Pipe guide for snubbing units

a technology of snubbing unit and pipe guide, which is applied in the direction of fluid removal, drilling accessories, and accessories for drilling wells. it can solve the problems of reducing affecting the efficiency of snubbing operations, and losing approximately one-half of the effective stroke of snubbing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The invention relates to pipe guides for snubbing units. When describing the present invention, all terms not defined herein have their common art-recognized meanings. To the extent that the following description is of a specific embodiment or a particular use of the invention, it is intended to be illustrative only, and not limiting of the claimed invention. The following description is intended to cover all alternatives, modifications and equivalents that are included in the spirit and scope of the invention, as defined in the appended claims.

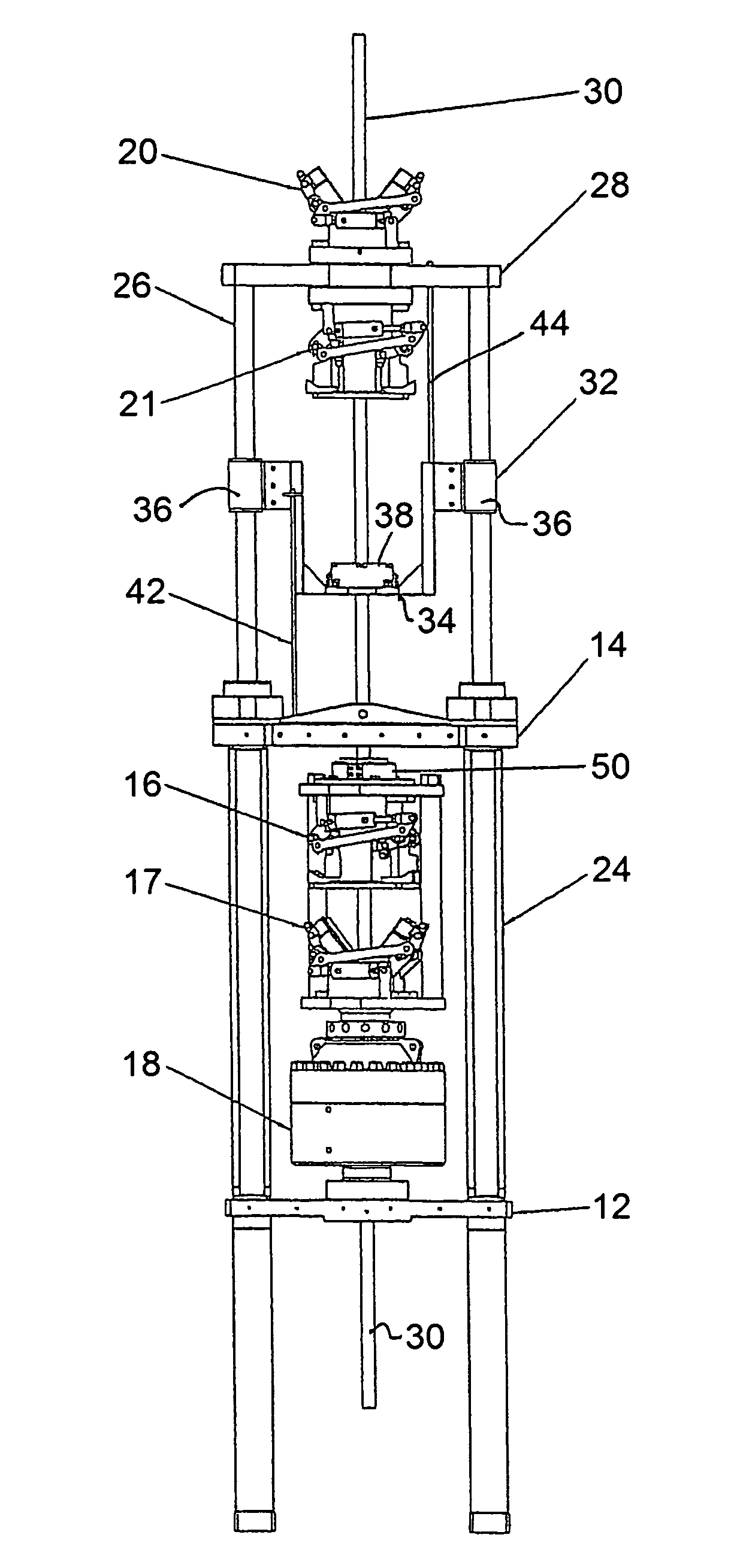

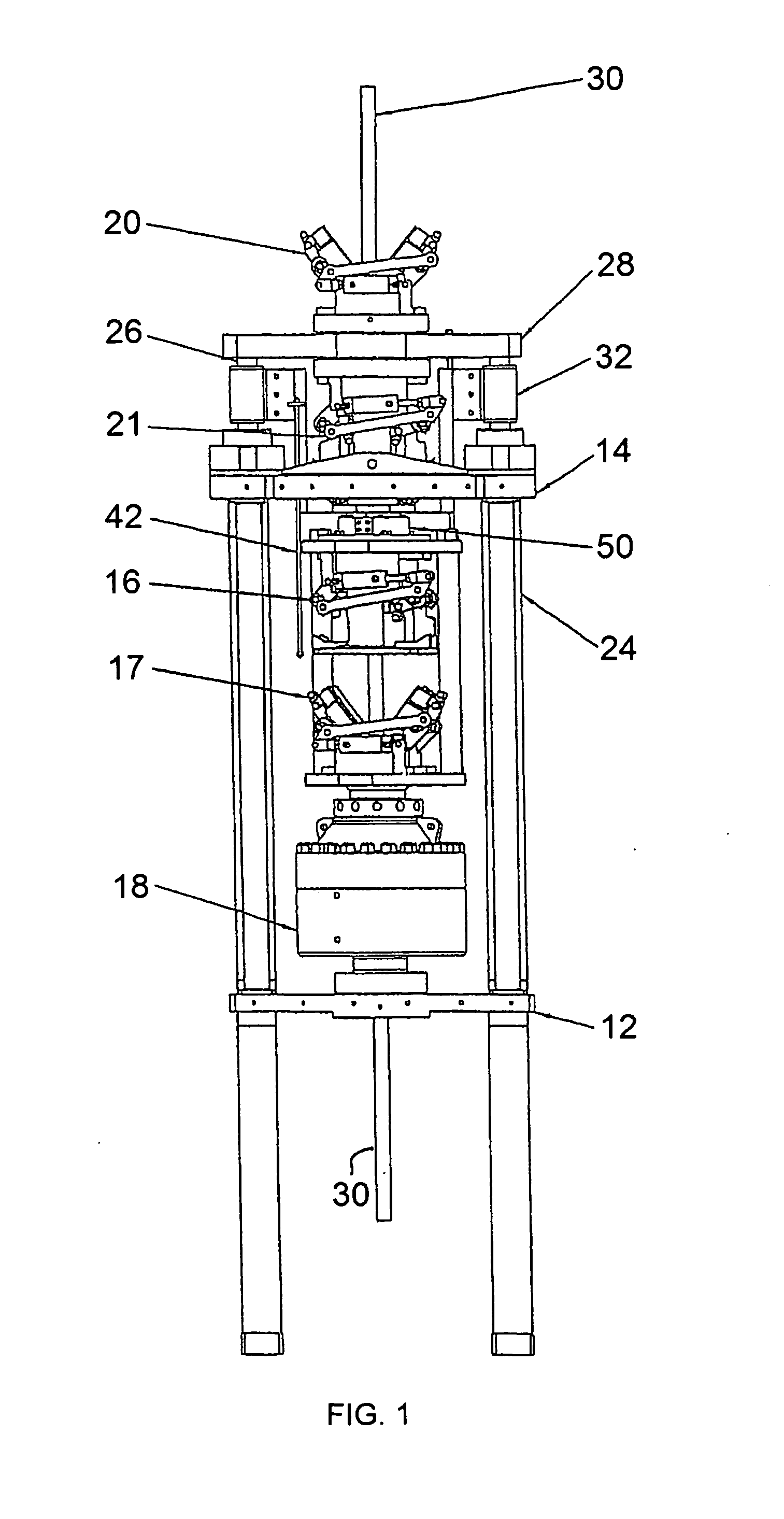

