Montana long ranger rifle rest

a long ranger and rest technology, applied in the field of foldable rests, can solve the problems of reducing the range of action, and reducing the accuracy of firm rests, so as to enhance the rigidity of the target pivot tube attachment accessories and reduce the bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

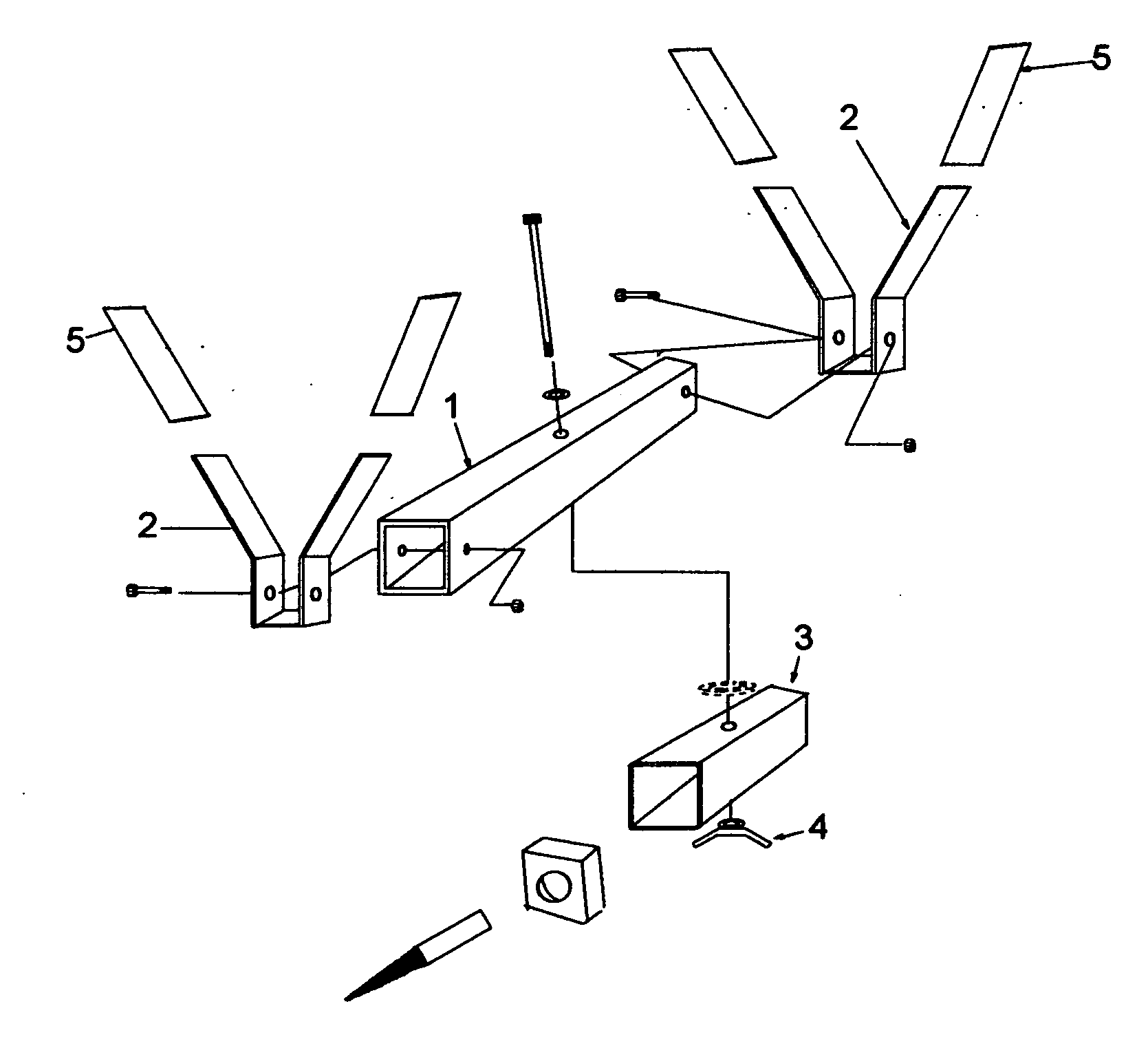

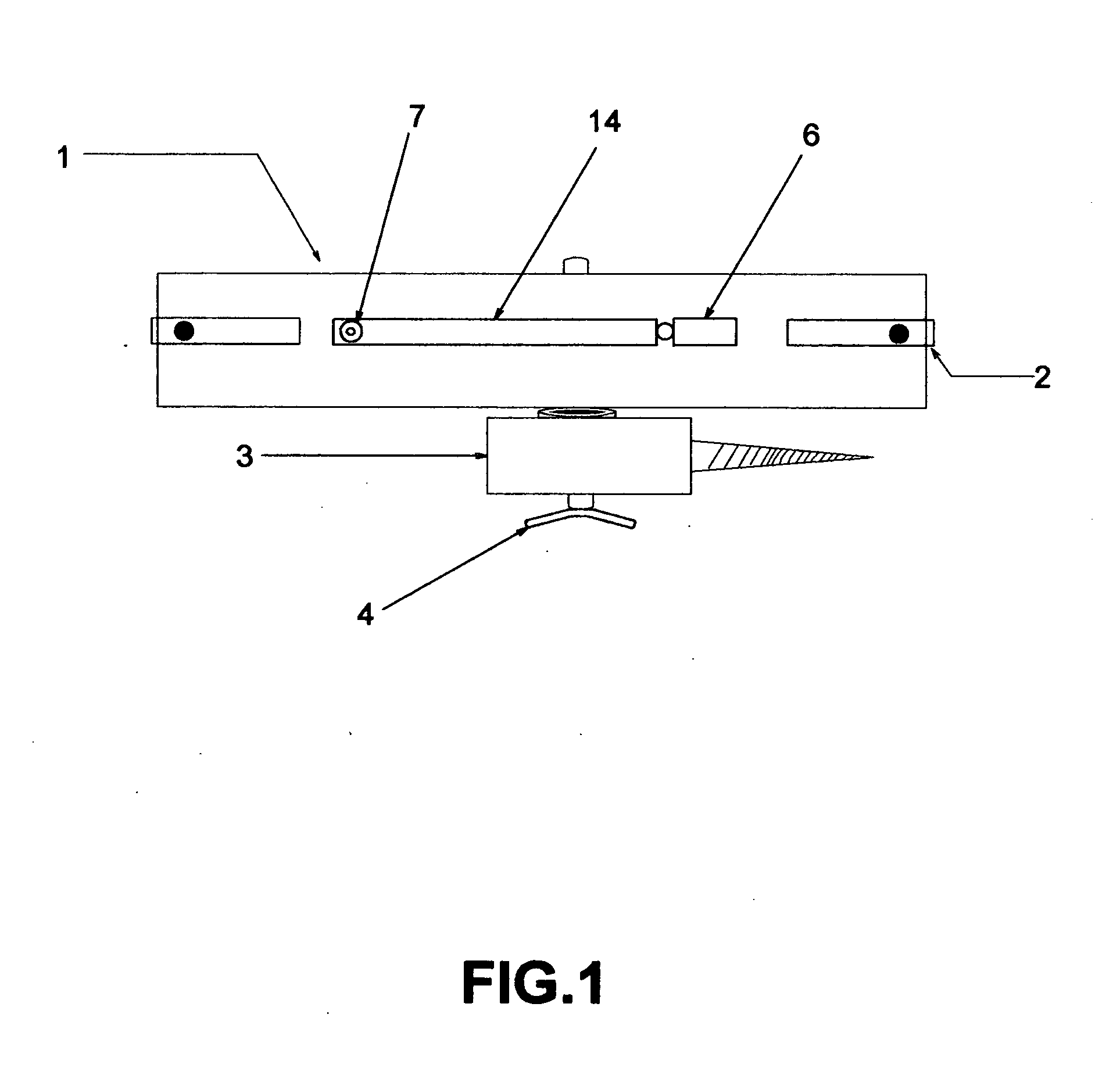

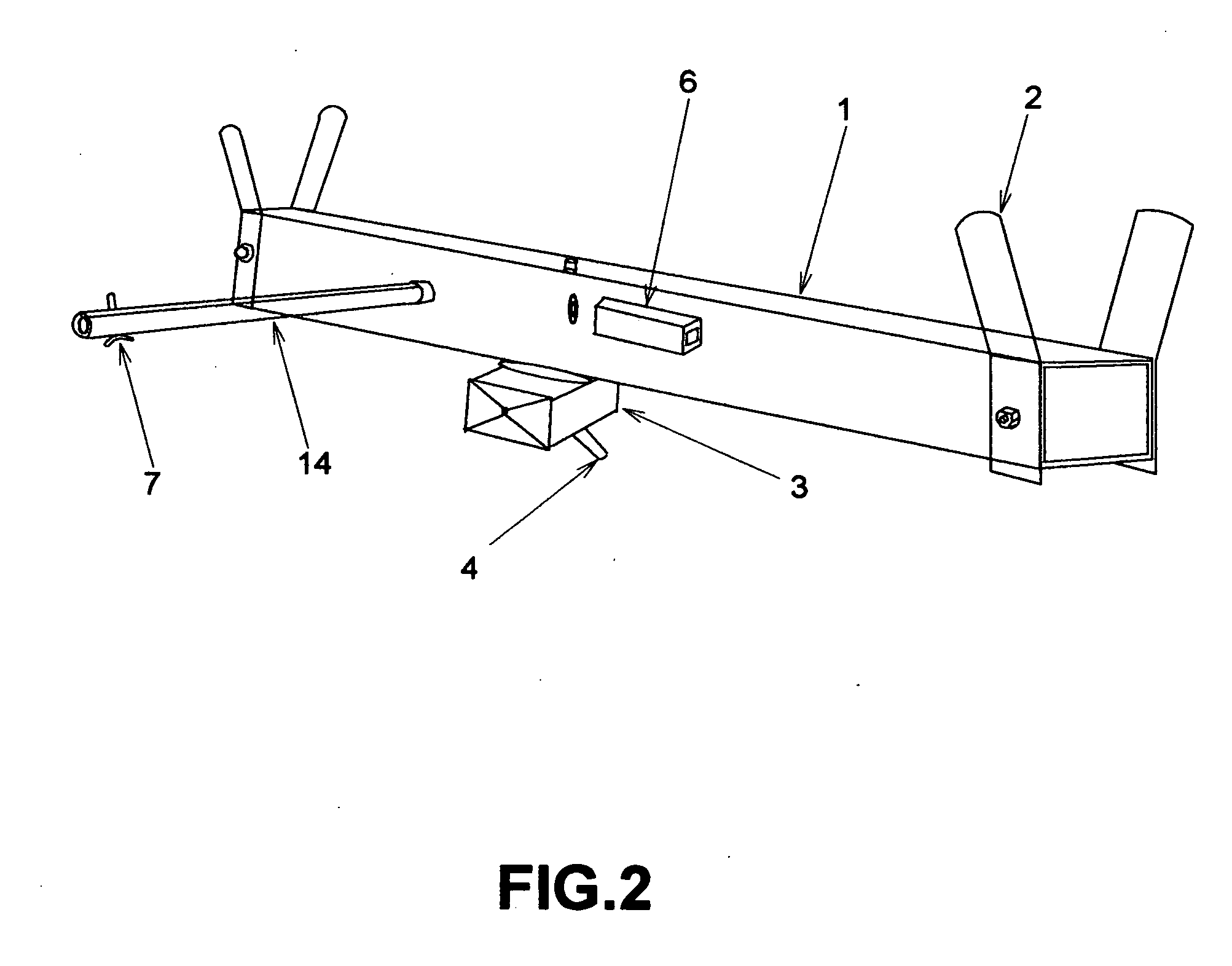

[0021]Referring to the drawings throughout several views corresponding to like elements, FIG. 1 indicates the folded rest in a position to be easily carried on a person. FIG. 2 indicates the rest in an open position whereby the screw arm is loosened from the rifle support beam by turning the adjustment wing handle, permitting the screw arm to be turned either left or right, positioning the screw arm for tree attachment. When the appropriate position of the arm is made, the adjustment wing handle is tightened. FIG. 2 indicates the screw arm in a right angle position to the rifle support beam whereby the entire rest can be used to turn the screw into a tree. FIG. 3, refers to the rest in the attached position to a tree utilizing the screw arm attachment accessory. FIG. 2 indicates the front and rear rifle support prongs pivoted upwards from the folded position to receive the rifle. FIG. 3A indicates the camera / spotting scope bracket attached to the rifle support beam after it is remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com