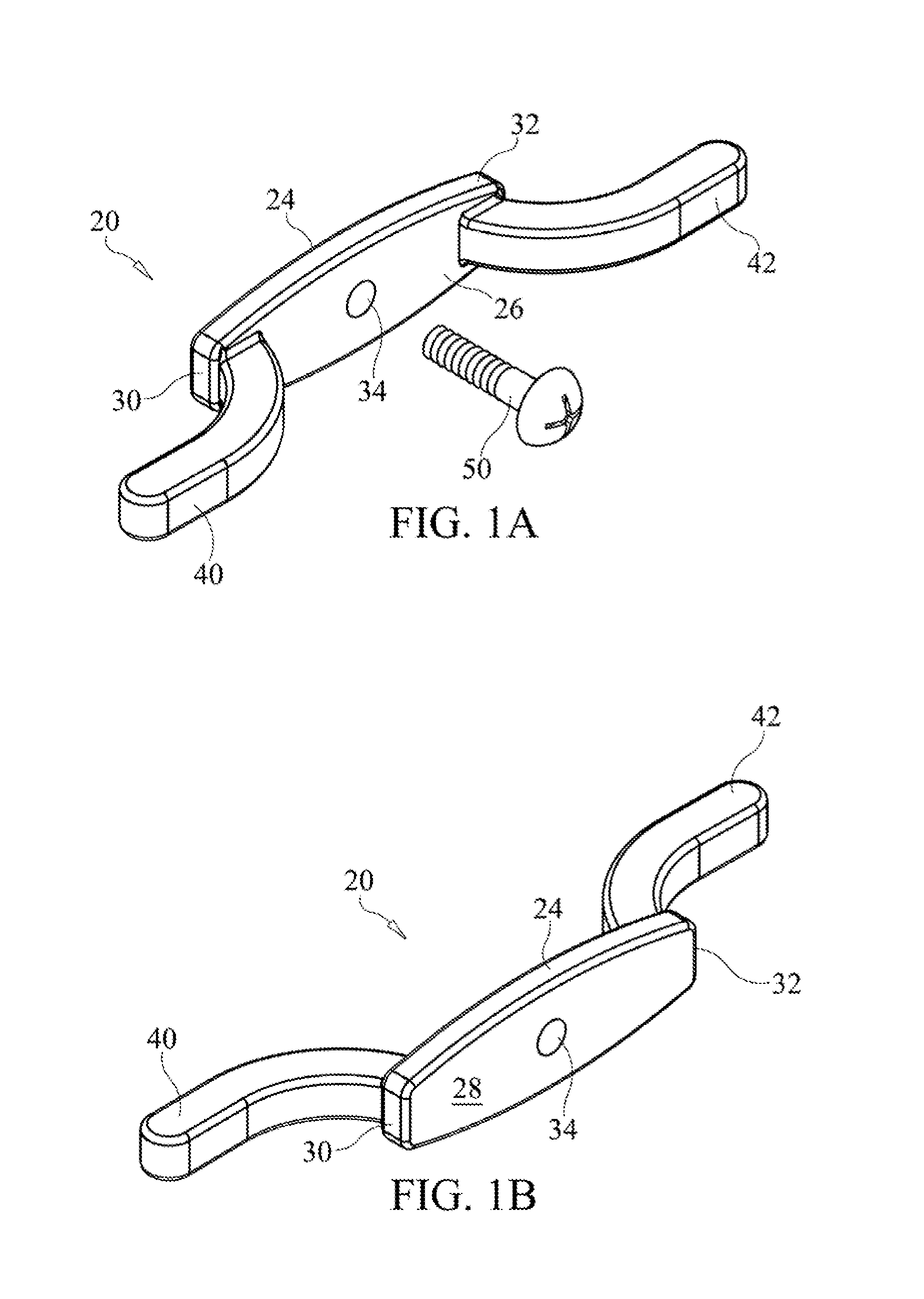

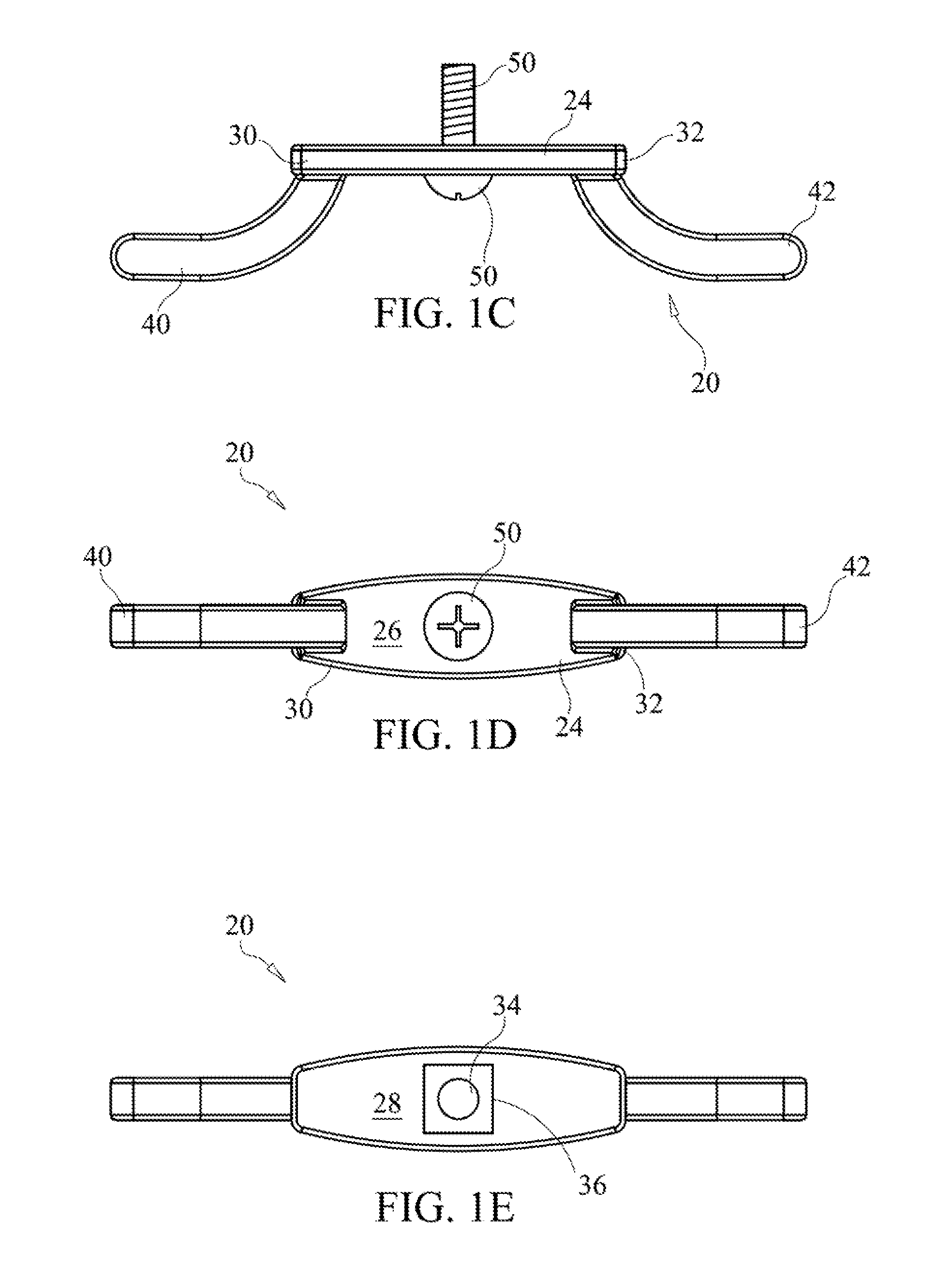

[0029]A first embodiment of the present invention is illustrated in FIG. 1a though FIG. 1e and is generally designated as vehicle secured cleat-like member 20. Cleat-like member 20 includes a base portion 24 having a top surface 26, a bottom surface 28, a first end 30 and a second end 32. An aperture 34, which can be threaded, is defined through base portion 24. A nub or protrusion, or other downward member 36, can extend downward from bottom surface 28 and is preferably located by or adjacent aperture 34. In one non-limiting embodiment protrusion 36 can be a square-like member extending from bottom surface and having a circular passageway in communication with aperture 34 to effectively expand the length of aperture 34. Protrusion 36 helps to prevent or minimize rotation or turning of cleat-like member 20 when it is secured to the vehicle by one of the license plate screws 50 (with “screws” being defined as noted above). When cleat-like member 20 is properly attached, protrusion 36...