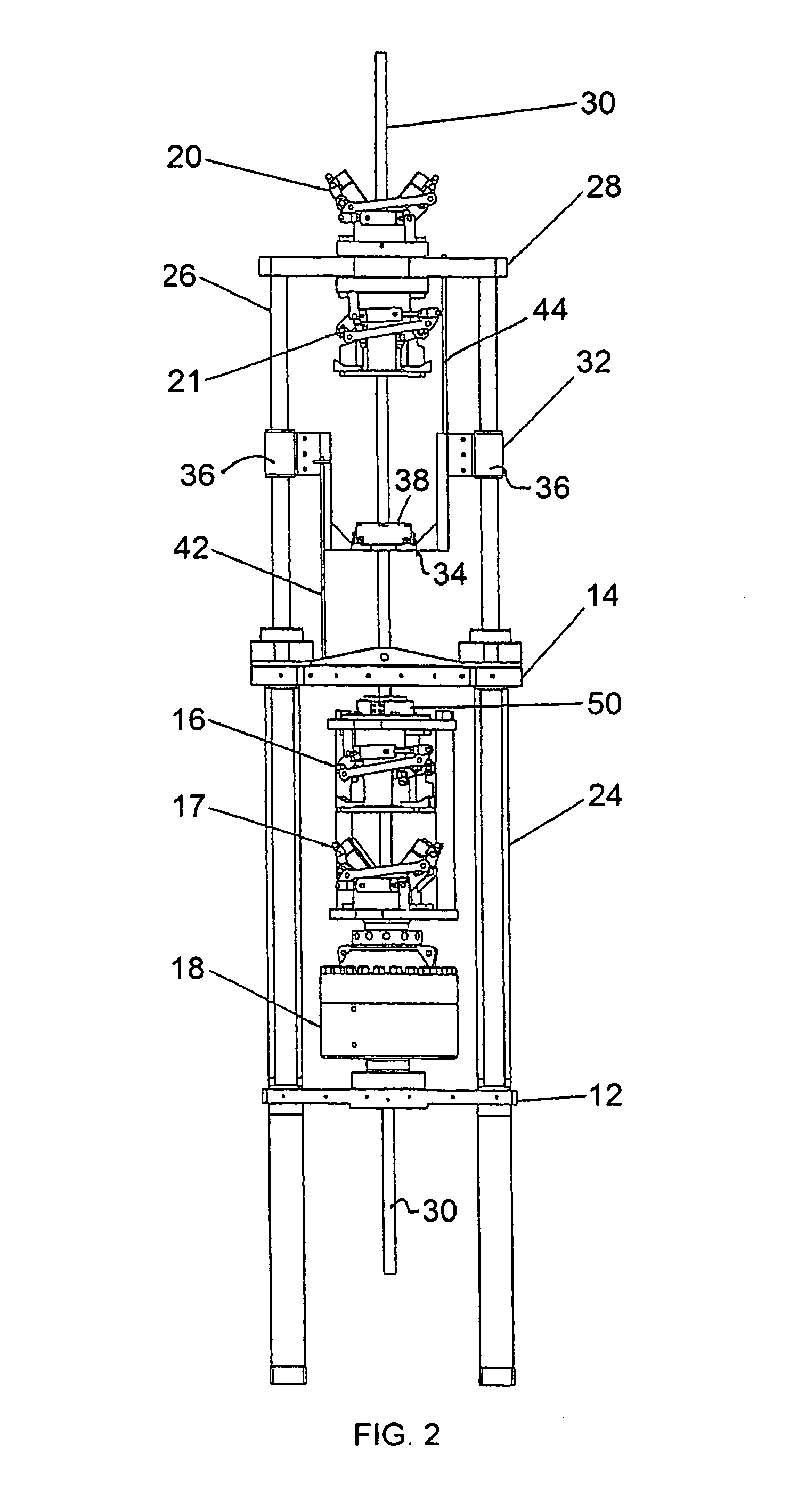

[0023]As shown in FIGS. 1 and 2, a snubbing unit (10) comprises a bottom jack plate (12) and a top jack plate (14). The snubbing unit (10) has stationary snubbing slips or pipe grippers (16, 17), provided with an underlying blow-out preventor (18), travelling snubbing slips or pipe grippers (20, 21) and a pair of hydraulic cylinder jacks (24) for moving the travelling snubbing slips (20) vertically towards and away from the stationary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com