Colored golf ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

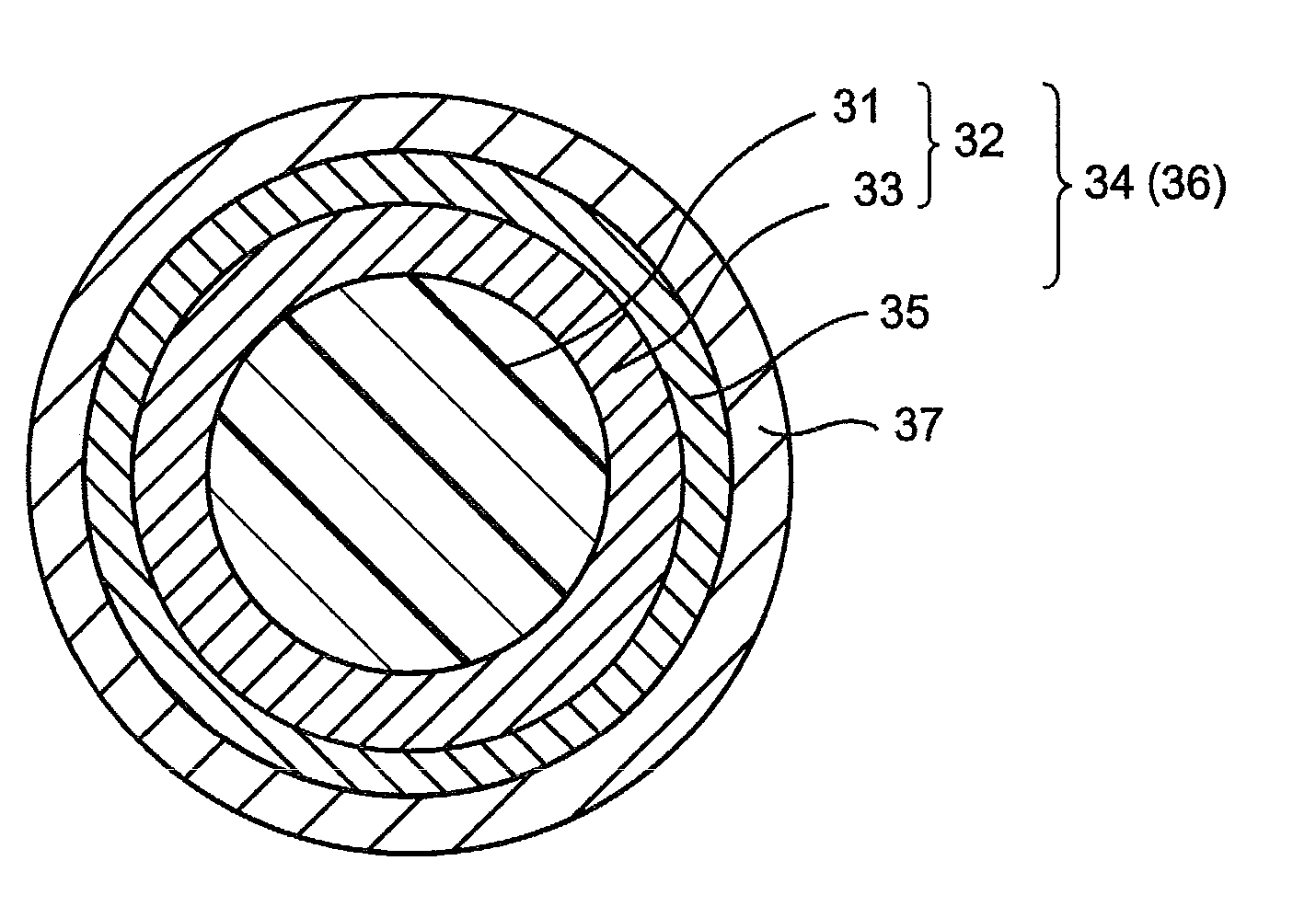

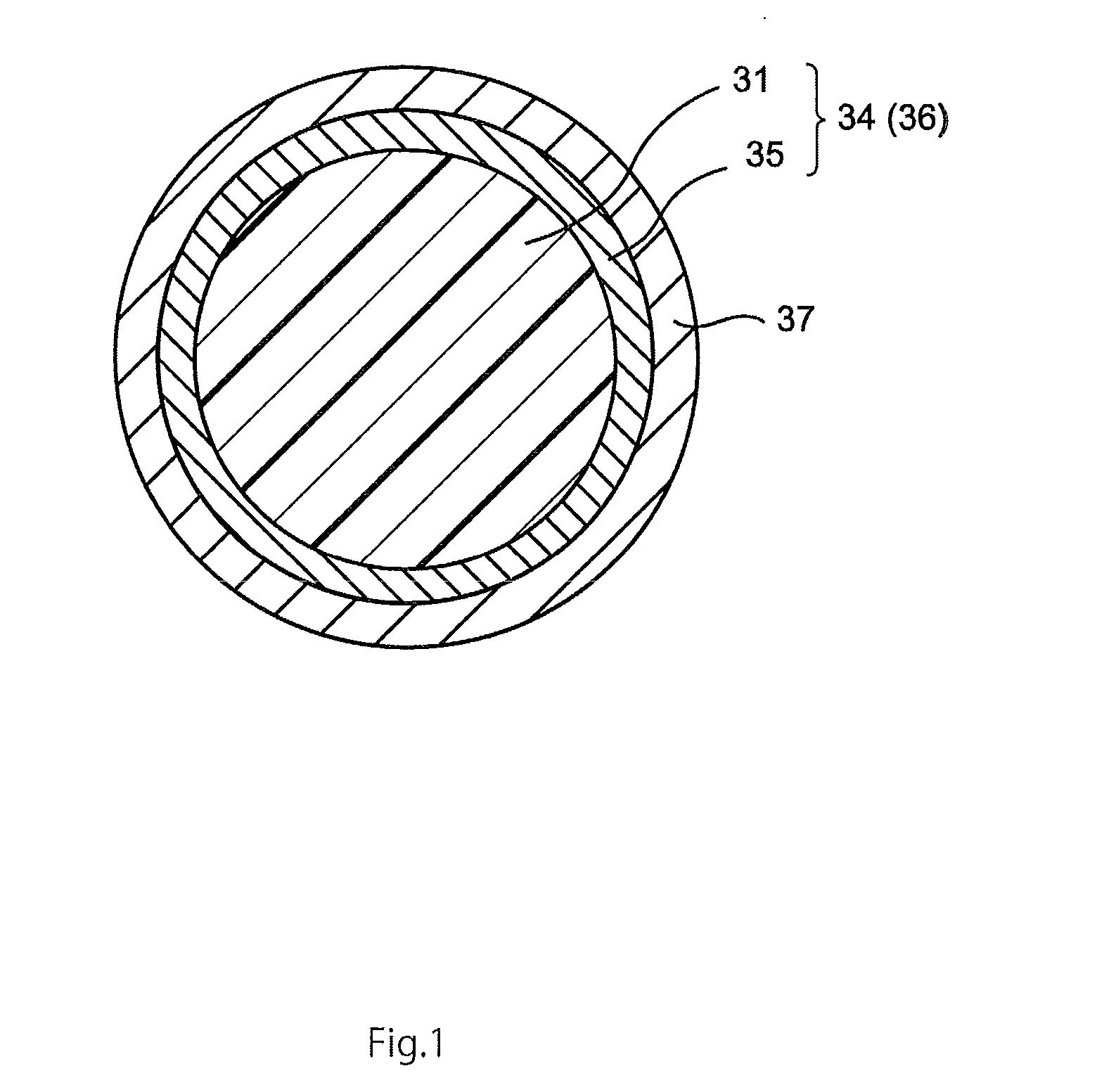

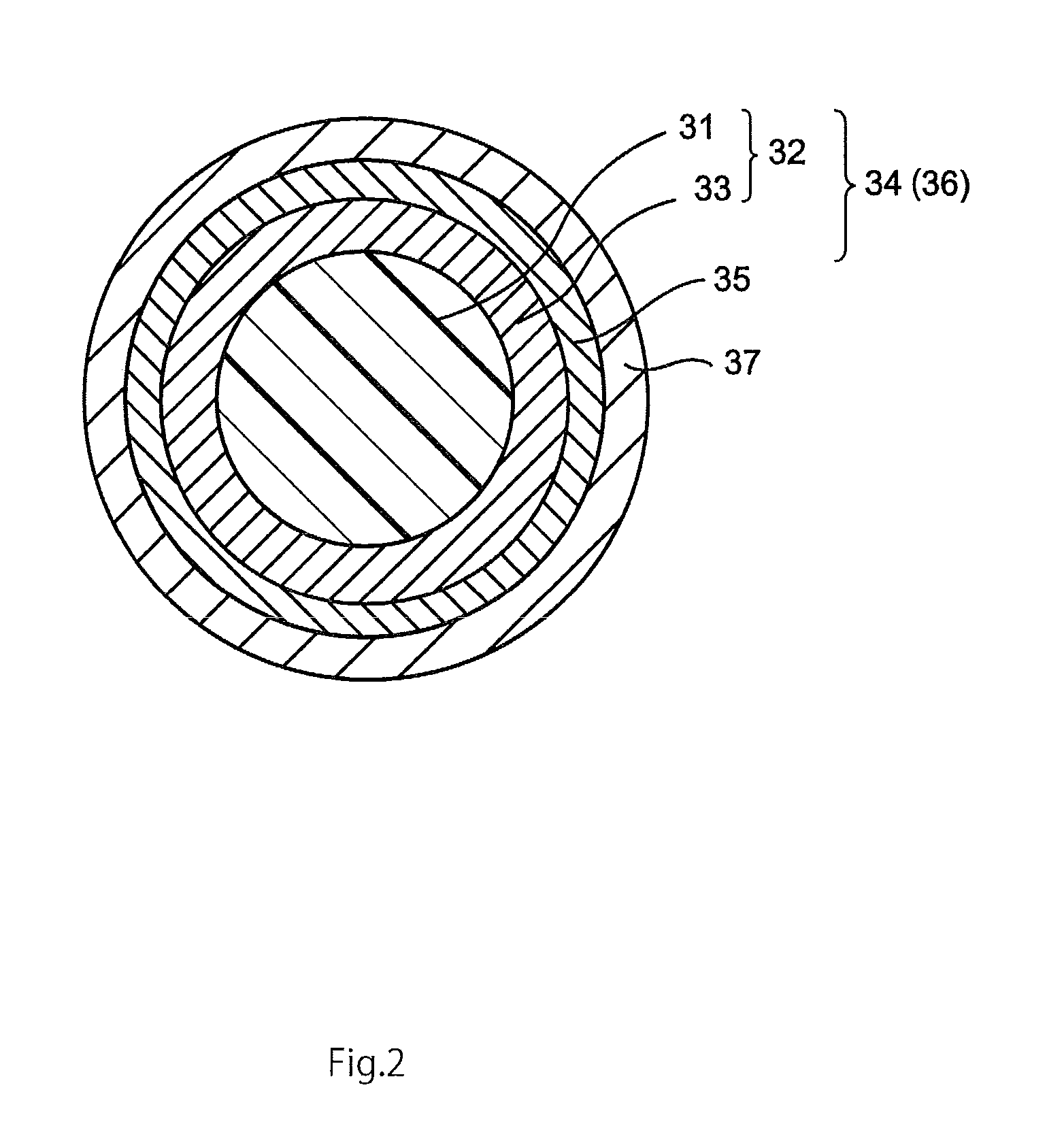

Image

Examples

examples

[0156]Hereinafter, the present invention will be described in detail by way of example. The present invention is not limited to examples described below. Various changes and modifications can be made without departing from the spirit and scope of the present invention.

[Evaluation]

(1) Color Tone

[0157]Color tones of the intermediate layers, covers and paint layers were measured using a color difference meter named “CR-221” manufactured by MINOLTA CO using a pulse xenon lamp as a light source. The measurement was conducted on ball, not a slab. That is, the color tone of the intermediate layer was measured in a state of the core where the intermediate layer was formed on the center. The color tone of the cover was measured in a state of the golf ball body where the cover was formed on the core. The color tone of the paint layer was measured in a state of the golf ball where the paint layer was formed on the golf ball body.

(2) Surface Hardness of Center, Inner core and Outer Core (JIS-C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com