Example

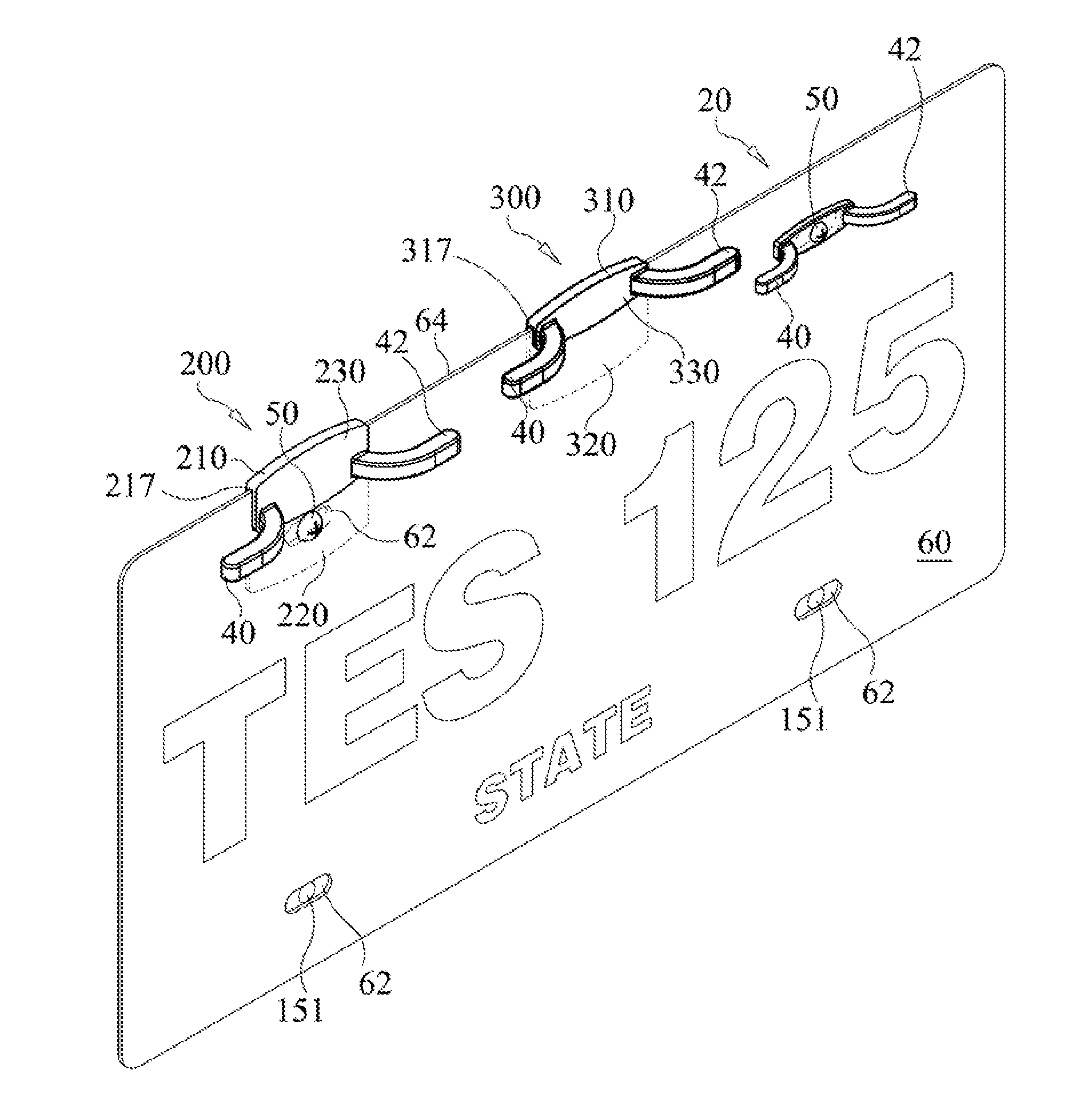

[0033]As seen in FIGS. 4 and 5, a second embodiment is shown as cleat-like member 200, which is provided with similar flange members 40 and 42 disposed at first end 30 and second 32 of base 210. Base 210 is provided with a bottom surface 212 and top surface 214. A slot 216 is formed in base 210 to define a first or bottom portion 220 and a second or top portion 230. Bottom portion 220 is preferably extended in length as compared to top portion 230, and along with slot 216, base 210 can be substantially J-shaped, and when secured to vehicle 150 can be a substantially inverted “J” in shape. It should be recognized that other shapes can be used for base 210 (i.e. substantially “U” shaped, etc.) and all are considered within the scope of the invention. An aperture 222 can be provided through bottom portion 220.

[0034]To secure cleat-like member 200 to a vehicle 150, the relevant license plate screw 50 is unscrewed (if currently screwed in) and aperture 222 is aligned with the chosen rece...

Example

[0036]As seen in FIGS. 4 and 6, a third embodiment is shown as cleat-like member 300 which eliminates aperture 34 or aperture 222. Cleat-like member 300 is provided with similar flange members 40 and 42 disposed at first end 30 and second 32 of base 310. Base 310 is provided with a bottom surface 312 and top surface 314. A slot 316 is formed in base 310 to define a first or bottom portion 320 and a second or top portion 330. Bottom portion 320 is preferably extended in length as compared to top portion 330, and along with slot 316, base 310 can be substantially J-shaped, and when secured to vehicle can be a substantially inverted “J” in shape. It should be recognized that other shapes can be used for base 310 (i.e. substantially “U” shaped, etc.) and all are considered within the scope of the invention.

[0037]To secure cleat-like member 300 to a vehicle 150, the relevant license plate screw(s) 50 is(are) at least partially unscrewed (if currently screwed in) to loosen license plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com