Mixing package and methods of forming and using same

a technology of mixing package and mixing container, which is applied in the direction of packaging, transportation and packaging, container/bottle construction, etc., to achieve the effect of high squeezing pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

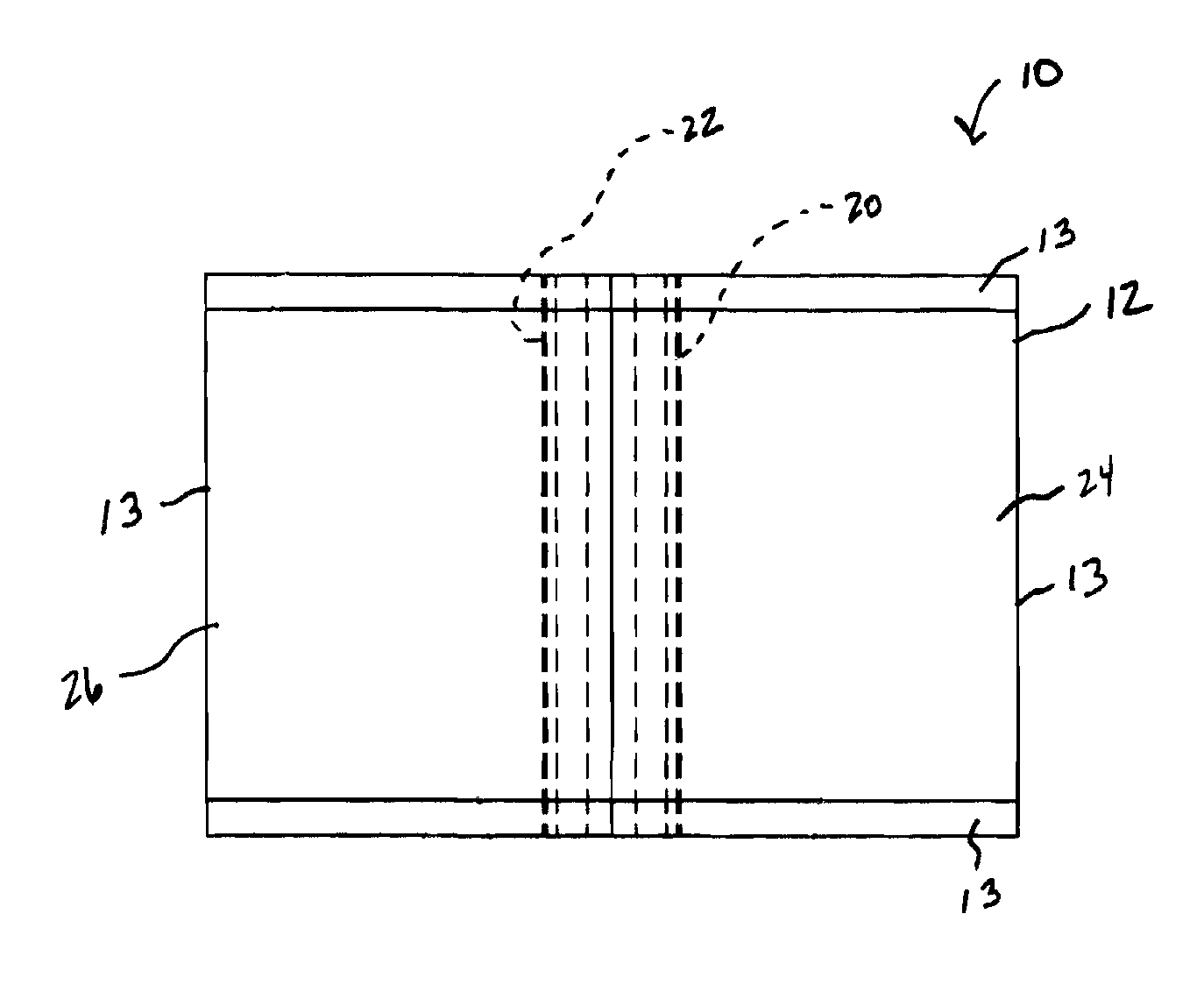

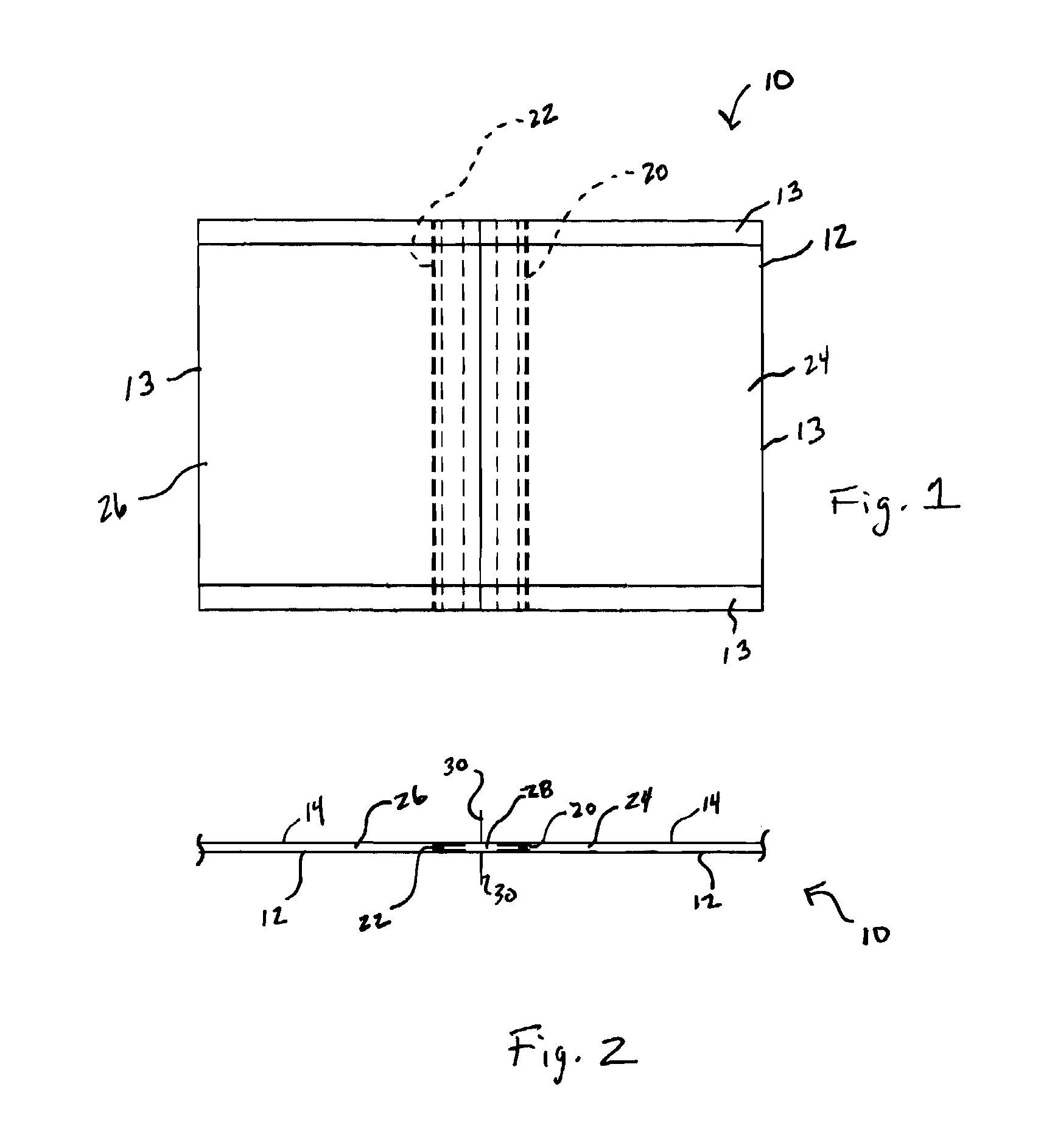

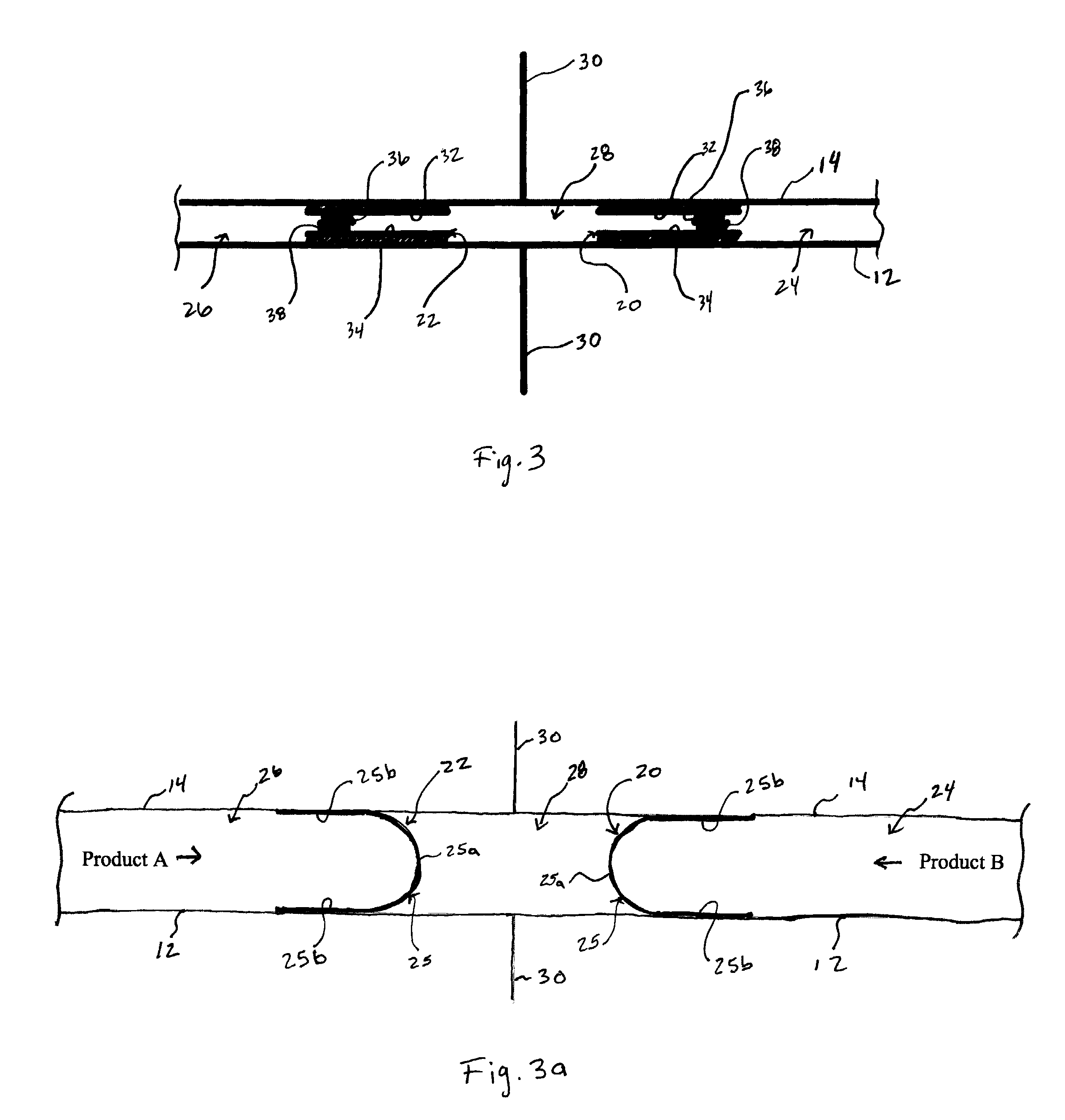

[0020]Referring generally to FIGS. 1-7, a flexible package 10 in accordance with the present invention, and the steps for using the flexible package 10, are shown or described. The package 10 generally includes a first or front panel portion 12 and a second or back panel portion 14 configured to define a package interior 9 adapted to hold contents or product 11. The package 10 can further include a bottom panel portion and one or more side panel portions. The panel portions can be joined to form or define an inner cavity of the main package 10 for holding, transporting, or otherwise containing material contents. The material contents can include solids, fluids (e.g., liquid or gaseous contents), powders, gels, granular substances, foods, and like substances, materials or contents.

[0021]Each of the panel portions can include internal sealant surfaces. The joining of the front and back panels 12, 14 can create corresponding side or seal edges and top and bottom seals. Alternatively, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com