Automatic tonometer tip disinfection apparatus

a disinfection apparatus and automatic technology, applied in the field of automatic tonometer tip disinfection apparatus, can solve the problems of plastic corrosion, substantial cost and inconvenience, and require replacement at substantial cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

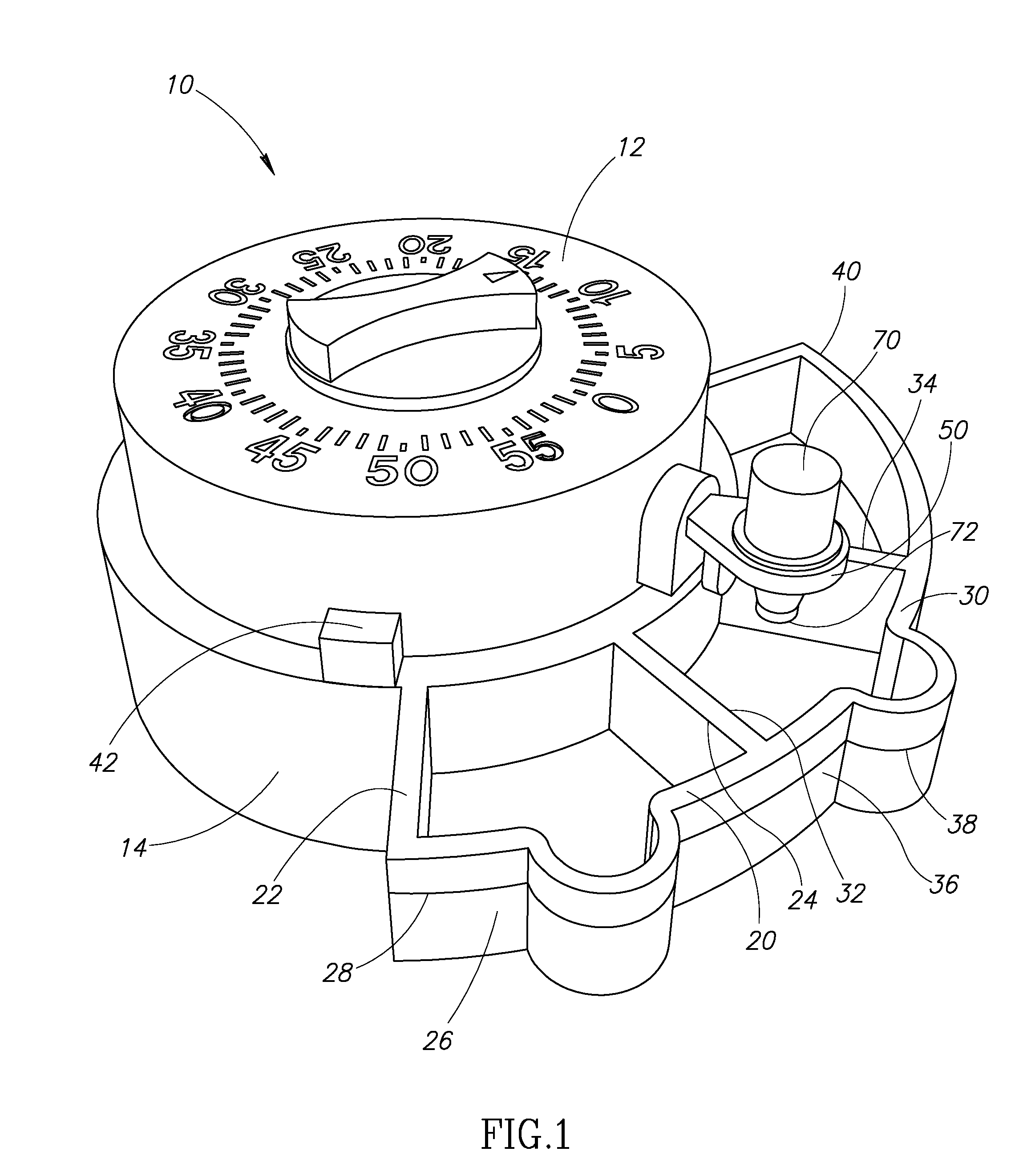

[0013]Referring to FIG. 1, the apparatus 10 includes a mechanical rotating timer 12 preferably mounted to a supportive base 14, for example, made of a plastic or like material. The base 14 supports or is otherwise affixed to or associated with a first basin 20 having a front wall 22, a back wall 24, and a side wall 26 preferably including a fluid level mark 28, which basin holds a disinfecting solution, for example, peroxide. In one embodiment, the fluid level of the rinsing solution is set to be higher than the fluid level of the disinfecting solution in order to ensure that the disinfecting solution is completely removed from the tonometer tip. The base 14 supports or is otherwise affixed to or associated with a second basin 30 having a front wall 32 preferably adjacent to or coextensively formed with the back wall 24 of the first basin 20, a preferably raised back wall 34, and a side wall 36 preferably including a fluid level mark 38, which basin holds a rinsing solution, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com