Method for eliminating positive pressure of baking furnace of color coating unit

A baking furnace and unit technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problem of serious smoke emission, smoke exhaust, non-discovered color coating baking furnace atmosphere positive pressure method, etc. problem, to achieve the effect of improving process and quality stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] In order for those skilled in the art to fully understand the technical solution of the present application, firstly, a specific introduction will be given to the color-coated steel plate production unit and production process.

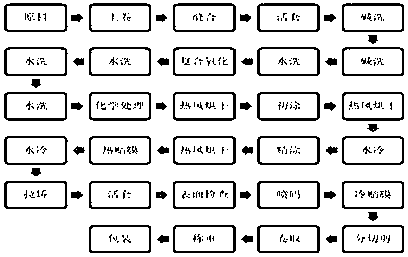

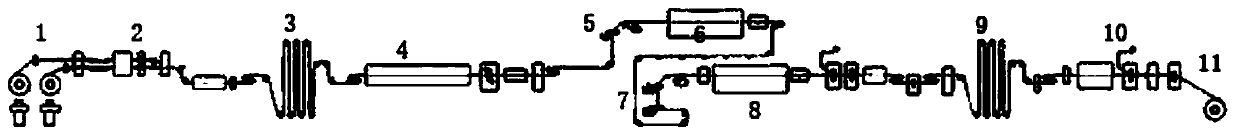

[0032] as attached figure 1 As shown, the color coated steel plate production unit, that is, the color coating unit, includes an uncoiler 1, a sewing machine 2, an inlet looper 3, a cleaning section 4, an initial coating machine 5, an initial coating oven 6, and Finish coating machine 7, finish coating baking oven 8, export looper 9, export shear 10, coiler 11. Conventional process flow as attached figure 2 shown.

[0033] Among them, the brief introduction of the production process is as follows: the incinerator uses coke oven gas to generate heat, and the hot air generated passes through the heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com