Tunnel multi floor

a tunnel and multi-floor technology, applied in the direction of tunnel lining, shaft lining, underground chambers, etc., can solve the problems of inability to meet the diameter requirements of existing tunnel boring machines, and the problem of also affecting the diameter of existing tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

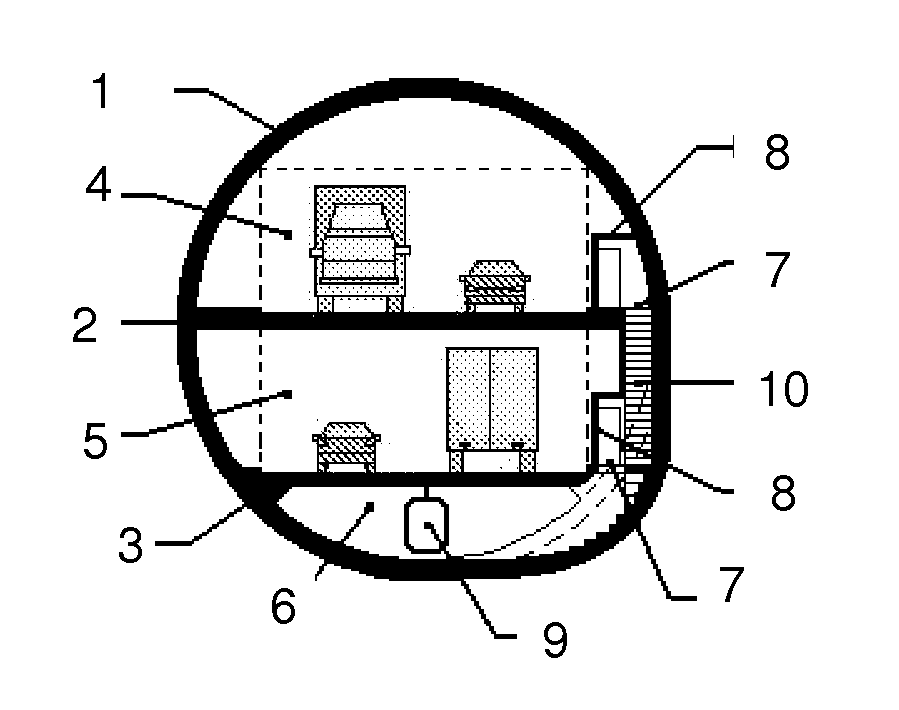

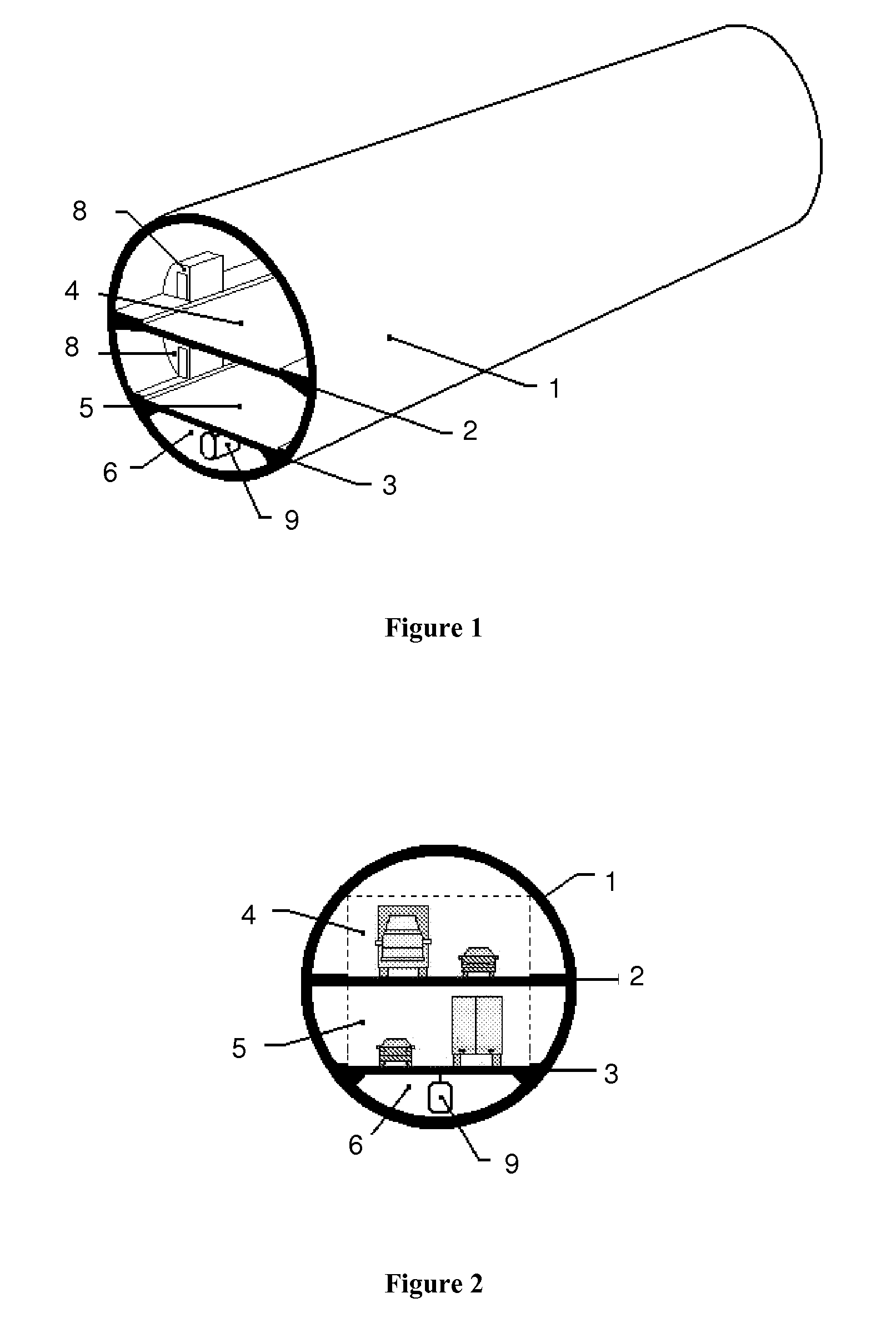

[0016]A tunnel boring machine excavates soil and places precast segments, which are clamped together, in order to form the wall of the tunnel 1, which is circular shaped.

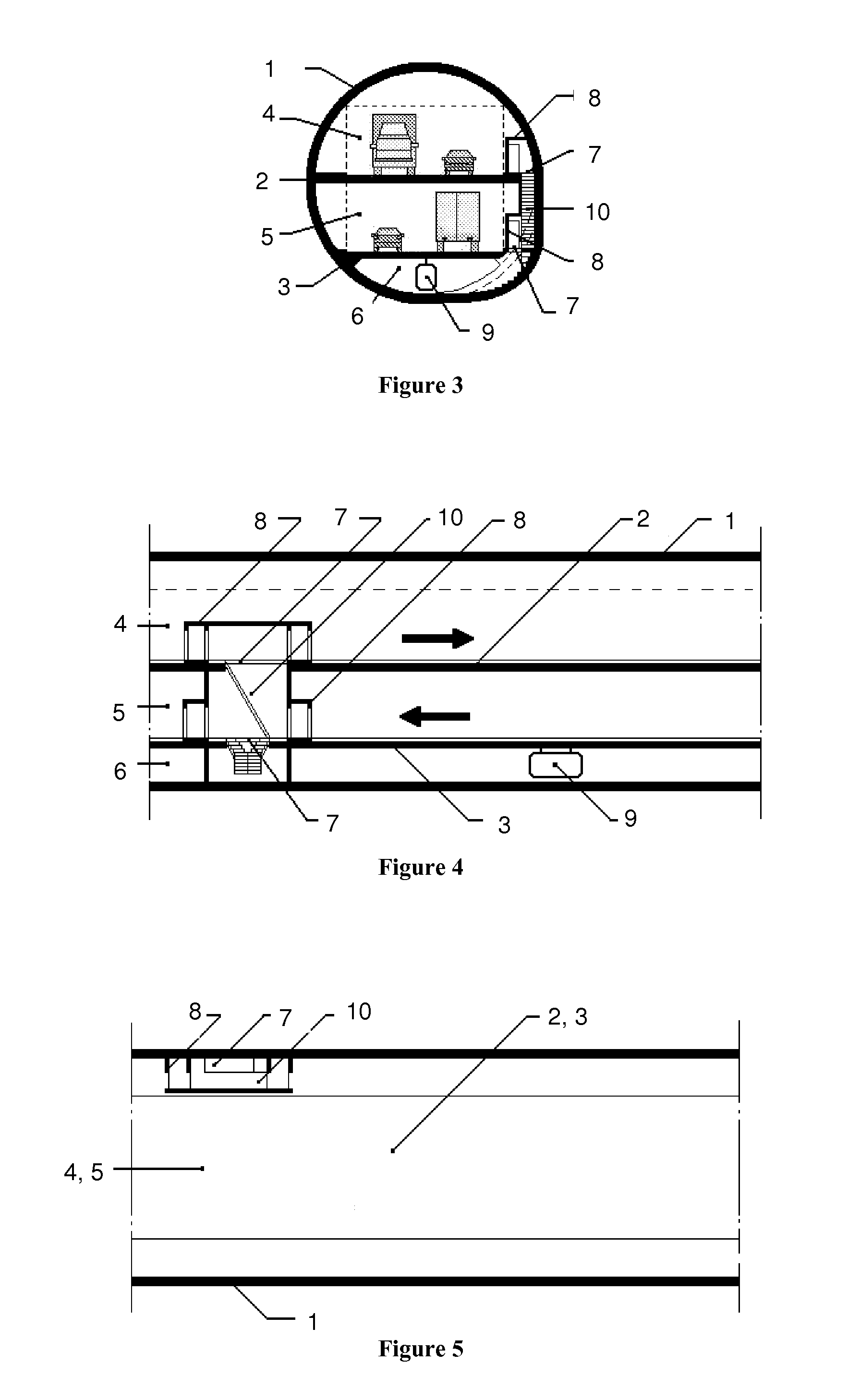

[0017]Referring to FIGS. 1-5, inside of the tunnel 1 two slabs 2, 3 are executed, along the full width of the tunnel, one placed roughly at half the height of the tunnel and the other placed slightly above the bottom of the tunnel. This creates three isolated and independent galleries, one on top of another: two substantially identical roadway galleries 4, 5, one for each way of traffic, and a service gallery 6.

[0018]On the slabs 2 and 3, openings 7 will be arranged, placed close to the circular wall of the tunnel 1, in one or in both sides of the tunnel. The openings will be regularly spaced, protected with fireguard devices 8 of box type, which will be provided with escape doors. The fireguard devices 8 are located on both slabs 2 and 3, and are connected through closed vertical access galleries 10, which are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com