Recycled paper smoothing device for used paper recycling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Embodiment 1

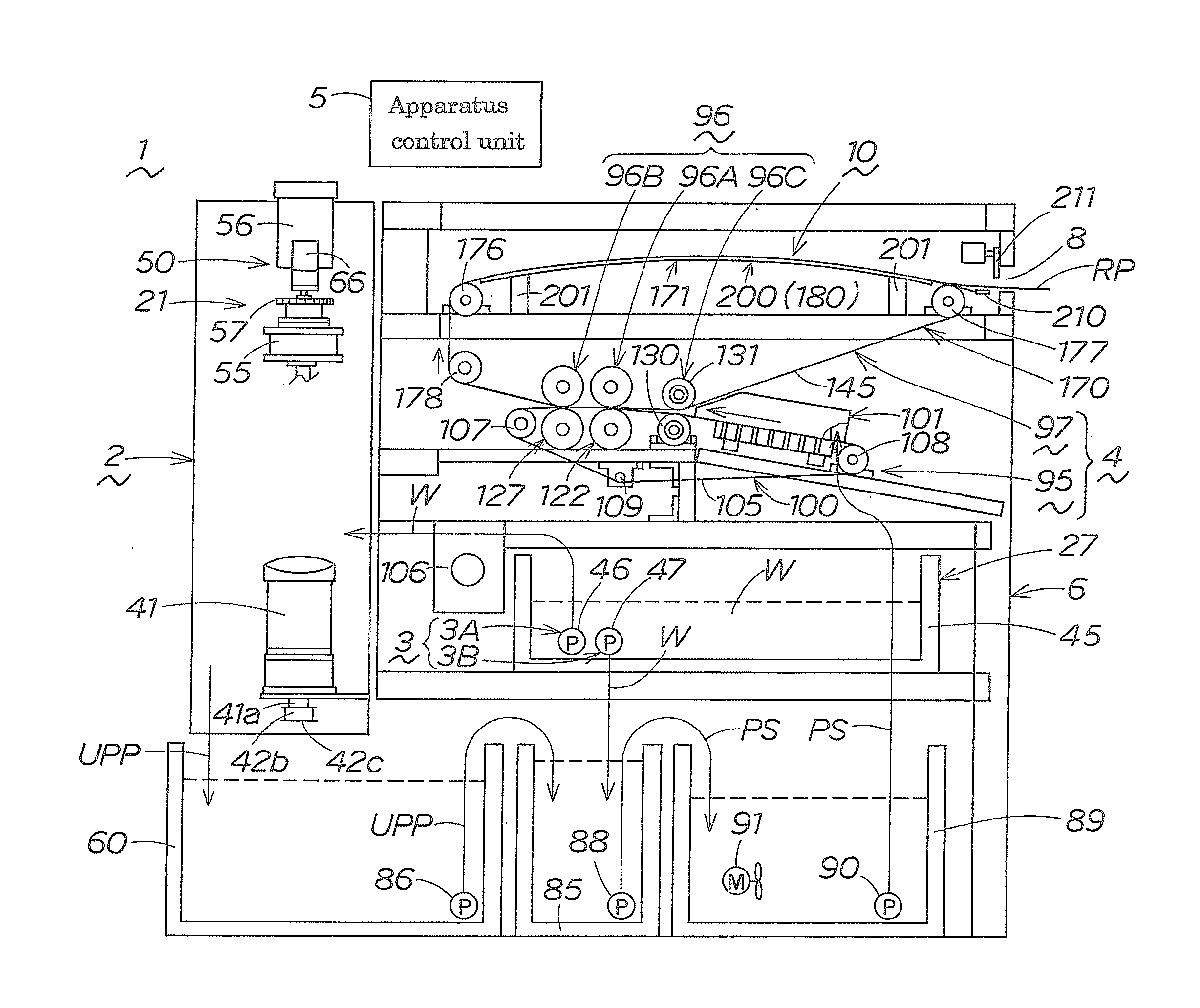

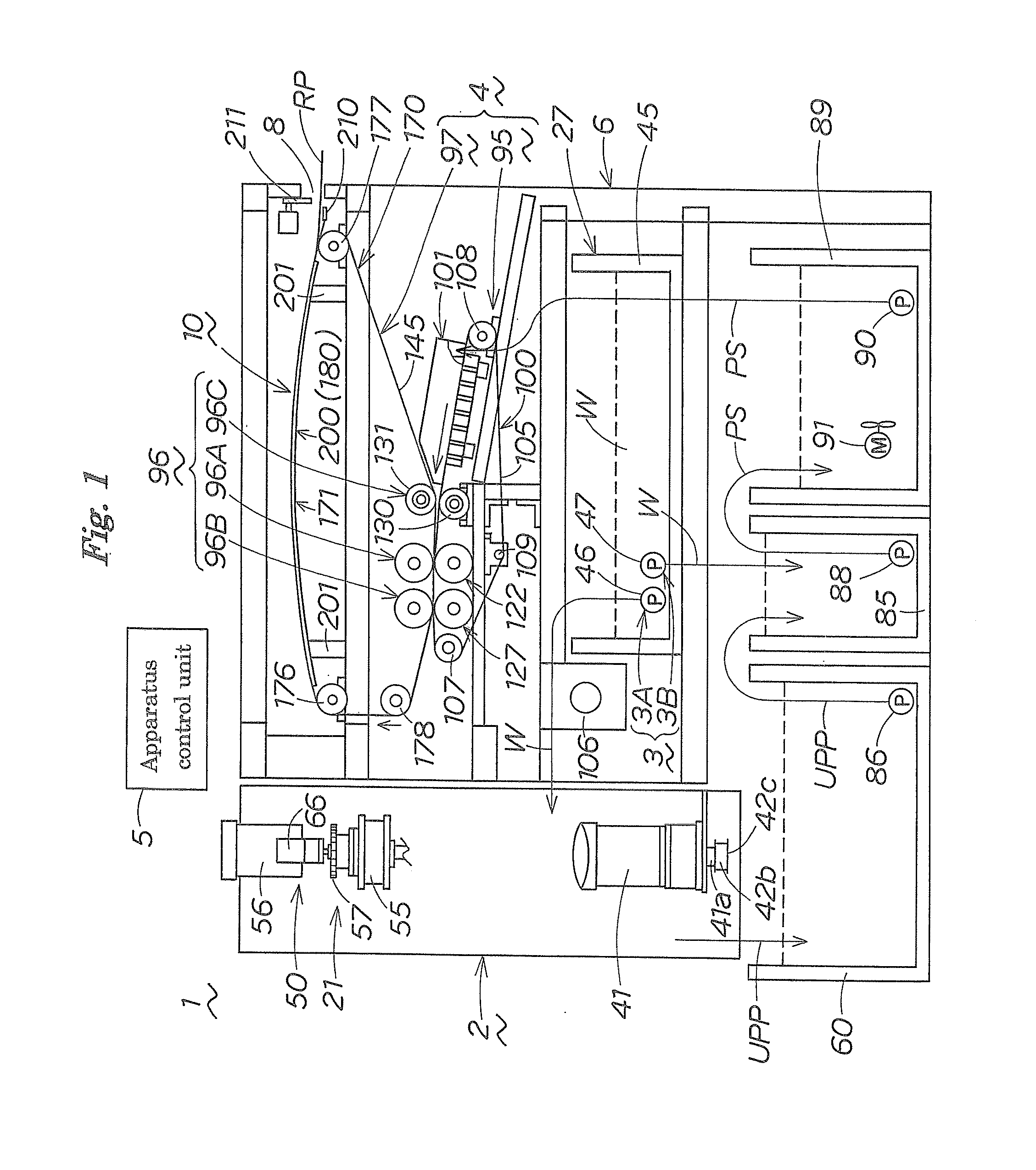

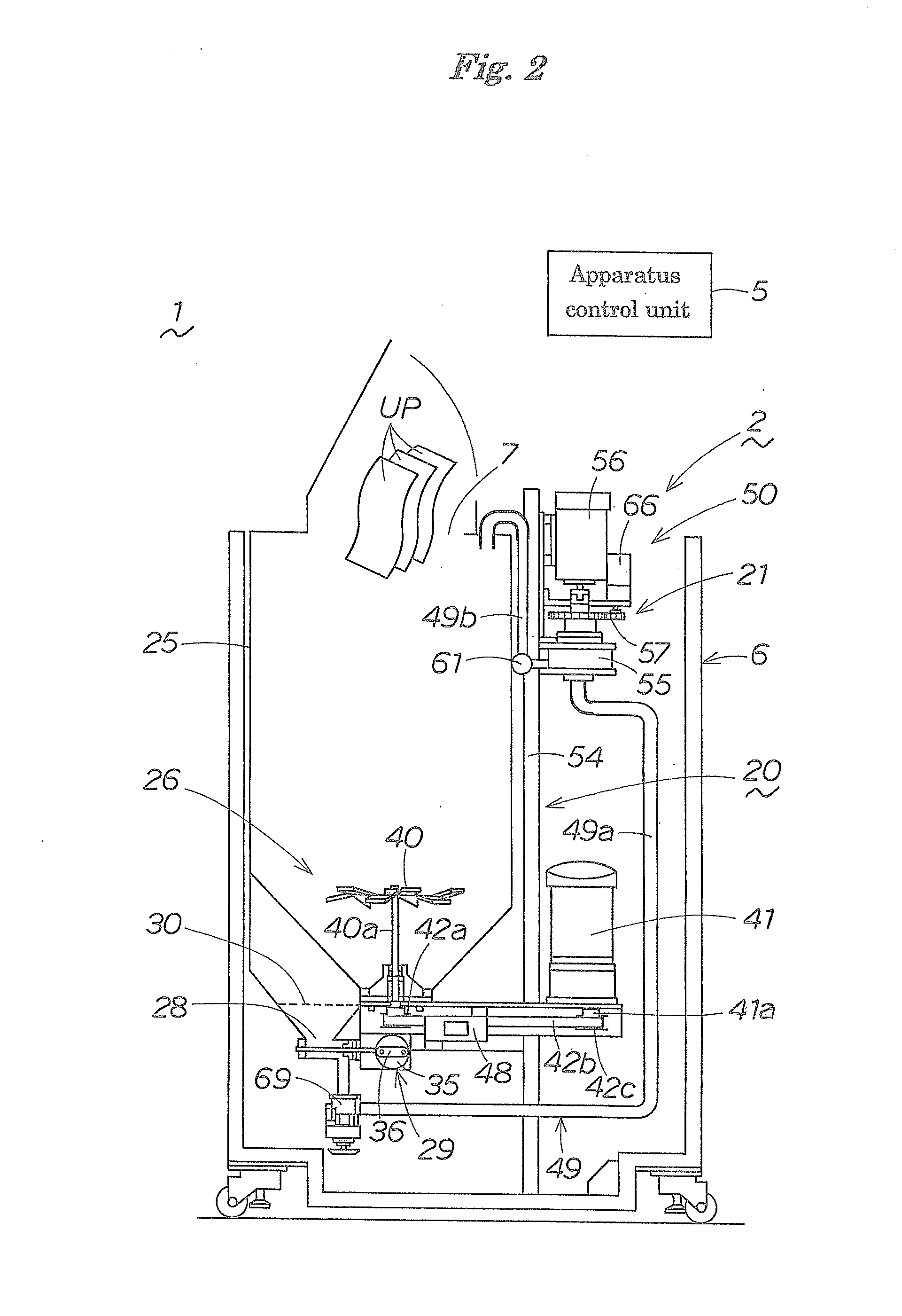

[0050]A used paper recycling apparatus of the present invention is shown in FIGS. 1 to 7, and this used paper recycling apparatus 1 is specifically installed at the site of origin of used paper, and is an apparatus for regenerating into a reusable paper at the same site, without disposing or discarding the used paper UP, and the used paper UP includes confidential documents from government offices and general corporate offices, personal letters from general household, and other used and unnecessary documents.

[0051]The used paper recycling apparatus 1 is as small as furniture size shown in FIG. 7, that is, small and compact similar to document rack, locker, desk, copier, personal computer, and other equipment installed in an office, and includes, as shown in FIG. 1, main units, specifically a pulp making unit 2, a pulp concentration adjustment unit 3, a paper making unit (paper making device) 4, and a device control unit (control unit) 5, and the paper making unit 4 inclu...

Example

Embodiment 2

[0181]This preferred embodiment is shown in FIG. 8 to FIG. 10, in which the configuration of the recycled paper smoothing unit (recycled paper smoothing device, recycled paper smoothing means) 10 of preferred embodiment 1 is modified.

[0182]That is, the recycled paper smoothing unit 10 of this preferred embodiment includes a pressing unit (pressing means) 250 for pressing the entire surface of the wet paper RP0 conveyed by the smooth surface belt 145 with a uniform pressure from the upper side, in addition to the configuration of preferred embodiment 1.

[0183]This pressing unit 250 is composed in a form of a covering belt conveyor specifically as shown in FIG. 9 and FIG. 10.

[0184]The covering belt conveyor 250 includes a covering belt 251 disposed and composed to run in a same horizontal direction in a state overlaid with the smooth surface belt 145, and the drive motor 106 for driving this covering belt 251. This drive motor 106 is used commonly as the drive source of the...

Example

Embodiment 3

[0204]This preferred embodiment is shown in FIG. 11, in which the configuration of the recycled paper smoothing unit (recycled paper smoothing device, recycled paper smoothing means) 10 of preferred embodiment 2 is slightly modified.

[0205]That is, a curved guide surface 200a of the belt guide unit 200 of the present preferred embodiment has a principal curved section curved upward to the running direction of the smooth surface belt 145, and an auxiliary curved section curved vertically upward to this principal curved section.

[0206]In other words, in the foregoing preferred embodiments 1 and 2, the belt guide unit 200 has the curved guide surface 200a having a principal curved section curved upward toward the running direction of the smooth surface belt 145, that is, the belt running direction section as shown in FIG. 6A and FIG. 10A, and this curved guide surface 200a is formed in a horizontal straight state in a section contour vertical to the principal curved section, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com